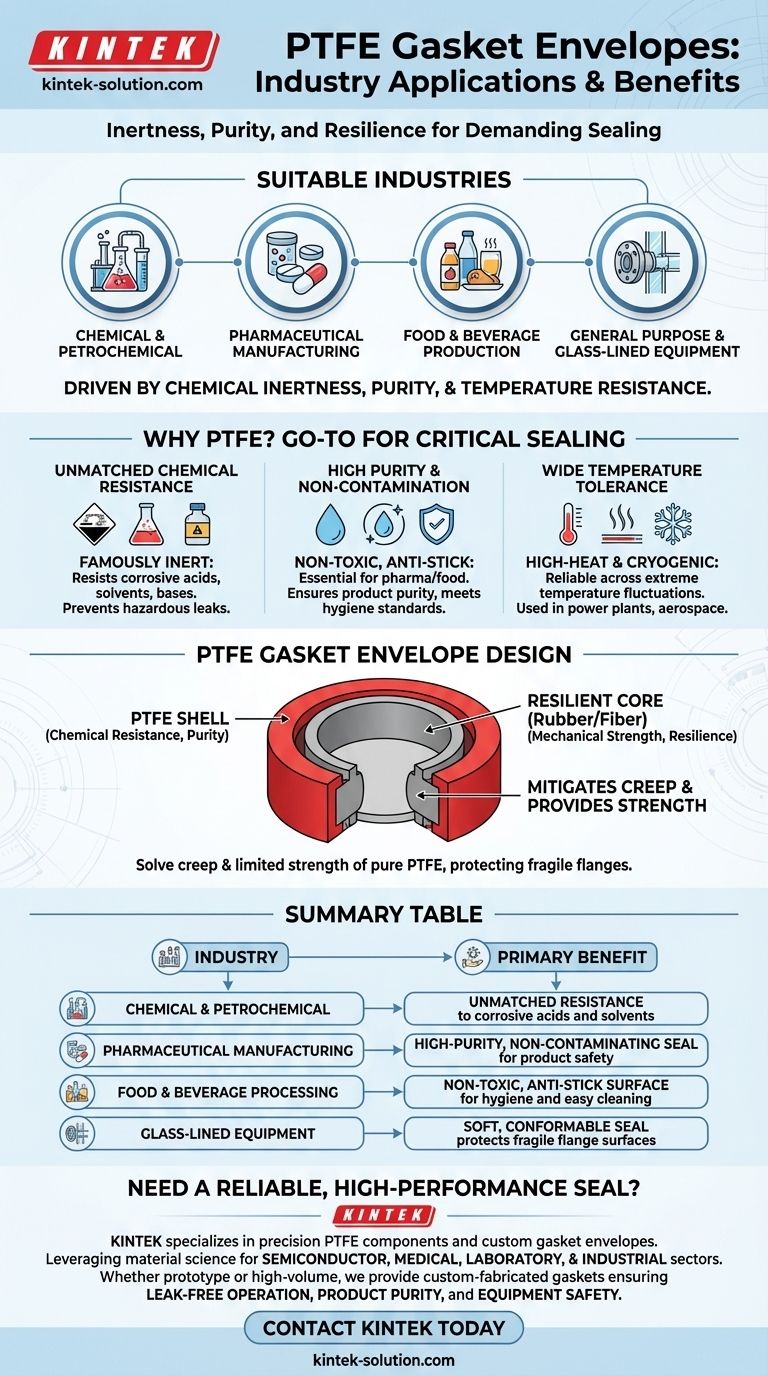

In short, PTFE gasket envelopes are suitable for a wide range of demanding industries, including chemical and petrochemical processing, pharmaceutical manufacturing, food and beverage production, and for use in general-purpose piping and glass-lined equipment. Their selection is driven by a unique combination of chemical inertness, purity, and temperature resistance.

The core reason for PTFE's widespread use is its near-universal chemical resistance and non-contaminating surface. The "envelope" design specifically leverages these properties while using a different core material to provide the mechanical strength and resilience that pure PTFE lacks.

Why PTFE Is a Go-To for Critical Sealing

The suitability of a PTFE gasket envelope comes down to the exceptional properties of Polytetrafluoroethylene (PTFE) itself. Industries don't choose it by accident; they choose it to solve specific, difficult sealing challenges.

Unmatched Chemical Resistance

PTFE is famously inert, meaning it does not react with the vast majority of chemicals. This makes it an essential material for gaskets that will be exposed to aggressive or corrosive acids, solvents, and bases.

This property is the primary reason for its dominance in the chemical and petrochemical industries, where preventing leaks of hazardous materials is a top priority.

High Purity and Non-Contamination

The material is non-toxic, non-absorbent, and has an anti-stick surface. Nothing leaches out of it, and products do not readily adhere to it.

This makes it indispensable for pharmaceutical and food & beverage applications. It ensures that the final product remains pure and uncontaminated by the processing equipment, meeting strict hygiene and safety standards.

Wide Temperature Tolerance

PTFE performs reliably across a very broad temperature range. It can withstand both high-heat processes and cryogenic applications without becoming brittle or degrading.

This versatility makes it useful in power plants (handling high-pressure steam), aerospace, and various chemical processes that involve extreme temperature fluctuations.

Key Industry Applications in Detail

While PTFE as a material is used broadly, the gasket envelope design is particularly valued where a reliable seal is needed on fragile or easily damaged flange surfaces.

Chemical and Petrochemical Plants

In this sector, PTFE envelopes are used to seal connections in piping systems, reactors, and storage tanks. They prevent leaks of corrosive substances, protecting both personnel and the environment.

Pharmaceutical Manufacturing

Here, the focus is on sanitary conditions. PTFE gasket envelopes provide a sterile, non-reactive seal for vessels and piping, ensuring that sensitive biological and chemical compounds are not compromised during production.

Food and Beverage Processing

Similar to pharmaceuticals, the food industry relies on PTFE's non-toxic and non-stick properties. It ensures product purity for items like oils, syrups, and other consumables and allows for easy "clean-in-place" (CIP) procedures.

Sealing Glass-Lined Equipment

Glass-lined steel is common in chemical and pharmaceutical processing because of its corrosion resistance. However, the glass flange surfaces are brittle and easily damaged.

A PTFE envelope gasket is soft and compressible, creating a tight seal without concentrating stress that could crack or chip the delicate glass lining.

Understanding the Trade-offs

No material is perfect. The genius of the PTFE envelope gasket lies in how it mitigates the inherent weaknesses of pure PTFE.

The Problem of Creep (Cold Flow)

Pure PTFE has a tendency to "creep" or cold-flow under sustained pressure and temperature, which can cause a seal to loosen over time.

The envelope design solves this. The PTFE forms only a thin outer shell, while a more resilient inner core material (like rubber or non-asbestos fiber) provides the mechanical stability and resistance to creep.

Limited Mechanical Strength

PTFE is a relatively soft material and is not ideal for high-pressure applications on its own. It lacks the rigidity and "spring-back" of other gasket materials.

Again, the insert material within the envelope provides this crucial compressive strength, ensuring the gasket maintains a tight seal even as system pressures fluctuate.

Making the Right Choice for Your Goal

The decision to use a PTFE gasket envelope should be based on the specific demands of your application.

- If your primary focus is handling aggressive chemicals: A PTFE envelope is almost certainly the correct choice to ensure seal integrity and prevent corrosion.

- If your primary focus is product purity and hygiene: The non-contaminating surface of PTFE is essential for applications in the food, beverage, and pharmaceutical industries.

- If your primary focus is sealing fragile flanges like glass or plastic: The soft, conformable nature of a PTFE envelope provides a safe and effective seal without risking damage to the equipment.

Ultimately, a PTFE envelope gasket is an engineered solution that delivers the superior chemical resistance of PTFE while compensating for its mechanical limitations.

Summary Table:

| Industry | Primary Benefit of PTFE Envelope Gasket |

|---|---|

| Chemical & Petrochemical | Unmatched resistance to corrosive acids and solvents |

| Pharmaceutical Manufacturing | High-purity, non-contaminating seal for product safety |

| Food & Beverage Processing | Non-toxic, anti-stick surface for hygiene and easy cleaning |

| Glass-Lined Equipment | Soft, conformable seal that protects fragile flange surfaces |

Need a reliable, high-performance seal for your critical application?

KINTEK specializes in manufacturing precision PTFE components, including custom gasket envelopes, for the semiconductor, medical, laboratory, and industrial sectors. We leverage our expertise in material science to deliver solutions that combine the chemical inertness of PTFE with the mechanical strength required for your specific operating conditions.

Whether you need a prototype or a high-volume order, our team can provide a custom-fabricated gasket that ensures leak-free operation, protects your product purity, and safeguards your equipment.

Contact KINTEK today to discuss your sealing requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is Teflon used as an insulator? Unmatched Signal Integrity & Chemical Resistance

- What are the main benefits of PTFE-lined bearings? Achieve Maintenance-Free, High-Performance Motion

- What are the benefits of PTFE butterfly valves in industrial applications? Enhance Safety, Purity & Efficiency

- What are the key characteristics of Polytetrafluoroethylene (PTFE) in gland packings? Maximize Sealing Performance

- What is PTFE and why is it used in mechanical seals? Unmatched Chemical Resistance & Low Friction

- What are the key properties of PTFE that make it suitable for lined bearings? Discover the Ultimate Low-Friction Solution

- What safety precautions are needed when machining Teflon? A Guide to Preventing Toxic Fumes

- Why are PTFE lined valves preferred globally? Achieve Superior Corrosion Resistance & Cost Savings