In the high-stakes environment of a laboratory, PTFE bearings offer a unique combination of benefits that directly address the core requirements of scientific work. They provide exceptional chemical inertness, self-lubricating properties, and thermal stability, ensuring that precision instruments like stirrers, pumps, and valves operate reliably without contaminating sensitive substances or failing due to corrosive reagents.

The fundamental value of a PTFE bearing in a laboratory setting is its ability to be functionally invisible. Its defining chemical inertness ensures the bearing never becomes an uncontrolled variable in an experiment, thereby protecting data integrity and preserving equipment life.

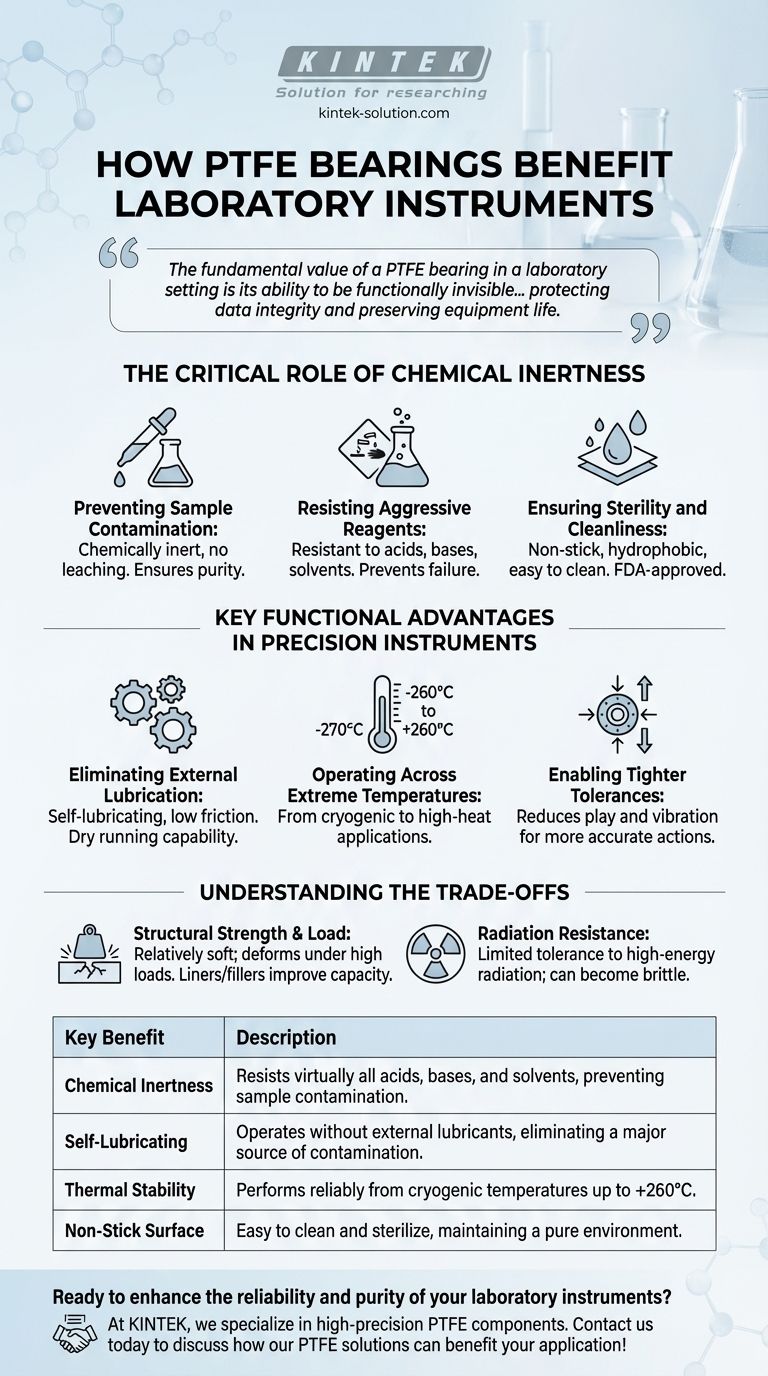

The Critical Role of Chemical Inertness

In laboratory analysis, any component that contacts a sample or reagent can become a source of contamination. The material properties of PTFE bearings directly mitigate this risk, ensuring the purity of the work.

