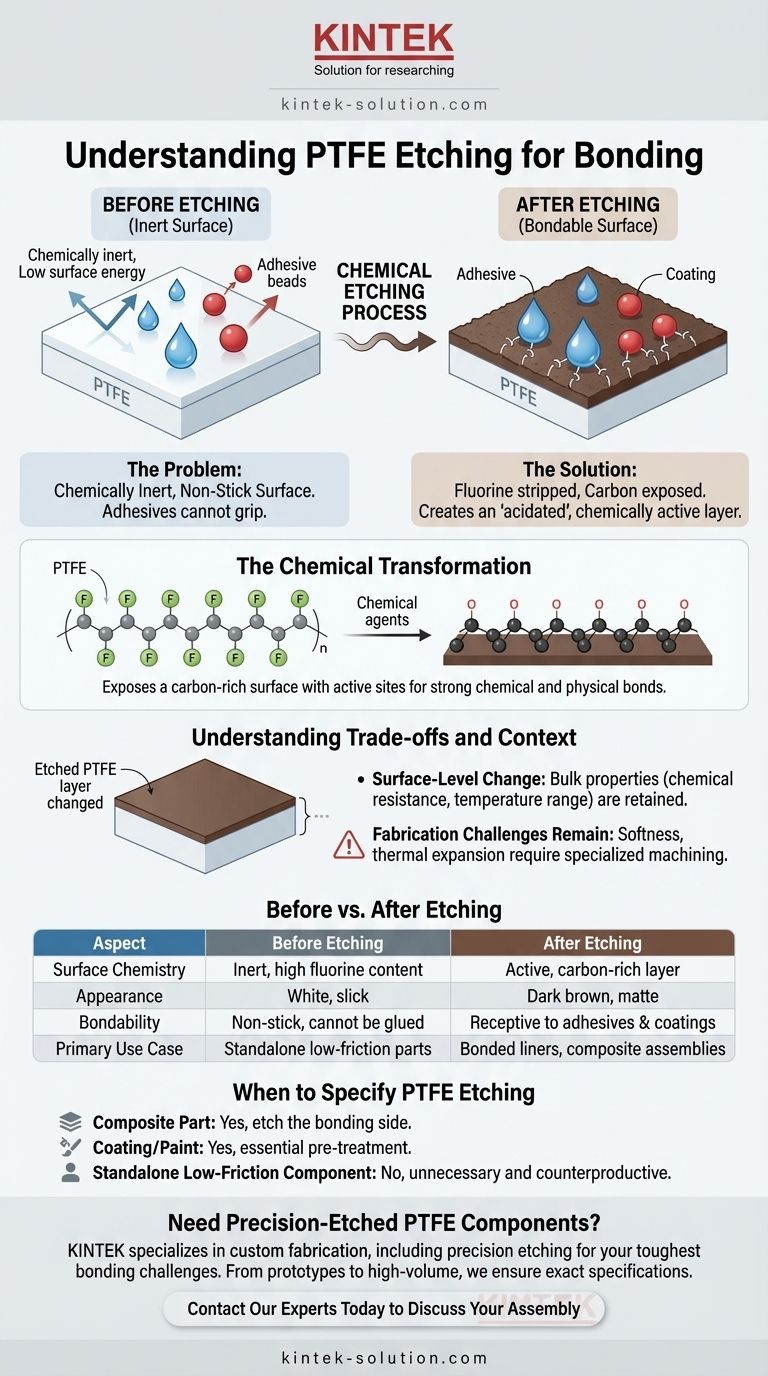

At its core, the purpose of PTFE etching is to chemically alter the material's famously non-stick surface to make it bondable. This process transforms the inert, slick surface into a dark brown, "acidated" layer that adhesives and coatings can securely grip, unlocking applications that would otherwise be impossible.

The fundamental challenge with PTFE is that its most valuable property—its chemical inertness and low friction—also prevents it from being glued to other materials. Etching is the critical surface treatment that solves this problem, enabling PTFE to be integrated into composite parts and assemblies.

The Fundamental Problem: PTFE's Natural Inertness

Polytetrafluoroethylene (PTFE) is a material of extremes. Its unique properties make it incredibly useful, but they also create significant fabrication challenges.

Why Standard PTFE Doesn't Stick

The surface of PTFE is chemically inert and has extremely low surface energy. This is why it's used for non-stick coatings.

Molecules, including those in adhesives, simply can't find anything on the PTFE surface to latch onto, causing them to bead up and wipe away instead of forming a bond.

The Need for Surface Modification

To use PTFE as a bonded liner, a protective coating, or part of a multi-material assembly, its surface must be fundamentally changed. You cannot force PTFE to stick; you must first modify it to be receptive to bonding.

How PTFE Etching Solves the Bonding Challenge

Etching is not a coating or an addition; it is a chemical transformation of the existing PTFE surface.

The Chemical Transformation

The etching process uses a chemical agent to strip fluorine atoms from the PTFE polymer chains on the surface.

This exposes a layer of carbon atoms, creating a visually distinct, dark brown, and chemically receptive surface. This is the "acidated" layer that enables bonding.

Creating a Bondable Surface

This new carbonaceous layer has active sites that can form strong chemical and physical bonds with various adhesives.

Essentially, etching creates a microscopic, chemically active anchor field on the surface, allowing glues and coatings to adhere permanently.

Understanding the Trade-offs and Context

While etching is a powerful solution, it's crucial to understand its context and limitations.

A Surface-Level Change

Etching only affects the outermost layer of the PTFE. The bulk of the material beneath the surface retains its original properties, such as excellent chemical resistance and a wide operating temperature range.

Broader Fabrication Challenges

Solving the bonding problem with etching is just one part of working with PTFE. The material's softness, high thermal expansion, and tendency to creep under stress make precision machining difficult.

Achieving tight tolerances requires specialized knowledge, including the use of very sharp tools, moderate cutting speeds to prevent overheating, and careful clamping to avoid deforming the part.

When to Specify PTFE Etching

Applying this knowledge correctly depends entirely on your end goal.

- If your primary focus is creating a composite part: Specify etching on the side of the PTFE that will be bonded to another substrate, like a metal backing or composite laminate.

- If your primary focus is applying a coating or paint: Etching is an essential pre-treatment to ensure the coating will adhere permanently to the PTFE surface.

- If your primary focus is a standalone, low-friction component: Etching is unnecessary and counterproductive, as it eliminates the non-stick property you need.

Understanding when and how to modify PTFE's surface is the key to leveraging its unique properties without being limited by them.

Summary Table:

| Aspect | Before Etching | After Etching |

|---|---|---|

| Surface Chemistry | Inert, high fluorine content | Active, carbon-rich layer |

| Appearance | White, slick | Dark brown, matte |

| Bondability | Non-stick, cannot be glued | Receptive to adhesives & coatings |

| Primary Use Case | Standalone low-friction parts | Bonded liners, composite assemblies |

Need precision-etched PTFE components for your semiconductor, medical, or laboratory application?

KINTEK specializes in the custom fabrication of high-performance PTFE components, including precision etching to solve your toughest bonding challenges. From prototypes to high-volume orders, we ensure your parts meet exact specifications for reliability and performance.

Contact our experts today to discuss how our etched PTFE solutions can enhance your product assembly.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments