The short answer is that CNC machined Polytetrafluoroethylene (PTFE) has become an indispensable material across a vast range of high-stakes industries. Its unique properties have enabled critical innovations in the aerospace, medical, automotive, electronics, and chemical processing sectors. The precision of CNC machining allows this versatile polymer to be shaped into complex components that perform reliably where other materials fail.

The widespread adoption of CNC machined PTFE is not due to a single trait, but its rare combination of properties. Its ability to simultaneously offer extreme chemical inertness, high-temperature stability, excellent electrical insulation, and an incredibly low coefficient of friction makes it a unique problem-solver for the most demanding engineering challenges.

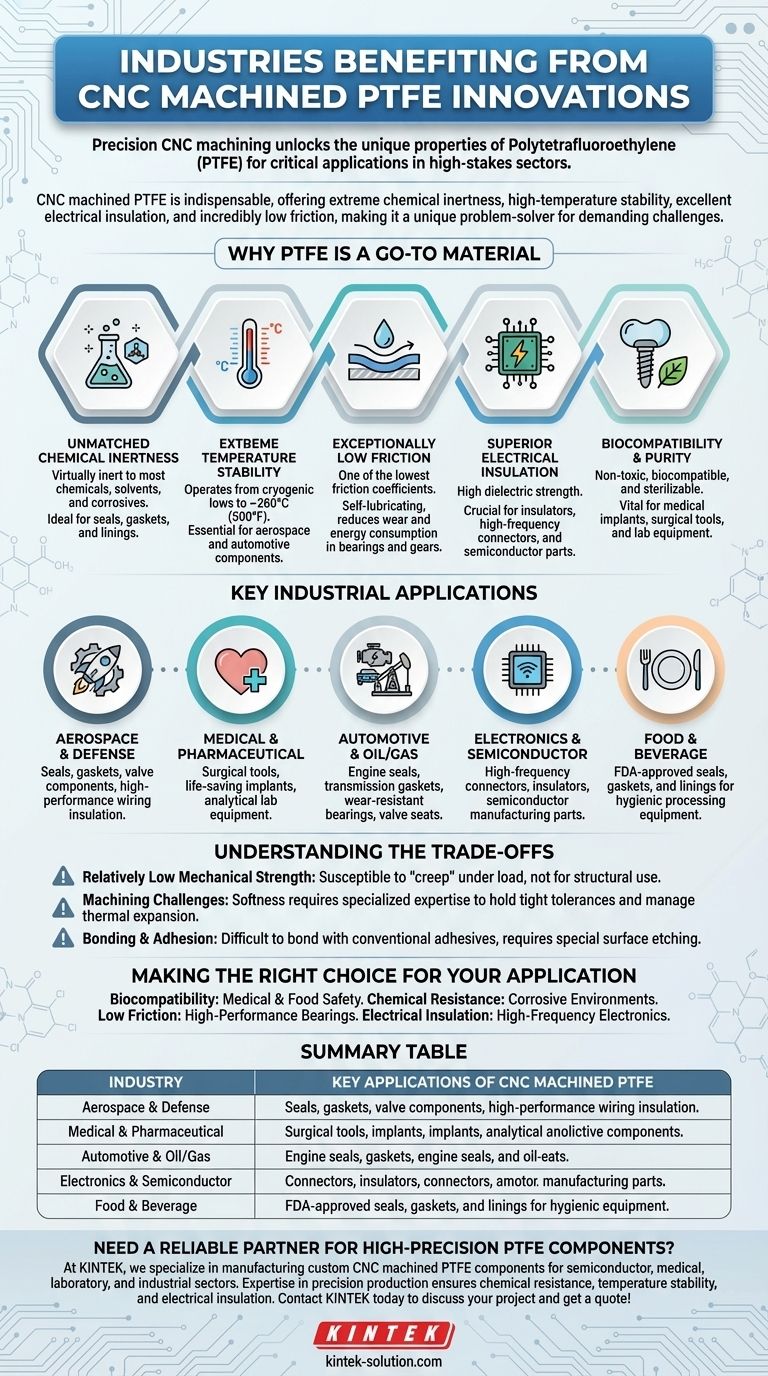

Why PTFE is a Go-To Material for Critical Applications

The value of PTFE is rooted in a set of core properties that, when combined with the precision of CNC machining, create high-performance components. Understanding these attributes reveals why it is so heavily relied upon.

Unmatched Chemical Inertness

PTFE is virtually inert, meaning it does not react with the vast majority of industrial chemicals, solvents, and corrosive agents. This makes it an ideal material for seals, gaskets, and linings in chemical processing, oil and gas, and pharmaceutical equipment.

Extreme Temperature Stability

This material maintains its integrity across a very wide temperature range. It can operate continuously in harsh environments, from cryogenic lows to highs of around 260°C (500°F), a critical requirement for aerospace and automotive engine components.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material, often compared to wet ice on wet ice. This "non-stick" or self-lubricating property is essential for creating efficient bearings, gears, and seals that reduce wear and energy consumption.

Superior Electrical Insulation

As an excellent electrical insulator with high dielectric strength, PTFE is crucial in the electronics and semiconductor industries. It is used for high-performance wire insulation, connectors, and other components where signal integrity is paramount.

Biocompatibility and Purity

PTFE is non-toxic and biocompatible, meaning it can be used in direct contact with the human body without causing an adverse reaction. This, along with its ability to be sterilized, makes it a vital material for medical implants, surgical instruments, and laboratory equipment.

A Closer Look at Key Industrial Applications

The theoretical benefits of PTFE translate directly into tangible solutions across multiple sectors. The precision of CNC machining is what allows engineers to fully leverage these properties in complex, custom-designed parts.

Aerospace & Defense

In this sector, failure is not an option. CNC machined PTFE is used for seals, gaskets, and valve components in fuel systems and hydraulic lines due to its chemical resistance and performance under extreme temperatures and pressures. Its insulating properties are also vital for high-performance wiring.

Medical & Pharmaceutical

The biocompatibility and purity of PTFE are paramount here. It is machined into surgical tools, life-saving implants like vascular grafts, and analytical lab equipment. Its non-stick surface prevents contamination and ensures the smooth operation of precision instruments.

Automotive & Oil/Gas

High-wear and high-pressure environments demand durable materials. PTFE is machined into engine seals, transmission gaskets, and wear-resistant bearings that require no external lubrication. In the oil and gas industry, it is used for valve seats and seals that must withstand corrosive chemicals and high pressures.

Electronics & Semiconductor

To create smaller, more powerful devices, components must provide reliable electrical insulation. CNC machined PTFE is used for insulators, high-frequency connectors, and semiconductor manufacturing equipment where both electrical performance and chemical purity are critical.

Food & Beverage

Compliance with safety standards is essential. Because PTFE is FDA-approved and non-toxic, it is used for seals, gaskets, and linings in food processing equipment. Its non-stick surface simplifies cleaning and prevents material buildup, ensuring a hygienic environment.

Understanding the Trade-offs

No material is perfect, and providing objective advice means acknowledging limitations. While PTFE is a remarkable problem-solver, it has specific trade-offs that engineers must consider.

Relatively Low Mechanical Strength

Compared to metals or other engineering plastics, PTFE is a soft material. It can be susceptible to "creep," or deforming over time when subjected to a constant load. This makes it unsuitable for high-load structural applications.

Machining Challenges

While highly machinable, the softness of PTFE can make holding extremely tight tolerances a challenge without specialized expertise. The material can also experience thermal expansion, which must be accounted for during the machining process to ensure final part accuracy.

Bonding and Adhesion

The same non-stick property that makes PTFE so valuable also makes it very difficult to bond using conventional adhesives. The surface must undergo a special etching process to allow for effective adhesion.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary demands of your project. PTFE is not a universal solution, but it is an unparalleled one for specific challenges.

- If your primary focus is biocompatibility or food safety: PTFE is an industry standard for medical implants, lab equipment, and food processing components due to its inert and non-toxic nature.

- If your primary focus is extreme chemical resistance: PTFE is the definitive choice for seals, gaskets, and linings that will be exposed to highly corrosive chemicals.

- If your primary focus is low friction and wear resistance: PTFE's self-lubricating properties make it ideal for high-performance bearings, bushings, and seals where reducing friction is key.

- If your primary focus is high-frequency electrical insulation: PTFE provides exceptional dielectric properties needed for critical connectors and insulators in electronics and telecommunications.

Ultimately, CNC machined PTFE excels where a combination of extreme environmental resistance and precision is non-negotiable.

Summary Table:

| Industry | Key Applications of CNC Machined PTFE |

|---|---|

| Aerospace & Defense | Seals, gaskets, valve components, high-performance wiring insulation |

| Medical & Pharmaceutical | Surgical tools, implants (e.g., vascular grafts), analytical lab equipment |

| Automotive & Oil/Gas | Engine seals, transmission gaskets, wear-resistant bearings, valve seats |

| Electronics & Semiconductor | High-frequency connectors, insulators, semiconductor manufacturing parts |

| Food & Beverage | FDA-approved seals, gaskets, and linings for hygienic processing equipment |

Need a reliable partner for high-precision PTFE components?

At KINTEK, we specialize in manufacturing custom CNC machined PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures your parts meet the most demanding requirements for chemical resistance, temperature stability, and electrical insulation.

Whether you need prototypes or high-volume orders, we deliver solutions you can trust. Contact KINTEB today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support