Preventing Sample Contamination

PTFE is chemically inert, meaning it does not react with or leach substances into its environment. This is critical in equipment like mixers, pumps, or auto-samplers where the bearing may be in close proximity to sensitive chemicals.

This property ensures that the results of an experiment reflect the sample, not a contaminant introduced by the equipment itself.

Resisting Aggressive Reagents

Laboratory instruments are frequently exposed to a wide range of corrosive acids, bases, and solvents. PTFE is resistant to nearly all of these chemicals.

This ensures the bearing maintains its structural integrity and functional performance over its entire lifespan, preventing premature equipment failure. PTFE-lined containers and components are often used specifically for storing and handling the most corrosive substances safely.

Ensuring Sterility and Cleanliness

PTFE has a non-stick, hydrophobic (water-repelling) surface, which makes it inherently difficult for biological or chemical materials to adhere to it.

This characteristic, combined with its ability to withstand harsh cleaning agents, makes it easy to maintain a sterile environment. The material is also frequently FDA-approved for food and medical contact, underscoring its purity.

Key Functional Advantages in Precision Instruments

Beyond its chemical properties, PTFE provides mechanical benefits that are essential for the smooth and reliable operation of sensitive laboratory equipment.

Eliminating External Lubrication

PTFE is a self-lubricating material with an extremely low coefficient of friction. This eliminates the need for external greases or oils, which are major sources of contamination in a clean lab environment.

This "dry running" capability ensures that mechanical motion is smooth and consistent without introducing foreign substances into the system.

Operating Across Extreme Temperatures

Many laboratory procedures involve extreme heating or cooling. PTFE maintains its properties across an exceptionally wide temperature range, typically from -270°C to +260°C (-454°F to +500°F).

This thermal stability allows PTFE bearings to function reliably in equipment used for cryogenics, high-temperature chemical synthesis, or thermal cycling.

Enabling Tighter Tolerances

Because PTFE liners do not require significant clearance for lubricants, they can be manufactured with tighter fits between moving parts.

This reduces play and vibration in precision instruments, leading to more accurate and repeatable mechanical actions, which is vital for robotics and automated analytical systems.

Understanding the Trade-offs

While PTFE is an exceptional material, no single solution is perfect for every application. Understanding its limitations is key to making an informed decision.

Structural Strength and Load Capacity

Pure PTFE is a relatively soft material. While it has high flexural strength, it can deform under very high static loads or in high-impact applications.

For high-load scenarios, PTFE is often used as a liner within a more rigid metallic shell or blended with reinforcing fillers to improve its wear resistance and load-bearing capacity.

Radiation Resistance

While PTFE has good resistance to UV rays and oxidation, its tolerance for high-energy radiation is limited.

In applications involving significant levels of radiation, the material can become brittle over time. This is a critical consideration for equipment used in nuclear research or certain sterilization processes.

Making the Right Choice for Your Goal

To select the appropriate bearing, align the material's strengths with the primary demand of the application.

- If your primary focus is analytical purity and preventing sample contamination: PTFE is the definitive choice due to its unmatched chemical inertness.

- If your primary focus is consistent mechanical performance without lubricants: The self-lubricating and low-friction properties of PTFE ensure smooth, clean operation.

- If your primary focus is equipment longevity in a corrosive environment: PTFE's broad chemical resistance will protect the bearing and the instrument from degradation.

Ultimately, choosing PTFE bearings is a strategic decision to remove the component itself as a potential source of experimental error or operational failure.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents, preventing sample contamination. |

| Self-Lubricating | Operates without external lubricants, eliminating a major source of contamination. |

| Thermal Stability | Performs reliably from cryogenic temperatures up to +260°C. |

| Non-Stick Surface | Easy to clean and sterilize, maintaining a pure environment. |

Ready to enhance the reliability and purity of your laboratory instruments?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates with the utmost integrity, free from contamination.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific needs.

Contact us today to discuss how our PTFE solutions can benefit your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance