In short, the primary performance advantages of PTFE as a gasketing material are its near-universal chemical resistance and its exceptionally wide operating temperature range. This combination makes it a highly reliable sealing solution for the most demanding chemical, pharmaceutical, and food processing applications where other materials would quickly fail.

Polytetrafluoroethylene (PTFE) is the default choice for sealing applications involving aggressive chemicals or requiring high purity. Its core value lies in its chemical inertness, but success depends on selecting the correct form of PTFE to manage its inherent mechanical limitations.

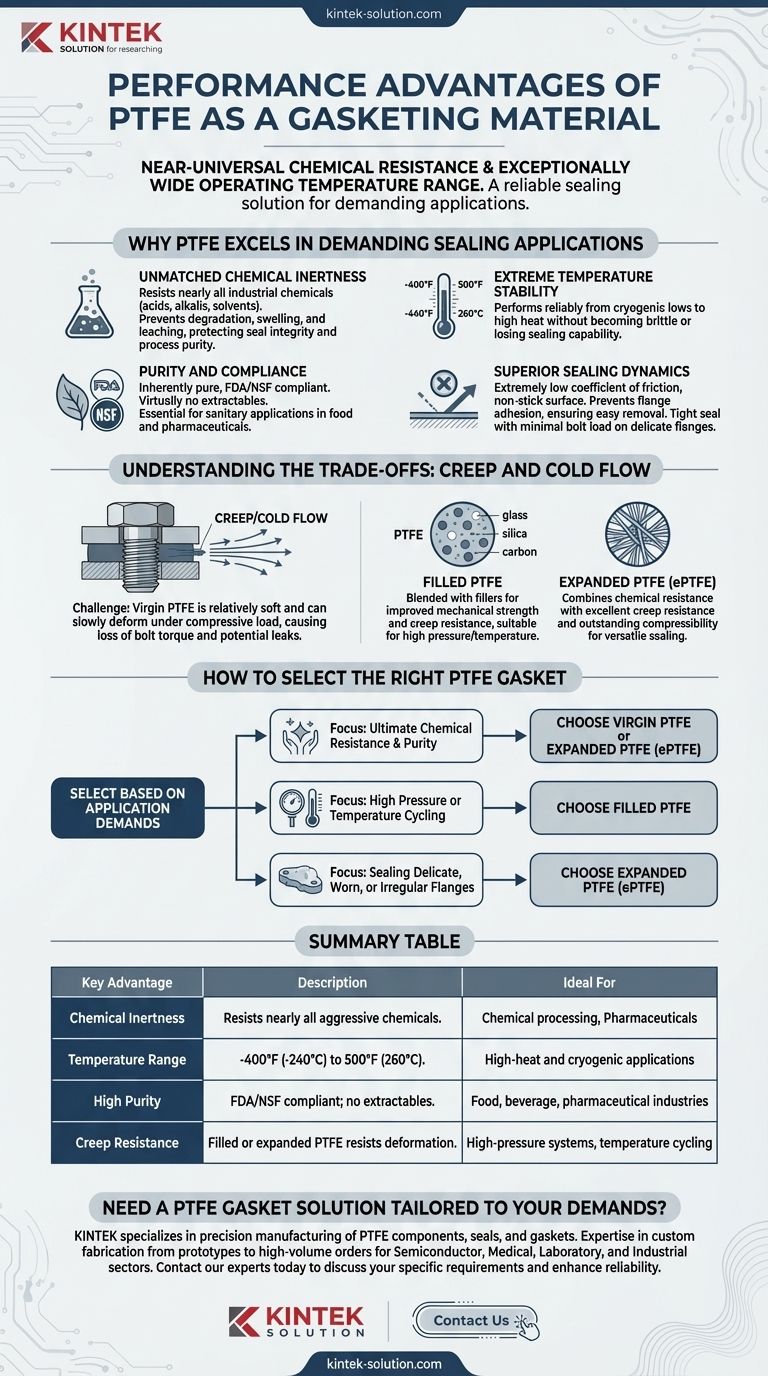

Why PTFE Excels in Demanding Sealing Applications

PTFE, often recognized by the brand name Teflon, is a fluoropolymer with a unique set of properties. These characteristics make it a premier material for creating a reliable seal under challenging operational conditions.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including the most aggressive acids, alkalis, and solvents.

This exceptional resistance prevents the gasket from degrading, swelling, or leaching contaminants, which protects both the integrity of the seal and the purity of the process medium.

Extreme Temperature Stability

PTFE gaskets perform reliably across a vast temperature spectrum, typically from cryogenic lows of -400°F (-240°C) up to highs of 500°F (260°C).

This stability allows it to be specified in systems that handle extreme cold or high-heat processes without becoming brittle or losing its sealing capability.

Purity and Compliance

Standard PTFE is inherently pure and can comply with FDA and NSF standards for contact with food and pharmaceuticals.

It has virtually no extractables, meaning it won't shed material into the process stream. This biocompatibility makes it essential for sanitary applications where contamination is not an option.

Superior Sealing Dynamics

PTFE has an extremely low coefficient of friction, creating a non-stick surface. This property prevents the gasket from adhering to flange surfaces, ensuring easy removal without damaging expensive equipment.

Furthermore, certain forms of PTFE can create a tight seal with minimal bolt load, making them ideal for use on delicate or irregular flanges, such as glass-lined or plastic piping.

Understanding the Trade-offs: Creep and Cold Flow

While its chemical and thermal properties are elite, it is critical to understand the primary mechanical limitation of PTFE.

The Challenge of "Creep"

Virgin, or unfilled, PTFE is a relatively soft material. When placed under the compressive load of a bolted flange, it can slowly deform over time.

This phenomenon, known as creep or cold flow, causes a loss of bolt torque. This reduction in sealing stress can eventually lead to leaks, particularly in applications with pressure or temperature cycles.

The Solution: Filled and Expanded PTFE

To counteract creep, standard PTFE is often blended with filler materials like glass, silica, or carbon. This filled PTFE offers significantly improved mechanical strength and creep resistance, making it suitable for higher pressure and temperature services.

Another advanced solution is expanded PTFE (ePTFE), which has a multi-directional fibrous structure. This material combines the chemical resistance of virgin PTFE with excellent creep resistance and outstanding compressibility, making it one of the most versatile sealing materials available.

How to Select the Right PTFE Gasket

Choosing the correct type of PTFE gasket is essential for ensuring a safe and reliable seal. Your decision should be based on the specific demands of your application.

- If your primary focus is ultimate chemical resistance and purity: Choose a virgin PTFE or expanded PTFE (ePTFE) gasket, as these contain no fillers that could potentially react with or contaminate the process media.

- If your primary focus is managing high pressure or temperature cycling: Choose a filled PTFE gasket designed to resist creep and maintain stable bolt load under demanding mechanical conditions.

- If your primary focus is sealing delicate, worn, or irregular flanges: Choose an expanded PTFE (ePTFE) gasket, as its high compressibility allows it to conform to surface imperfections with minimal compressive force.

Ultimately, selecting the right PTFE material is about matching its unique properties to the precise chemical and mechanical stresses of your system.

Summary Table:

| Key Advantage | Description | Ideal For |

|---|---|---|

| Chemical Inertness | Resists nearly all aggressive acids, alkalis, and solvents. | Chemical processing, pharmaceuticals. |

| Temperature Range | Performs from -400°F (-240°C) to 500°F (260°C). | High-heat and cryogenic applications. |

| High Purity | FDA/NSF compliant; no extractables for sanitary processes. | Food, beverage, and pharmaceutical industries. |

| Creep Resistance | Filled or expanded PTFE versions resist deformation under load. | High-pressure systems and temperature cycling. |

Need a PTFE Gasket Solution Tailored to Your Demands?

KINTEK specializes in the precision manufacturing of PTFE components, including seals, gaskets, liners, and custom labware. Whether your application requires ultimate chemical purity for a pharmaceutical process, high creep resistance for a demanding industrial system, or a custom prototype, our expertise ensures a reliable and high-performance solution.

We serve: Semiconductor, Medical, Laboratory, Industrial, and other specialized industries.

We deliver: Custom fabrication from prototypes to high-volume orders, with a focus on precision and quality.

Contact our experts today to discuss your specific requirements and discover how KINTEK can enhance the reliability and performance of your sealing applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability