In the food processing industry, PTFE rotary shaft lip seals provide a critical barrier against contamination by combining unmatched chemical resistance with high-performance physical properties. This makes them essential for equipment like mixers and pumps, where maintaining stringent hygiene standards and complying with regulations is non-negotiable.

The core benefit of PTFE seals in food applications is their ability to provide a chemically inert, non-contaminating seal that withstands aggressive cleaning processes and demanding operations. This directly supports food safety, reduces maintenance, and enhances equipment reliability.

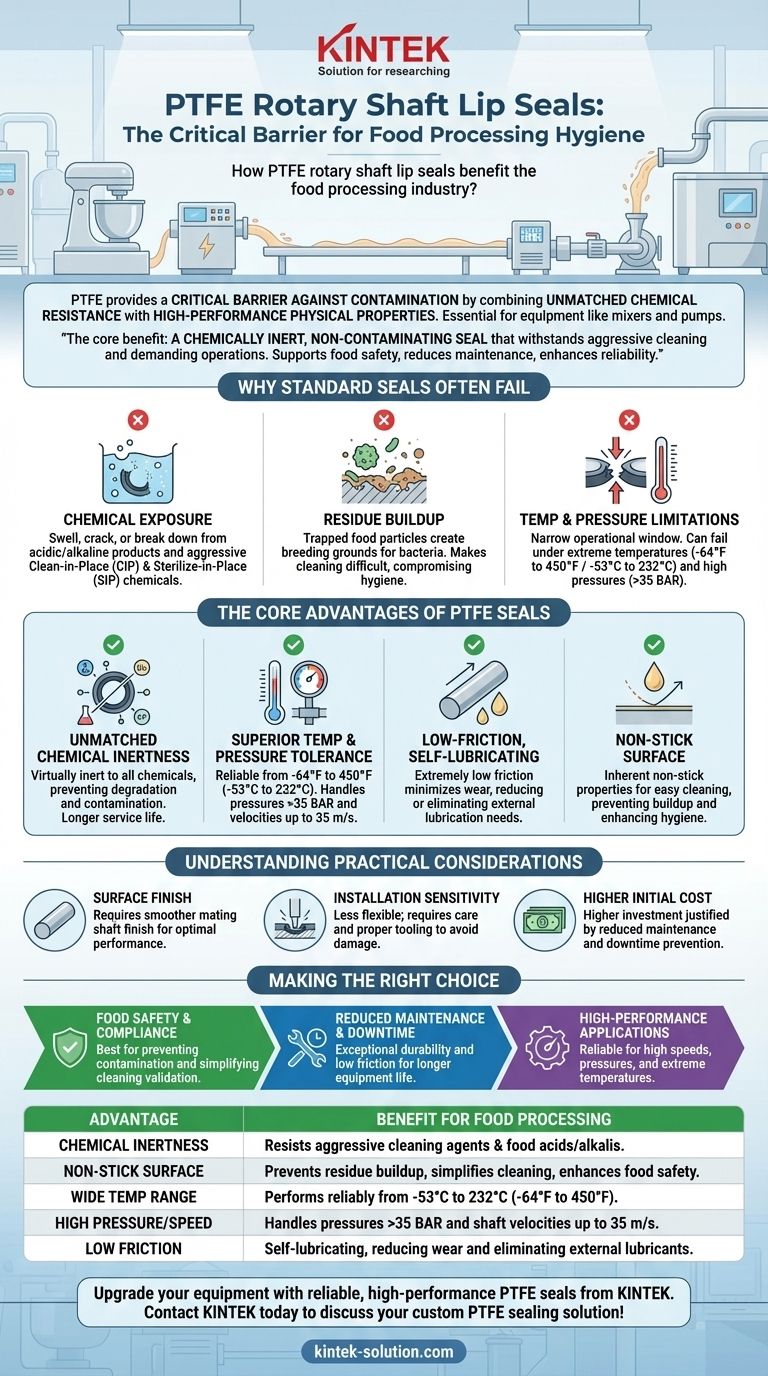

Why Standard Seals Often Fail in Food Processing

The food and beverage industry presents a uniquely hostile environment for sealing components. Traditional elastomeric seals can quickly degrade, leading to contamination and costly downtime.

The Challenge of Chemical Exposure

Standard seals often swell, crack, or break down when exposed to acidic or alkaline food products. More importantly, they are frequently damaged by the aggressive Clean-in-Place (CIP) and Sterilize-in-Place (SIP) chemicals used for sanitation.

The Problem of Residue Buildup

Many conventional sealing materials have surfaces that can trap food particles and residue. This creates a breeding ground for bacteria and makes effective cleaning difficult, compromising hygiene and product safety.

Limitations of Temperature and Pressure

Food processing can involve extreme temperatures and high pressures, from cooking and pasteurization to high-pressure pumping. Standard seals often have a narrow operational window and can fail under these demanding conditions.

The Core Advantages of PTFE Seals

Polytetrafluoroethylene (PTFE) is not just another material; its fundamental properties directly solve the core challenges of sealing in food and beverage applications.

Unmatched Chemical Inertness

PTFE is virtually inert to all chemicals, including the aggressive cleaning agents and acidic food products that cause other seals to fail. This resistance prevents seal degradation, ensuring a longer service life and eliminating a potential source of contamination.

Superior Temperature and Pressure Tolerance

PTFE seals operate reliably across an exceptionally wide temperature range, from approximately -64°F to 450°F (-53°C to 232°C). They are also engineered to handle significantly higher pressures (exceeding 35 BAR) and shaft velocities (up to 35 m/s) than conventional seals.

Low-Friction, Self-Lubricating Performance

With an extremely low coefficient of friction, PTFE glides smoothly over shafts, minimizing wear on both the seal and the equipment. This self-lubricating characteristic is critical in food applications, as it can reduce or even eliminate the need for external lubrication, further reducing contamination risk.

Non-Stick Surface for Enhanced Hygiene

The inherent non-stick properties of PTFE are a major advantage for food safety. This quality allows for the easy removal of product residue during cleaning cycles, preventing buildup and ensuring equipment can be sanitized effectively.

Understanding the Practical Considerations

While PTFE offers superior performance, its successful implementation depends on understanding its unique characteristics. It is not a simple drop-in replacement for all elastomeric seals.

The Importance of Surface Finish

To achieve optimal performance and seal life, PTFE seals require a smoother mating shaft surface finish compared to many traditional seals. An improperly prepared shaft can cause premature wear.

Installation Sensitivity

PTFE is a less flexible material than common elastomers. This means installation requires greater care and proper tooling to avoid damaging the seal lip, which could compromise its effectiveness from the start.

Higher Initial Cost

High-performance materials come at a higher initial cost. However, this investment is typically justified by reduced maintenance, less frequent replacement, and the prevention of costly downtime and product contamination events.

Making the Right Choice for Your Equipment

Choosing the right seal is a critical decision that impacts operational efficiency and product safety. Base your choice on your most critical operational goal.

- If your primary focus is food safety and compliance: PTFE's chemical inertness and non-stick surface make it the definitive choice for preventing contamination and simplifying cleaning validation.

- If your primary focus is reducing maintenance and downtime: The exceptional durability, low friction, and wide operational range of PTFE seals directly contribute to longer equipment life and fewer service interruptions.

- If your primary focus is high-performance applications: For equipment involving high speeds, pressures, or extreme temperatures, PTFE is one of the few materials that can reliably meet these demands without compromising hygiene.

Ultimately, selecting PTFE rotary shaft seals is an investment in operational reliability and the integrity of your final product.

Summary Table:

| Advantage | Benefit for Food Processing |

|---|---|

| Chemical Inertness | Resists aggressive cleaning agents (CIP/SIP) and food acids/alkalis. |

| Non-Stick Surface | Prevents residue buildup, simplifies cleaning, and enhances food safety. |

| Wide Temp Range | Performs reliably from -53°C to 232°C (-64°F to 450°F). |

| High Pressure/Speed | Handles pressures >35 BAR and shaft velocities up to 35 m/s. |

| Low Friction | Self-lubricating, reducing wear and eliminating external lubricants. |

Upgrade your food processing equipment with reliable, high-performance PTFE seals from KINTEK.

Our precision-manufactured PTFE components—including seals, liners, and labware—are designed to meet the stringent demands of the semiconductor, medical, laboratory, and industrial sectors. We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit for your specific application.

Invest in seals that guarantee hygiene, reduce maintenance, and prevent costly downtime. Contact KINTEK today to discuss your custom PTFE sealing solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications