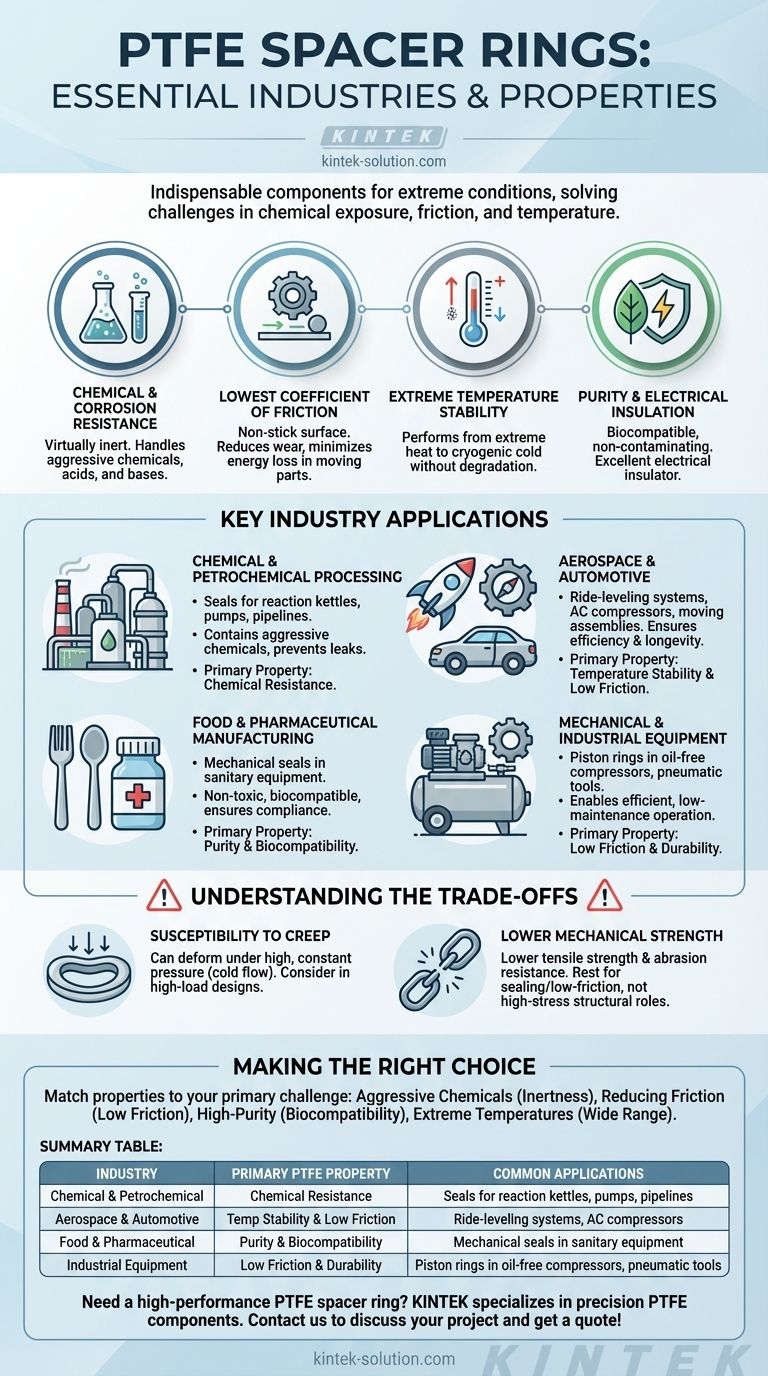

At a high level, PTFE spacer rings are indispensable components in industries where extreme conditions are the norm, including mechanical engineering, aerospace, chemical processing, automotive, and food and pharmaceutical manufacturing. Their adoption is driven by a unique set of material properties that solve critical engineering challenges related to chemical exposure, friction, and temperature.

The widespread use of PTFE spacer rings is not based on a single feature, but on a powerful combination of chemical inertness, an extremely low coefficient of friction, and a wide operating temperature range. This makes PTFE a versatile problem-solver for the most demanding industrial environments.

Why PTFE is the Material of Choice for Critical Applications

The value of PTFE (Polytetrafluoroethylene) in industrial applications stems directly from its core material science. Understanding these properties explains why it's so widely adopted.

Unmatched Chemical and Corrosion Resistance

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, acids, and bases. This makes it an essential material for equipment that handles aggressive or corrosive substances.

The Lowest Coefficient of Friction

Known for its non-stick surface, PTFE has one of the lowest coefficients of friction of any solid material. This property is critical for reducing wear, minimizing energy loss, and ensuring smooth operation in moving parts like pistons and seals.

Extreme Temperature Stability

PTFE maintains its integrity and performance across a very broad temperature range. It can withstand extreme heat and cryogenic cold without becoming brittle or degrading, a crucial trait for aerospace and heavy industrial machinery.

Purity and Electrical Insulation

PTFE is inherently pure, biocompatible, and does not contaminate the materials it contacts. It is also an excellent electrical insulator, preventing unwanted electrical discharge in sensitive equipment.

Key Industry Applications in Detail

The theoretical properties of PTFE translate into tangible advantages across several key sectors. Each industry leverages specific characteristics to solve its unique challenges.

In Chemical and Petrochemical Processing

The primary driver here is chemical resistance. PTFE spacer rings are used in seals for reaction kettles, storage tanks, pumps, and pipelines to safely contain aggressive chemicals and prevent costly, hazardous leaks.

In Aerospace and Automotive

In these sectors, temperature stability and low friction are paramount. PTFE components are used in systems exposed to high temperatures and in parts like ride-leveling systems, air-conditioning compressors, and other moving assemblies where reducing friction is key to efficiency and longevity.

In Food and Pharmaceutical Manufacturing

Purity and chemical inertness are non-negotiable. PTFE is used for mechanical seals and spacers because it is non-toxic, biocompatible, and will not contaminate products, ensuring compliance with strict health and safety standards.

In Mechanical and Industrial Equipment

This broad category leverages PTFE's low friction and durability. It is a standard material for piston rings in oil-free compressors, gas rotary pumps, and pneumatic tools, where it enables efficient operation with minimal lubrication and maintenance.

Understanding the Trade-offs

While incredibly versatile, PTFE is not the solution for every engineering problem. Its limitations are important to consider for proper application.

Susceptibility to Creep

Under high, constant pressure, PTFE can be subject to "creep" or cold flow, where the material slowly deforms over time. This must be accounted for in high-load structural designs.

Lower Mechanical Strength

Compared to metals or other high-performance polymers, PTFE has lower tensile strength and abrasion resistance. It is best suited for sealing and low-friction applications rather than high-stress structural roles.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is handling aggressive chemicals: PTFE's unparalleled inertness makes it the default choice for seals and spacers in chemical processing.

- If your primary focus is reducing friction in moving parts: Its remarkably low coefficient of friction is ideal for enhancing the efficiency of compressors, pumps, and automotive components.

- If your primary focus is high-purity or sanitary applications: PTFE's biocompatibility and non-contaminating nature are essential for the food, pharmaceutical, and medical industries.

- If your primary focus is performance in extreme temperatures: Its wide operating range makes it a reliable solution for aerospace and demanding industrial machinery.

By matching the distinct properties of PTFE to your specific operational demands, you can ensure optimal performance and reliability in your equipment.

Summary Table:

| Industry | Primary PTFE Property Utilized | Common Applications |

|---|---|---|

| Chemical & Petrochemical | Chemical Resistance | Seals for reaction kettles, pumps, pipelines |

| Aerospace & Automotive | Temperature Stability & Low Friction | Ride-leveling systems, AC compressors |

| Food & Pharmaceutical | Purity & Biocompatibility | Mechanical seals in sanitary equipment |

| Industrial Equipment | Low Friction & Durability | Piston rings in oil-free compressors, pneumatic tools |

Need a high-performance PTFE spacer ring for your specific application?

KINTEK specializes in manufacturing precision PTFE components—including custom spacer rings, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine expert material knowledge with custom fabrication capabilities, from prototypes to high-volume orders, to deliver a solution that meets your exact requirements for chemical resistance, temperature stability, and low friction.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments