In construction, Teflon (PTFE) gaskets are used for one primary, critical reason: to prevent galvanic corrosion by electrically isolating dissimilar metals when they are joined together. While they also provide sealing, their main function in structural and piping applications is to act as a non-conductive barrier, stopping a destructive electrochemical reaction that can compromise the integrity of a connection.

The decision to use a Teflon gasket is not merely about sealing a joint; it is a crucial engineering control to prevent the premature and often hidden failure of connections between different types of metal.

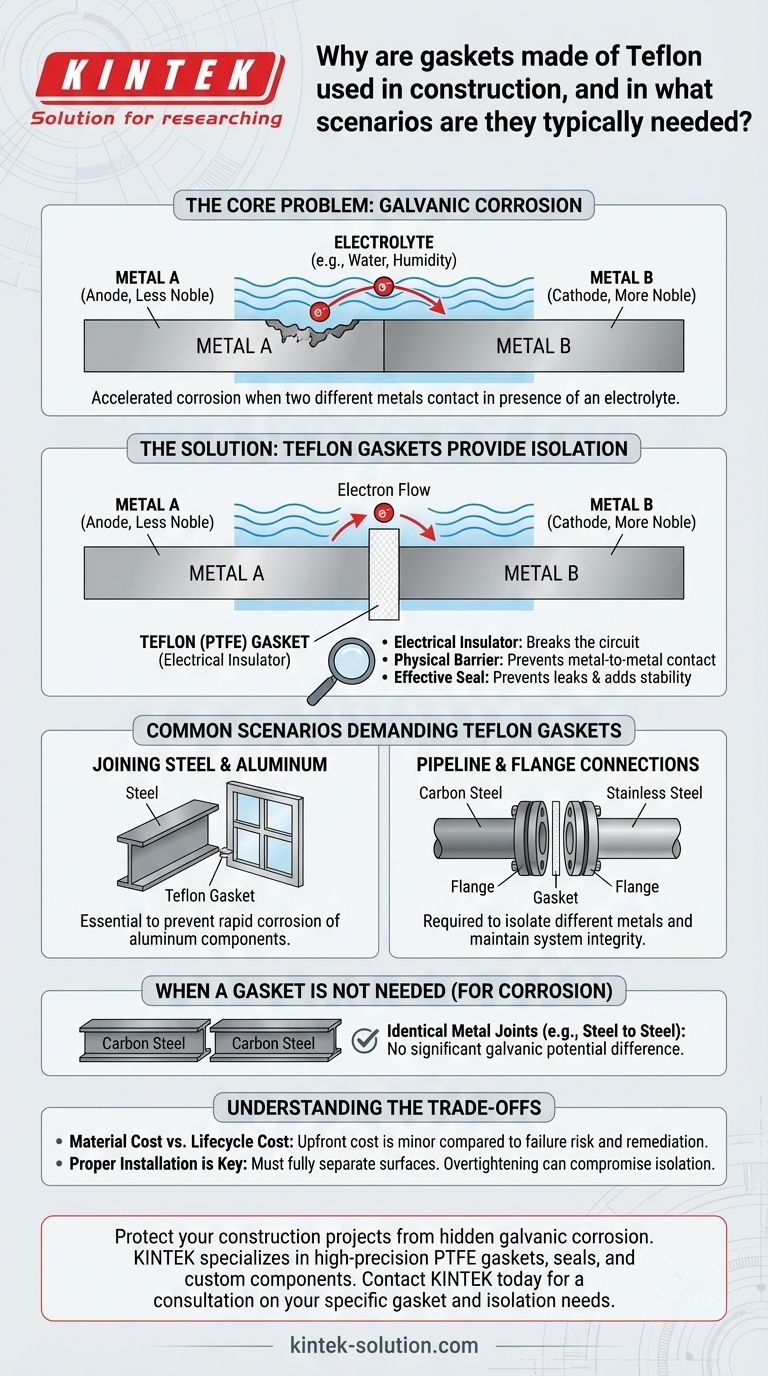

The Core Problem: Galvanic Corrosion

What is Galvanic Corrosion?

Galvanic corrosion is an accelerated form of corrosion that occurs when two different metals are in electrical contact with each other in the presence of an electrolyte.

In this scenario, one metal becomes the anode (less noble) and corrodes at a much faster rate, while the other becomes the cathode (more noble) and is protected.

