The key properties of ePTFE gaskets are their exceptional chemical inertness, a wide operational temperature range, and a unique mechanical ability to conform to irregular surfaces while resisting the creep and cold flow that plague standard PTFE materials. This combination makes ePTFE a premier choice for demanding industrial sealing applications where reliability is paramount.

ePTFE (expanded Polytetrafluoroethylene) is not simply a material; it is a microstructured solution. It solves the most difficult sealing challenges by combining the chemical immunity of PTFE with the mechanical resilience needed for real-world, imperfect flange conditions.

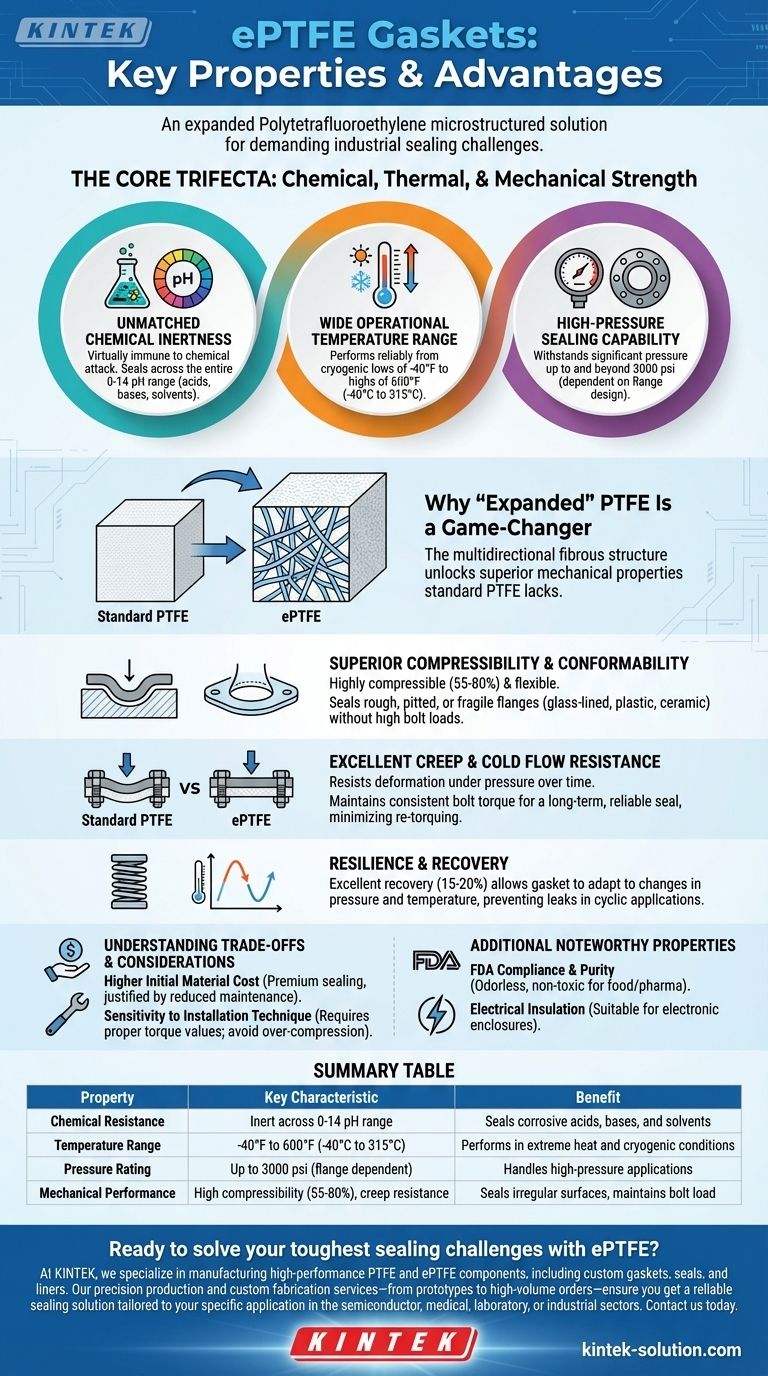

The Core Trifecta: Chemical, Thermal, and Mechanical Strength

Understanding ePTFE begins with its three primary advantages. These properties work in concert to create a seal that is both robust and remarkably versatile.

Unmatched Chemical Inertness

An ePTFE gasket is virtually immune to chemical attack. It can safely seal media across the entire 0-14 pH range, from highly corrosive acids to caustic bases.

This resistance covers a vast spectrum of industrial substances, including solvents, oils, petroleum hydrocarbons, and alkalis. The only common exceptions are molten alkali metals and free fluorine atoms.

Wide Operational Temperature Range

ePTFE performs reliably across extreme temperatures. It maintains its integrity and sealing capability in applications ranging from cryogenic lows of -40°F up to highs of 600°F (-40°C to 315°C).

This thermal stability makes it suitable for processes involving significant temperature fluctuations, where other materials might become brittle or degrade.

High-Pressure Sealing Capability

When properly installed in an appropriate flange, ePTFE gaskets can withstand significant pressure. They are often rated for service in applications up to and beyond 3000 psi.

It is critical to note that maximum pressure rating is heavily dependent on the specific flange design, media, and temperature.

Why "Expanded" PTFE Is a Game-Changer

The "expansion" process creates a multidirectional fibrous structure within the PTFE, unlocking mechanical properties that standard PTFE cannot match. This structure is the key to its superior performance as a gasket material.

Superior Compressibility and Conformability

ePTFE is highly compressible and flexible, allowing it to flow into and seal rough, pitted, or irregular flange surfaces where more rigid gaskets would fail.

With a compression ratio between 55% and 80%, it is an ideal solution for protecting fragile equipment, such as glass-lined steel, plastic, or ceramic flanges that cannot withstand high bolt loads.

Excellent Creep and Cold Flow Resistance

One of the most significant advantages of ePTFE is its resistance to creep and cold flow. Unlike standard PTFE, which can deform and loosen under pressure over time, ePTFE maintains its shape.

This property ensures the bolt torque remains consistent, creating a highly reliable, long-term seal that minimizes the need for re-torquing.

Resilience and Recovery

The fibrous structure gives ePTFE excellent recovery properties. It has a rebound rate of 15% to 20%, allowing the gasket to adapt to changes in pressure and temperature.

This resilience is crucial in applications with thermal cycling or variable loads, as the gasket can expand and contract with the flange, preventing leaks.

Understanding the Trade-offs and Considerations

While ePTFE is a high-performance material, no solution is perfect for every scenario. An objective assessment requires acknowledging its limitations.

Higher Initial Material Cost

ePTFE is a premium sealing material. Its initial cost is typically higher than that of standard compressed fiber gaskets or common elastomers. However, this cost is often justified by reduced maintenance and increased operational uptime in critical applications.

Sensitivity to Installation Technique

To leverage its full potential, ePTFE requires proper installation. Over-compression can crush the material's unique fibrous structure, compromising its long-term sealing ability and creep resistance. Following manufacturer-specified torque values is essential for success.

Additional Noteworthy Properties

Beyond its primary functions, ePTFE possesses other valuable characteristics.

FDA Compliance and Purity

Many grades of ePTFE meet stringent FDA and USP Class VI standards. Being odorless and non-toxic, it is an excellent choice for sealing applications in the food, beverage, and pharmaceutical industries where purity is non-negotiable.

Electrical Insulation

Like standard PTFE, ePTFE has excellent electrical insulation properties. This makes it a suitable material for sealing enclosures on sensitive electronic components and circuit boards.

Making the Right Choice for Your Goal

Selecting ePTFE should be a decision based on the specific demands of your application.

- If your primary focus is aggressive chemical service: ePTFE is a top-tier choice due to its near-total chemical inertness across the full pH range.

- If you are dealing with fragile or uneven flanges: The high compressibility of ePTFE allows it to create a reliable seal where rigid gaskets would fail.

- If your application involves thermal cycling or variable loads: ePTFE's resistance to creep and its excellent recovery properties ensure a long-lasting, dependable seal.

- If you are managing a low-pressure, non-critical system: You may want to evaluate less expensive alternatives, as ePTFE is engineered for high-performance demands.

Ultimately, choosing ePTFE is an investment in long-term reliability for your most critical sealing challenges.

Summary Table:

| Property | Key Characteristic | Benefit |

|---|---|---|

| Chemical Resistance | Inert across 0-14 pH range | Seals corrosive acids, bases, and solvents |

| Temperature Range | -40°F to 600°F (-40°C to 315°C) | Performs in extreme heat and cryogenic conditions |

| Pressure Rating | Up to 3000 psi (flange dependent) | Handles high-pressure applications |

| Mechanical Performance | High compressibility (55-80%), creep resistance | Seals irregular surfaces, maintains bolt load |

Ready to solve your toughest sealing challenges with ePTFE?

At KINTEK, we specialize in manufacturing high-performance PTFE and ePTFE components, including custom gaskets, seals, and liners. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a reliable sealing solution tailored to your specific application in the semiconductor, medical, laboratory, or industrial sectors.

Contact us today to discuss how our ePTFE gaskets can enhance the reliability and longevity of your equipment. Get in touch via our contact form for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers