Expanded PTFE (ePTFE) is a cornerstone material for sealing applications in industries where failure is not an option. It is most commonly specified in chemical processing, pharmaceuticals, and food and beverage manufacturing due to its unique combination of chemical inertness and sealing performance. Its use also extends to other demanding sectors like aerospace, electronics, and energy production.

The critical insight is that ePTFE is chosen not just for its ability to create a seal, but for what it doesn't do: it doesn't react with aggressive chemicals, it doesn't contaminate pure products, and it doesn't degrade under harsh conditions. This makes it the default choice for applications where purity, safety, and reliability are paramount.

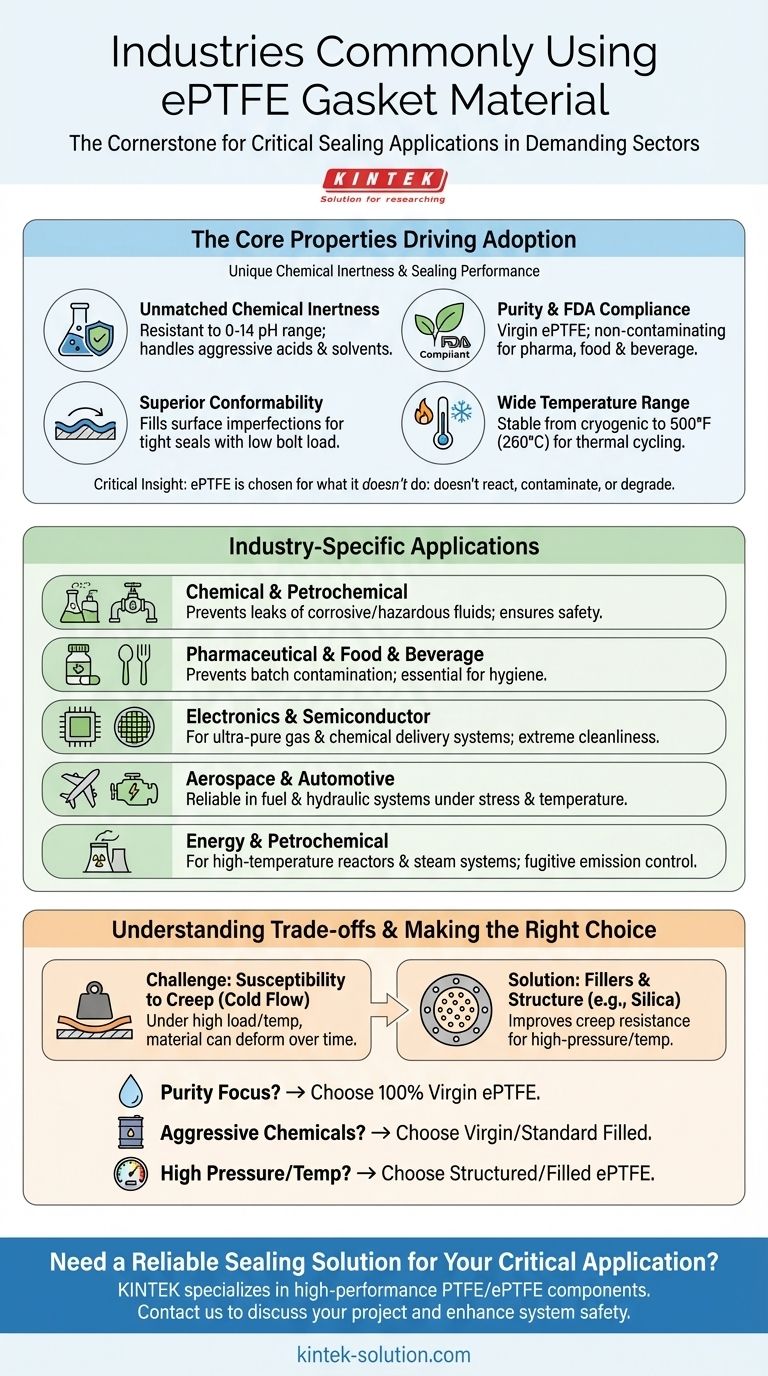

The Core Properties Driving ePTFE Adoption

The widespread use of ePTFE is not accidental. It is a direct result of several key material properties that solve critical industrial challenges.

Unmatched Chemical Inertness

ePTFE is resistant to virtually all chemicals across the entire 0-14 pH range. The only exceptions are molten alkali metals and elemental fluorine.

This property makes it indispensable in the chemical processing industry for sealing flanges that handle aggressive acids, solvents, and bases without being degraded or compromising the process media.

Purity and FDA Compliance

Virgin ePTFE is an inherently pure material that does not contaminate the media it contacts. It contains no binders or additives that could leach into a product.

This is why it is heavily used in pharmaceutical and food & beverage manufacturing. The material often complies with FDA regulations for food contact, ensuring product purity and consumer safety in sanitary applications.

Superior Conformability and Sealing

The "expanded" structure of ePTFE creates a soft, highly conformable material. It can effectively fill in surface imperfections on worn, pitted, or uneven flange surfaces.

This creates an extremely tight seal with low bolt load, significantly reducing the potential for fugitive emissions and leaks. This is a crucial benefit for any industry, but especially those handling hazardous materials.

Wide Temperature Range

ePTFE maintains its integrity and sealing capabilities across a broad temperature spectrum, typically from cryogenic temperatures up to 500°F (260°C).

This thermal stability makes it suitable for applications involving steam-in-place (SIP) cycles, chemical reactors, and systems with significant temperature fluctuations found in the energy and petrochemical sectors.

Industry-Specific Applications

While the core properties are universal, their value is realized in different ways across various industries.

Chemical and Petrochemical

In this sector, ePTFE gaskets are used in pipelines, reactors, and valve bonnets to prevent leaks of corrosive or hazardous fluids. Its reliability ensures plant safety and environmental compliance.

Pharmaceutical and Food & Beverage

The primary goal here is preventing batch contamination. ePTFE's purity is essential for sealing mixing tanks, piping systems, and processing equipment where hygiene and non-reactivity are non-negotiable.

Electronics and Semiconductor

Manufacturing microchips involves ultra-pure gases and aggressive cleaning agents. ePTFE gaskets are used to seal delivery systems and process chambers, ensuring the extreme cleanliness required for semiconductor fabrication.

Aerospace and Automotive

In these industries, reliability is paramount. ePTFE seals are used in fuel systems, hydraulic lines, and other critical fluid transfer applications where performance under stress and extreme temperatures is essential for safe operation.

Understanding the Trade-offs and Considerations

While ePTFE is a high-performance material, it is crucial to understand its limitations to specify it correctly.

Susceptibility to Creep

The primary trade-off for ePTFE's excellent conformability is its tendency to "creep," or cold flow. Under high bolt loads and temperatures, the material can slowly deform, leading to a loss of bolt torque and sealing stress over time.

The Role of Fillers and Structure

To combat creep, many ePTFE gaskets are manufactured with fillers (like silica or barium sulfate) or are engineered with a rigid internal structure.

These modifications significantly improve creep resistance and make the gasket suitable for high-pressure and high-temperature applications. However, adding fillers can slightly diminish the gasket's universal chemical resistance, creating a necessary trade-off between mechanical stability and chemical inertness.

Cost vs. Performance

ePTFE is a premium gasket material. Its cost is higher than that of standard elastomeric or fiber gaskets. This cost is justified by superior performance, reduced downtime, enhanced safety, and protection of high-value products. For non-critical, low-temperature water lines, it may be an unnecessary expense.

Making the Right Choice for Your Goal

Your specific application dictates the best choice of gasket material.

- If your primary focus is purity and compliance: Choose a 100% virgin ePTFE gasket for its non-contaminating properties, especially in food, beverage, and pharmaceutical lines.

- If your primary focus is sealing aggressive chemicals in standard flanges: A virgin or standard filled ePTFE gasket is an excellent choice for its near-universal chemical resistance and reliable sealability.

- If your primary focus is handling high pressure, thermal cycling, or sealing damaged flanges: Select a structured or filled ePTFE designed for superior creep resistance to ensure a durable, long-lasting seal.

Understanding these properties allows you to move beyond simply choosing a material and instead select a strategic solution for ensuring your system's operational integrity.

Summary Table:

| Industry | Key ePTFE Application | Primary Benefit |

|---|---|---|

| Chemical Processing | Sealing flanges with aggressive acids/bases | Chemical inertness, leak prevention |

| Pharmaceutical & Food/Beverage | Sanitary piping, mixing tanks | Purity, FDA compliance, non-contamination |

| Electronics/Semiconductor | Ultra-pure gas and chemical delivery systems | Extreme cleanliness, reliability |

| Aerospace & Automotive | Fuel and hydraulic systems | Performance under stress and temperature extremes |

| Energy & Petrochemical | High-temperature reactors, steam systems | Thermal stability, fugitive emission control |

Need a reliable sealing solution for your critical application? KINTEK specializes in manufacturing high-performance PTFE and ePTFE components—including custom gaskets, seals, liners, and labware—for semiconductor, medical, laboratory, and industrial sectors. We ensure precision production, from prototypes to high-volume orders, to meet your exact requirements for purity, chemical resistance, and durability.

Contact us today to discuss your project and discover how our expertise can enhance your system's safety and performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Can PTFE envelope gaskets be customized? Tailor the Perfect Seal for Your Application

- What are the key roles of gland packing in industrial applications? Achieve Robust, Controllable Sealing

- What are the characteristics of unidirectional PTFE lip seals? Superior One-Way Sealing for Demanding Applications

- What are the advantages of using PTFE Expansion Bellows? Maximize System Integrity & Uptime

- What is FEP and how does it differ from PTFE? Key Differences in Performance & Manufacturing

- What materials are commonly used to fortify PTFE seals? Enhance Performance with Glass, Carbon, Graphite & Bronze

- What are the core material options for PTFE encapsulated O-rings? Choose Viton® or Silicone for Your Sealing Needs

- What are the key properties of EPTFE gaskets? Superior Sealing for Extreme Conditions