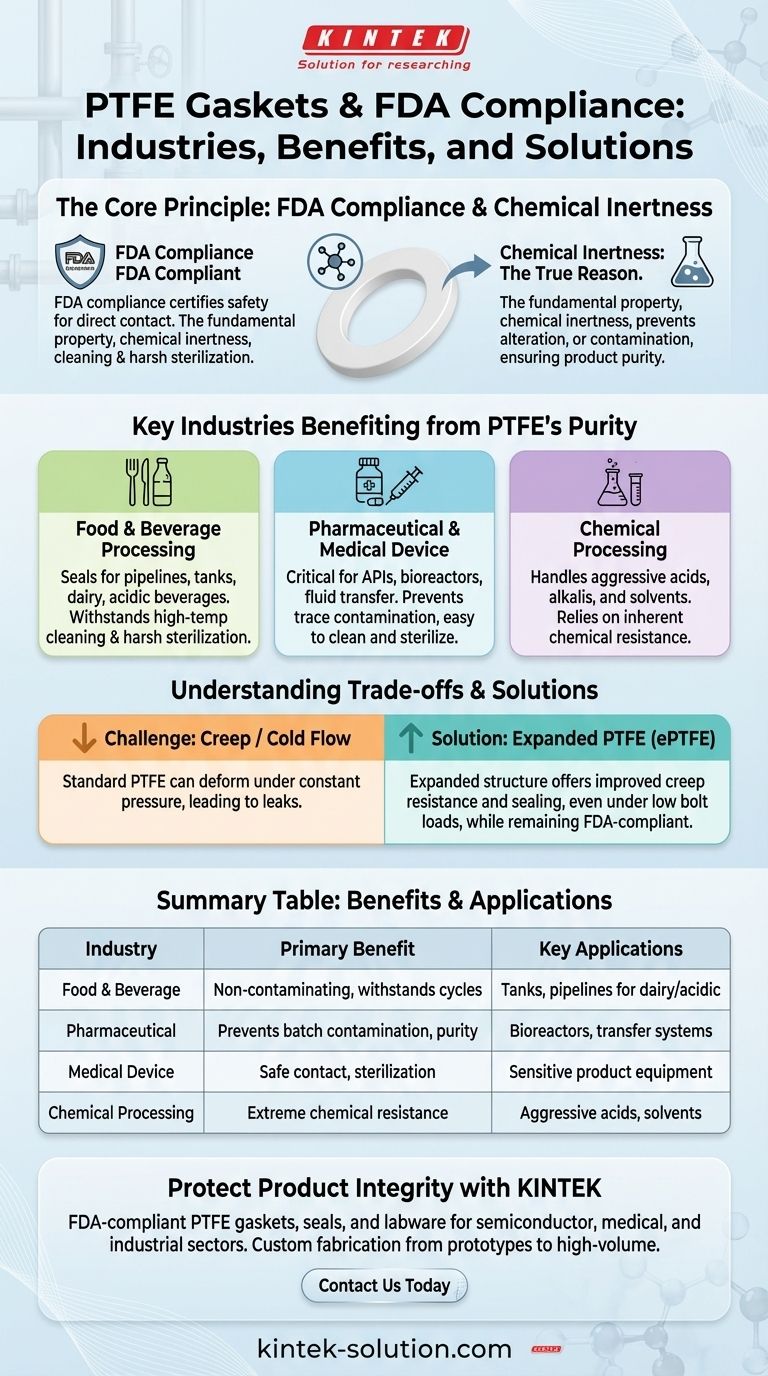

Most notably, the food and beverage, pharmaceutical, and medical device manufacturing industries benefit directly from PTFE gaskets due to their FDA compliance. This compliance certifies that the material is safe for direct contact with consumables and medical products, ensuring it will not leach harmful substances or contaminate the final product.

While FDA compliance is the formal requirement, the true reason these industries rely on PTFE is its fundamental chemical inertness. This inherent property is what allows PTFE to pass FDA standards, as it does not react with, alter, or contaminate the sensitive products it seals.

The Core Principle: Why FDA Compliance Matters

For a gasket material to be used in sensitive applications, it must not compromise the integrity of the product. FDA compliance is the benchmark for this safety.

Defining FDA Compliance in Gaskets

FDA (U.S. Food and Drug Administration) compliance for a material like Polytetrafluoroethylene (PTFE) means it is considered "food-grade." The material is non-toxic and safe for direct contact with food, beverages, and pharmaceutical ingredients.

This certification ensures the gasket itself does not become a source of contamination.

Beyond Compliance: The Role of Chemical Inertness

The foundational property that makes PTFE suitable for these applications is its extreme chemical inertness. PTFE is resistant to nearly all chemicals, acids, and solvents.

This means the gasket will not react with the product it is sealing, preventing any alteration of flavor, odor, or chemical composition. It guarantees product purity.

Ensuring Cleanliness and Preventing Contamination

In pharmaceutical and food processing, hygiene is paramount. PTFE's smooth, non-porous surface resists the buildup of bacteria and is easy to clean and sterilize.

This non-corrosive and non-reactive nature ensures that the gasket material itself does not degrade, shed particles, or leach chemicals into the processing line.

Key Industries Benefiting from PTFE's Properties

While many sectors use PTFE for its durability, a few rely on its purity and compliance as a non-negotiable requirement.

Food and Beverage Processing

This is the most common application for FDA-compliant PTFE. Gaskets are used to seal pipelines, tanks, and processing equipment that handle everything from dairy products to acidic beverages.

The material must withstand not only the product itself but also high-temperature cleaning cycles and harsh sterilization agents, which PTFE handles exceptionally well.

Pharmaceutical and Medical Device Manufacturing

In this industry, even trace amounts of contamination can render an entire batch of medicine unusable or unsafe. PTFE's purity is critical.

It is used to seal vessels, bioreactors, and fluid transfer systems where it contacts active pharmaceutical ingredients (APIs) and other sensitive compounds without any risk of reaction.

Chemical Processing

While not always driven by FDA rules, the chemical processing industry relies on the same core property: chemical resistance.

PTFE gaskets are used to handle aggressive acids, alkalis, and solvents that would destroy other sealing materials. This demonstrates the material's inherent robustness, which underpins its value in food and pharma.

Understanding the Trade-offs of PTFE Gaskets

No material is perfect. Acknowledging PTFE's limitations is key to using it effectively and avoiding seal failure.

The Challenge of Creep and Cold Flow

Standard, unmodified PTFE can be susceptible to creep, or "cold flow." This is the tendency for the material to slowly deform and expand outward over time when under constant pressure (like a tightened flange).

This can lead to a loss of bolt torque and potential leaks, especially in applications with fluctuating temperatures or pressures.

The Solution: Filled and Expanded PTFE

To counteract creep, manufacturers have developed enhanced versions of PTFE. Filled PTFE includes additives like glass or carbon to improve mechanical strength and reduce deformation.

Expanded PTFE (ePTFE) has a multi-directional fibrous structure that provides the chemical resistance of PTFE with dramatically improved creep resistance and sealing performance, even under low bolt loads. It is also FDA-compliant and widely used in sensitive industries.

Making the Right Choice for Your Application

Selecting the correct gasket material requires matching its properties to the specific demands of your system.

- If your primary focus is product purity and FDA compliance: Virgin PTFE or expanded PTFE are definitive choices due to their unparalleled chemical inertness and non-contaminating properties.

- If you need to manage high pressure or temperature fluctuations alongside compliance: Expanded PTFE (ePTFE) is the superior option as it provides excellent sealability and resists the creep that can affect standard PTFE.

- If your application involves aggressive chemicals outside of food/pharma: The exceptional chemical resistance of any PTFE variant makes it a top contender, but always verify its suitability against your specific chemical agents and operating conditions.

Ultimately, choosing an FDA-compliant PTFE gasket is a decision that protects both the integrity of your product and the reliability of your process.

Summary Table:

| Industry | Primary Benefit of PTFE Gaskets | Key Application Examples |

|---|---|---|

| Food & Beverage | Non-contaminating, withstands cleaning cycles | Sealing tanks, pipelines for dairy, acidic drinks |

| Pharmaceutical | Prevents batch contamination, ensures purity | Sealing bioreactors, fluid transfer systems |

| Medical Device | Safe contact, easy sterilization | Sealing equipment for sensitive medical products |

| Chemical Processing | Extreme chemical resistance | Handling aggressive acids, solvents, alkalis |

Protect your product integrity with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our FDA-compliant PTFE gaskets, seals, liners, and labware are manufactured to the highest standards of purity and performance. We specialize in custom fabrication—from prototypes to high-volume orders—ensuring a perfect fit for your unique application needs.

Contact us today to discuss how our PTFE solutions can enhance your process safety and reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why are gaskets made of Teflon used in construction? Prevent Galvanic Corrosion Between Dissimilar Metals

- What factors should be considered when selecting a PTFE-lined valve? Ensure Long-Term Reliability & Safety

- Why are PTFE gaskets preferred in high-temperature environments? Ensure Reliable Sealing Under Extreme Heat

- What are the limitations of PTFE when used as a mechanical component? Overcoming Softness & Instability

- How do PTFE rotary shaft lip seals benefit the food processing industry? Ensure Hygiene & Reliability

- What factors should be considered when choosing between PTFE and EPDM valve seats? Ensure Reliable Fluid Control

- What are the components of Teflon encapsulated O-rings? A Guide to Their Dual-Material Design

- Why are PTFE O-rings non-stick? Unlock the Molecular Secret to Frictionless Sealing