The Role of an Electrolyte

An electrolyte is a liquid that can conduct electricity, and in construction, this is most often water.

This doesn't require a submerged connection; even atmospheric humidity, rain, or condensation can act as a sufficient electrolyte to initiate the corrosive process.

Why This Matters in Construction

Unchecked galvanic corrosion can weaken structural bolts, flanges, and connection points, leading to a loss of structural integrity.

This gradual degradation is often hidden from view within the joint, making it a significant safety risk that can lead to unexpected failures and costly repairs.

How Teflon Gaskets Provide the Solution

Acting as an Electrical Insulator

Teflon, or Polytetrafluoroethylene (PTFE), is an excellent electrical insulator. It does not conduct electricity.

By placing a Teflon gasket between the surfaces of two different metals, you effectively break the electrical circuit required for galvanic corrosion to occur.

Preventing Metal-to-Metal Contact

The gasket creates a physical barrier that prevents the faying surfaces of the dissimilar metals from touching.

This separation stops the flow of electrons between the anode and cathode, halting the corrosive reaction before it can begin.

Additional Benefits: Sealing and Stability

Beyond corrosion prevention, Teflon gaskets are highly effective seals.

In pipeline systems and other connections, they prevent leaks and add stability to the joint, ensuring a tight and secure fit.

Common Scenarios Demanding Teflon Gaskets

Joining Steel and Aluminum

This is a classic and critical use case. When connecting steel support structures to aluminum components like window frames, curtain walls, or facade panels, a Teflon gasket is essential to prevent the rapid corrosion of the aluminum.

Pipeline and Flange Connections

In industrial and commercial plumbing, it's common for pipes, valves, and flanges to be made of different materials, such as carbon steel and stainless steel.

Isolating gaskets are required at these transition points to maintain the long-term integrity of the pipeline.

When a Gasket Is Not Needed

For connections involving identical metals, such as a carbon steel to carbon steel joint, there is no significant galvanic potential difference.

In these cases, an isolating Teflon gasket is not necessary for preventing galvanic corrosion, though a different type of sealant or gasket may be used for other purposes.

Understanding the Trade-offs

Material Cost vs. Lifecycle Cost

Teflon gaskets and associated isolating sleeves for bolts represent an added upfront material cost compared to a direct metal-to-metal connection.

However, this minor initial expense is insignificant when compared to the enormous potential cost of structural failure, liability, and remediation down the line.

Proper Installation is Key

The effectiveness of the gasket depends entirely on correct installation. The gasket must fully separate the surfaces, and bolt holes often require insulating sleeves and washers to prevent the fasteners from creating an electrical bridge.

Overtightening can also damage the gasket, compromising both its sealing and isolating properties. The cost of omission is the true risk factor.

Making the Right Choice for Your Connection

By understanding the underlying principle, you can specify the correct connection with confidence.

- If your primary focus is structural integrity between dissimilar metals (e.g., steel and aluminum): A Teflon isolating gasket is non-negotiable to prevent galvanic corrosion and ensure long-term safety.

- If your primary focus is joining identical metals (e.g., carbon steel to carbon steel): An isolating gasket is typically unnecessary for corrosion prevention.

- If your primary focus is pipeline systems with mixed-metal components: Use Teflon isolating gasket kits at any connection point involving different metals to prevent both leaks and corrosion-induced failure.

By correctly identifying the need for an isolating gasket, you are making a critical decision that protects the long-term integrity and safety of the structure.

Summary Table:

| Scenario | Gasket Needed? | Primary Reason |

|---|---|---|

| Joining Steel & Aluminum | Yes | Prevent rapid corrosion of aluminum (anode) |

| Pipeline Flanges (Mixed Metals) | Yes | Isolate different metals (e.g., carbon steel & stainless steel) |

| Identical Metal Joints (e.g., Steel to Steel) | No | No significant galvanic potential difference |

Protect your construction projects from hidden galvanic corrosion. KINTEK specializes in manufacturing high-precision PTFE (Teflon) gaskets, seals, and custom components for the construction, industrial, and semiconductor sectors. Whether you need standard parts or custom fabrication from prototypes to high-volume orders, our expertise ensures your connections are safe, durable, and compliant.

Contact KINTEK today for a consultation on your specific gasket and isolation needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments