The choice between PTFE and EPDM valve seats is a critical decision that hinges on two primary factors: chemical compatibility and operating temperature. Polytetrafluoroethylene (PTFE) is the superior choice for aggressive chemicals, solvents, and high-temperature applications due to its inert nature. In contrast, Ethylene Propylene Diene Monomer (EPDM) is the industry standard for water, steam, and general-purpose applications where its durability and flexibility are paramount.

The decision is not about which material is "better," but which is fundamentally compatible with your specific process fluid and operating temperature. Selecting the wrong material is not a minor inefficiency; it is a direct path to premature valve failure, leaks, and potential system-wide contamination.

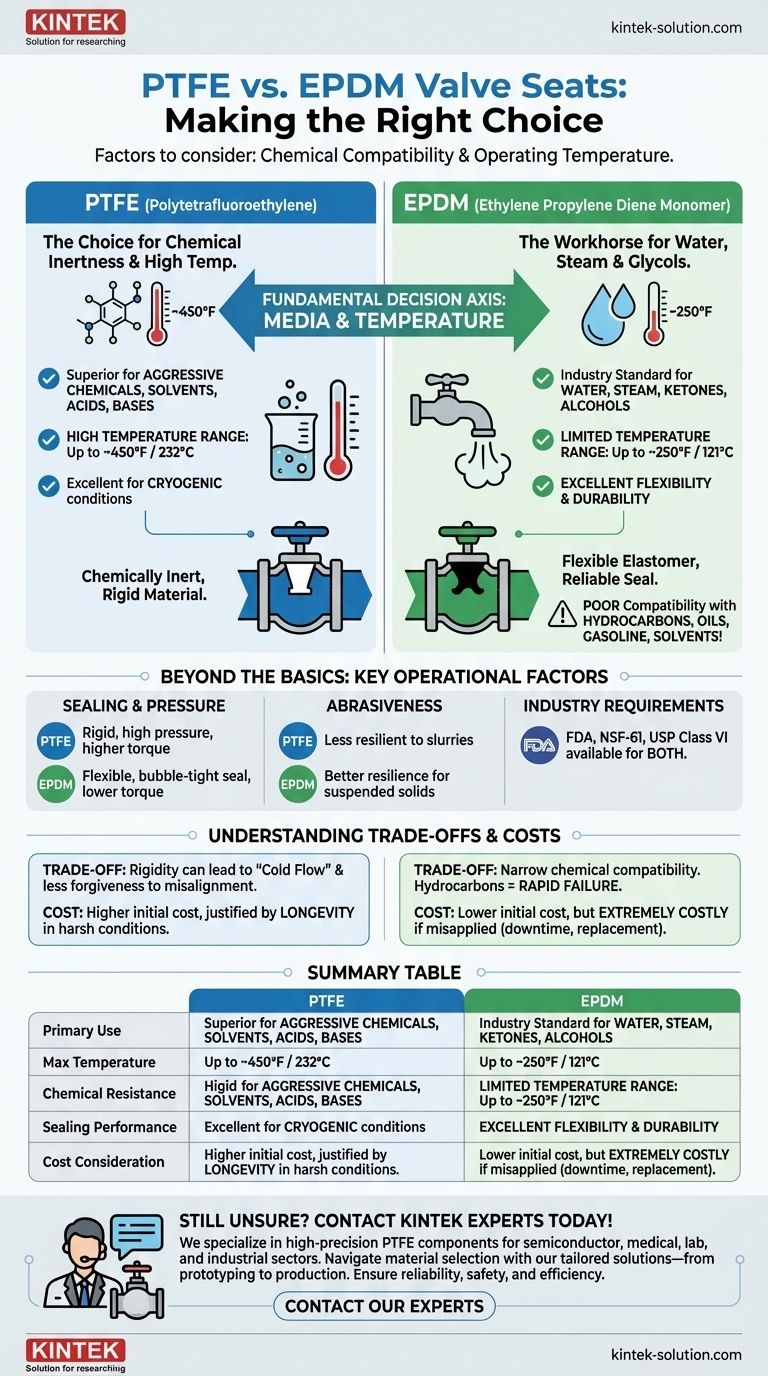

The Fundamental Decision Axis: Media and Temperature

Your first and most important step is to analyze the chemical makeup of the media flowing through the valve and the system's temperature range. This single step will guide you to the correct material in most scenarios.

PTFE: The Choice for Chemical Inertness

PTFE is a fluoropolymer known for its exceptional resistance to a vast range of chemicals, including most acids, bases, and solvents. It is one of the most chemically inert materials used in industrial applications.

This material also has a very wide operating temperature range, performing reliably in both cryogenic conditions and high-heat environments (typically up to ~450°F / 232°C).

EPDM: The Workhorse for Water and Glycols

EPDM is a synthetic rubber (elastomer) that offers excellent resistance to water, steam, ketones, alcohols, and dilute acids. It is highly durable and flexible, providing a reliable seal.

Its primary limitation is its poor compatibility with hydrocarbon oils, gasoline, and most solvents, which will cause the material to swell, degrade, and fail quickly. Its temperature range is also more limited than PTFE (typically up to ~250°F / 121°C).

The Critical Role of Data Sheets

General temperature ranges are a good guide, but always consult the manufacturer's specific data sheet for the valve seat. The precise formulation and manufacturing process can alter a material's pressure and temperature limits.

Beyond the Basics: Key Operational Factors

Once you've narrowed down the choice based on media and temperature, consider these secondary factors to ensure optimal performance and longevity.

Sealing Performance and Pressure

Because EPDM is a flexible elastomer, it often provides a superior, bubble-tight seal with less actuation torque, especially in lower-pressure systems.

PTFE is a more rigid material. While it performs well under high pressure, it can be less forgiving to imperfections and may require higher torque from an actuator to achieve a perfect seal.

Abrasiveness of the Media

For media containing suspended solids or light slurries, the flexibility of an EPDM seat can offer better resilience against abrasive wear compared to the more rigid PTFE.

However, for highly abrasive applications, neither material may be optimal, and you should consider a valve designed specifically for that service.

Industry-Specific Requirements

In industries like pharmaceuticals, food, and beverage, materials must meet strict regulatory standards. Both PTFE and EPDM are available in FDA-compliant grades.

It is your responsibility to verify that the specific material you select carries the necessary certifications for your application, such as FDA, NSF-61 for potable water, or USP Class VI.

Understanding the Trade-offs and Costs

Choosing a valve seat involves balancing performance characteristics with practical limitations. Understanding these trade-offs is key to avoiding costly errors.

The Rigidity of PTFE

PTFE's rigidity makes it durable but also susceptible to "cold flow," which is a slow, permanent deformation under sustained pressure. This can be a factor in applications with high, constant pressure differentials. It is also less forgiving of pipe misalignment during installation.

The Chemical Limitations of EPDM

The primary trade-off with EPDM is its narrow chemical compatibility. Using it with any hydrocarbon-based fluid is a common and critical mistake that guarantees rapid failure. Always verify your media against an EPDM compatibility chart if you have any doubts.

Total Cost of Ownership

While an EPDM-seated valve is often less expensive upfront, it becomes extremely costly if misapplied. The price of frequent valve replacement, system downtime, and potential safety incidents far outweighs the initial savings.

The higher initial cost of a PTFE-seated valve is easily justified by its longevity and reliability in the correct chemically aggressive application.

Making the Right Choice for Your Application

Use these guidelines to finalize your decision based on your primary operational goal.

- If your primary focus is chemical processing: Choose PTFE for its superior resistance to aggressive media and its broad temperature tolerance.

- If your primary focus is water, steam, or HVAC systems: Select EPDM for its proven durability, excellent sealing performance, and cost-effectiveness in these common applications.

- If your primary focus is food, beverage, or pharmaceuticals: Verify the specific grade of either PTFE or EPDM meets all necessary certifications (e.g., FDA-compliant).

- If you are handling oils, fuels, or hydrocarbon-based fluids: Avoid EPDM entirely and select PTFE or another compatible material like Buna-N (Nitrile) or FKM (Viton).

Ultimately, a correct material choice based on a thorough analysis of your media and operating conditions is the foundation of a reliable and safe fluid control system.

Summary Table:

| Factor | PTFE | EPDM |

|---|---|---|

| Primary Use | Aggressive chemicals, solvents, high-temp | Water, steam, general-purpose |

| Max Temperature | ~450°F / 232°C | ~250°F / 121°C |

| Chemical Resistance | Excellent (acids, bases, solvents) | Good (water, steam, ketones); Poor (oils, fuels) |

| Sealing Performance | Rigid, may require higher torque | Flexible, provides bubble-tight seal |

| Cost Consideration | Higher initial cost, justified in harsh conditions | Lower initial cost, costly if misapplied |

Still Unsure Which Valve Seat is Right for Your Application?

Choosing the wrong material can lead to premature failure, leaks, and costly downtime. KINTEK specializes in manufacturing high-precision PTFE components, including custom valve seats, for the semiconductor, medical, laboratory, and industrial sectors.

We can help you navigate material selection and provide a solution tailored to your specific media, temperature, and pressure requirements—from prototyping to high-volume production.

Contact our experts today for a consultation to ensure your fluid control system is reliable, safe, and efficient.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability