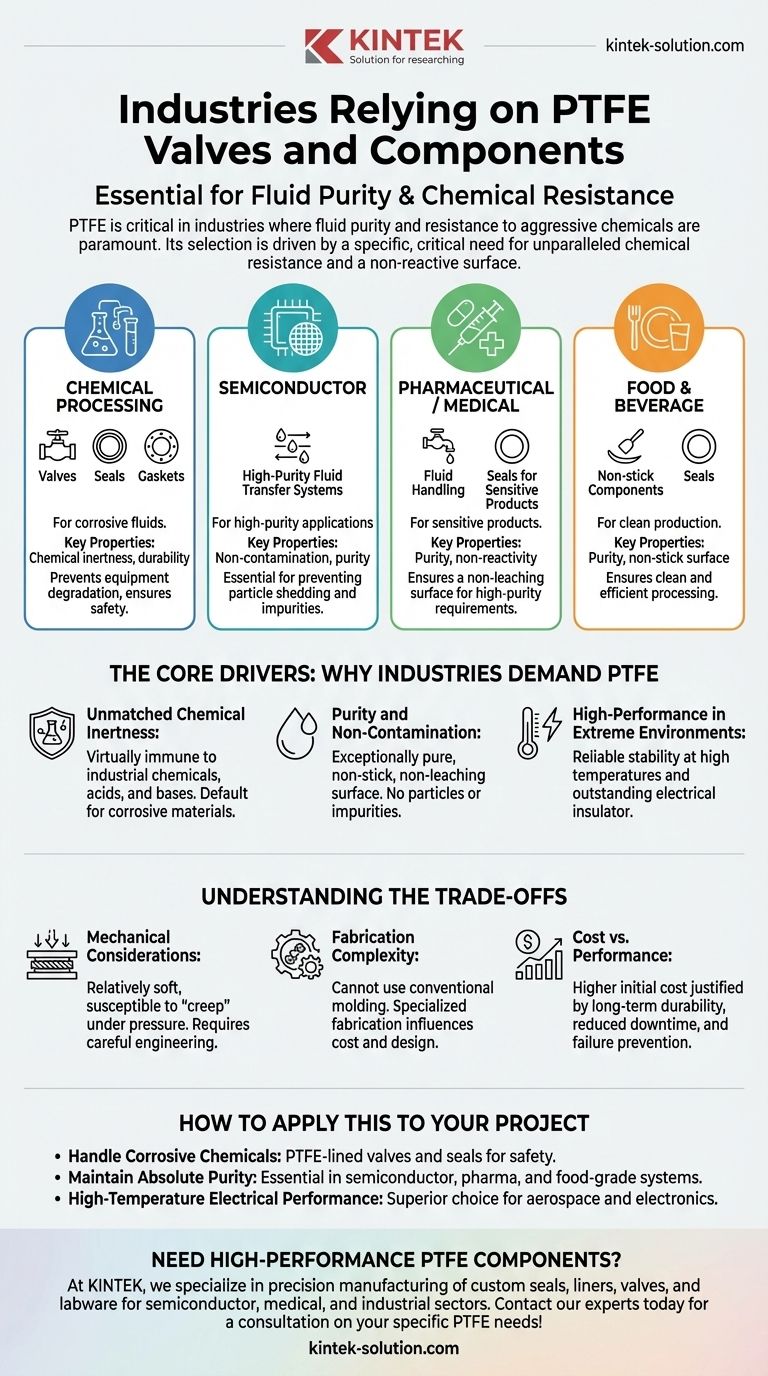

In short, Polytetrafluoroethylene (PTFE) components are essential in any industry where fluid purity and resistance to aggressive chemicals are critical. The most prominent users are the chemical processing, semiconductor, pharmaceutical, and food and beverage industries, which rely on PTFE for its extreme inertness and non-contaminating properties.

The selection of PTFE is less about a specific industry and more about a specific, critical need. Industries handling ultra-pure, highly corrosive, or sensitive fluids universally depend on PTFE for its unparalleled chemical resistance and non-reactive surface.

The Core Drivers: Why Industries Demand PTFE

The widespread adoption of PTFE is not accidental. It stems from a unique combination of material properties that solve expensive and high-stakes problems across various sectors.

Unmatched Chemical Inertness

PTFE is virtually immune to attack from almost all industrial chemicals, acids, and bases. This makes it the default choice for components that will be in constant contact with corrosive materials.

This property is mission-critical for the chemical processing, petrochemical, oil and gas, and water treatment industries. In these fields, PTFE-lined valves, gaskets, and seals prevent equipment degradation, ensure process safety, and extend operational life.

Purity and Non-Contamination

PTFE is exceptionally pure and has a non-stick, non-leaching surface. It does not shed particles or impart impurities into the media it contacts, which is a non-negotiable requirement in high-purity applications.

This is why the semiconductor, pharmaceutical, and medical device industries rely heavily on PTFE for fluid transfer systems. In food processing and beverage applications, its non-stick nature also ensures clean and efficient production.

High-Performance in Extreme Environments

Beyond its chemical properties, PTFE performs reliably under extreme conditions. It maintains stability at high temperatures and is an outstanding electrical insulator.

These characteristics make it vital for the aerospace and electronics sectors, where it is used for high-performance wiring insulation, connectors, and seals that must function flawlessly under demanding circumstances. Similarly, the automotive industry uses it for seals, gaskets, and low-friction bearings.

Understanding the Trade-offs

While its benefits are significant, PTFE is a specialized material, and understanding its limitations is key to successful implementation.

Mechanical Considerations

PTFE is a relatively soft material. It can be susceptible to "creep" or cold flow under sustained pressure, which requires careful engineering and design, especially for high-pressure seals.

Fabrication Complexity

Unlike common plastics, PTFE cannot be processed using conventional melt-extrusion or molding techniques. This specialized fabrication can influence the cost and design possibilities of components.

Cost vs. Performance

As a high-performance polymer, PTFE components carry a higher initial cost than those made from commodity plastics. This cost is justified by its long-term durability, reduced downtime, and the prevention of catastrophic failures in critical applications.

How to Apply This to Your Project

Your decision to use PTFE should be driven entirely by the operational demands of your specific application.

- If your primary focus is handling corrosive chemicals: PTFE-lined valves and seals are the industry standard for preventing equipment failure and ensuring safety.

- If your primary focus is maintaining absolute purity: PTFE components are essential in semiconductor, pharmaceutical, and food-grade systems to prevent product contamination.

- If your primary focus is high-temperature electrical performance: PTFE is a superior choice for critical wiring, seals, and connectors in aerospace and electronics.

Ultimately, PTFE is the material of choice when performance, safety, and reliability cannot be compromised.

Summary Table:

| Industry | Primary Use Case for PTFE | Key PTFE Properties Utilized |

|---|---|---|

| Chemical Processing | Valves, seals, gaskets for corrosive fluids | Chemical inertness, durability |

| Semiconductor | High-purity fluid transfer systems | Non-contamination, purity |

| Pharmaceutical/Medical | Fluid handling, seals for sensitive products | Purity, non-reactivity |

| Food & Beverage | Non-stick components, seals | Purity, non-stick surface |

| Aerospace/Automotive | High-temp seals, wiring insulation | Temperature stability, electrical insulation |

Need high-performance PTFE components tailored to your industry's demands?

At KINTEK, we specialize in the precision manufacturing of PTFE components—including custom seals, liners, valves, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical need for reliability, purity, and chemical resistance in your applications.

Our expertise in custom fabrication ensures you get the exact solution, from prototypes to high-volume orders, that meets your stringent requirements. Let us help you enhance your process safety and efficiency.

Contact our experts today for a consultation on your specific PTFE needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is dimensional stability important for PTFE rod in heavy-load applications? Prevent Failure & Ensure Reliability

- What are PTFE O-rings and what are they commonly used for? Solve Sealing Challenges in Harsh Environments

- How do stainless steel impellers compare to PTFE impellers in terms of non-stick properties? Prevent Residue & Buildup

- What makes PTFE a popular choice for sealing applications? Discover Its Superior Chemical & Temperature Resistance

- What are the performance advantages of PTFE as a gasketing material? Superior Chemical & Thermal Resistance for Demanding Seals

- What is the purpose of PTFE etching? Unlock Bondable Surfaces for Your Components

- What are the advantages of PTFE sliding bearings in terms of size and design flexibility? Achieve Compact, Custom Solutions

- How do PTFE bearings benefit laboratory instruments? Ensure Purity and Precision in Your Lab