To machine Teflon safely, you must focus on controlling heat. The primary danger arises when Polytetrafluoroethylene (PTFE) is heated above 250°C (482°F), at which point it decomposes and releases toxic gases. Therefore, all safety precautions—including robust ventilation, the use of coolants, and sharp tooling—are fundamentally designed to prevent the material from ever reaching this critical temperature threshold.

The core challenge of machining Teflon is not its hardness, but its thermal and mechanical instability. Consequently, the key to ensuring both operator safety and part quality is aggressive heat management, as excessive temperature is the root cause of both toxic fume release and dimensional inaccuracy.

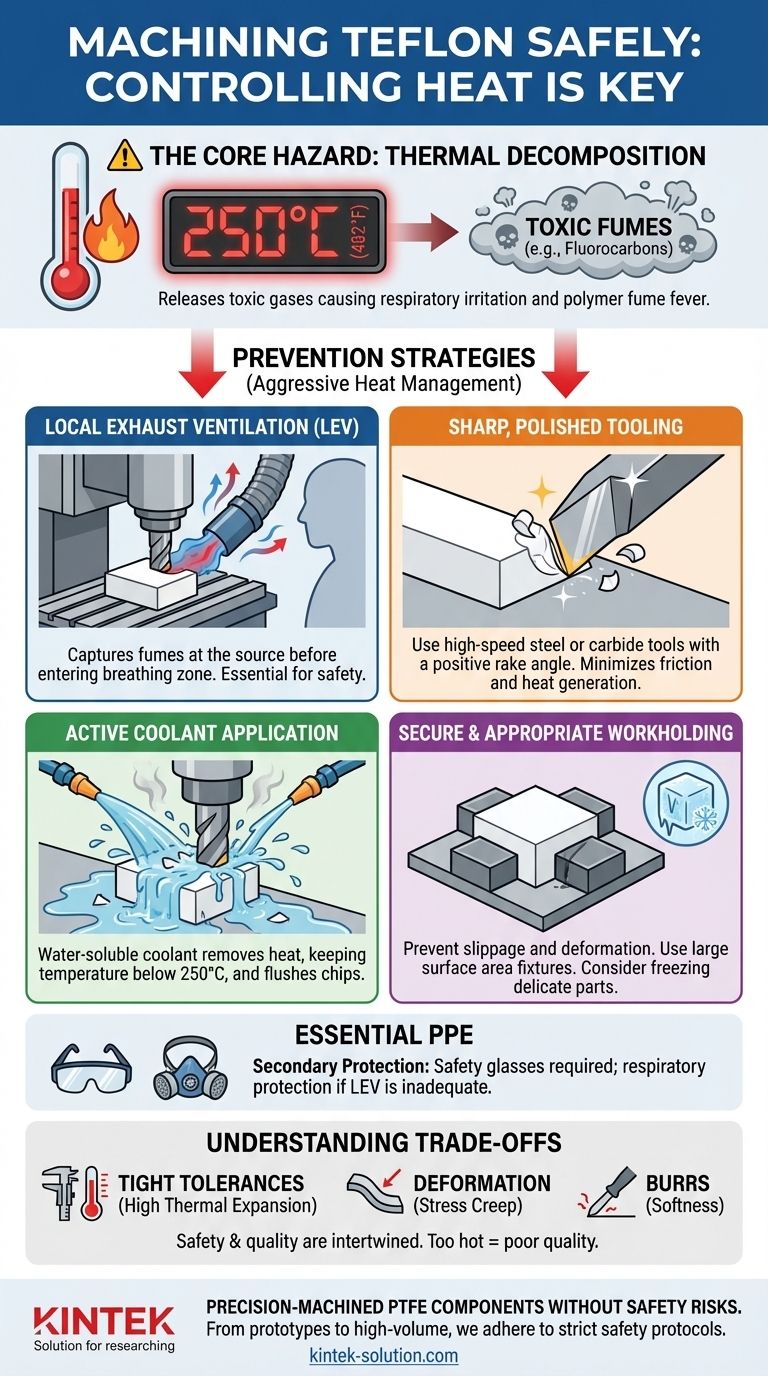

The Core Hazard: Thermal Decomposition

The most significant risk associated with machining Teflon is not mechanical but chemical. Understanding this thermal sensitivity is the foundation of a safe operating procedure.

Understanding the Temperature Threshold

Teflon (PTFE) is stable at room temperature but begins to break down when heated excessively. Machining friction can easily generate enough localized heat to surpass the 250°C decomposition threshold.

When this happens, the material off-gases toxic fluorocarbon particulates and fumes, which can cause severe respiratory irritation and flu-like symptoms known as "polymer fume fever."

The Critical Role of Ventilation

Because the toxic fumes can be invisible and odorless, relying on general shop ventilation is insufficient. Local Exhaust Ventilation (LEV) systems are essential.

An LEV setup uses a vacuum nozzle positioned directly at the point of machining to capture any potential fumes at their source before they can enter the operator's breathing zone.

Essential Protective Equipment (PPE)

Standard personal protective equipment, including safety glasses, is always required.

If adequate LEV is not available or if there is any uncertainty about fume control, appropriate respiratory protection should be used as a secondary measure.

How Machining Creates the Hazard

The properties that make Teflon a useful material—its softness and low friction—also create the conditions that lead to dangerous heat generation during machining.

Friction and Poor Heat Dissipation

Teflon's softness means that a dull cutting tool will tend to plow through or rub against the material rather than shearing it cleanly. This rubbing action generates significant friction and heat.

Furthermore, Teflon is a poor thermal conductor. Heat does not dissipate quickly through the workpiece; instead, it concentrates directly at the tool's cutting edge, dramatically increasing the risk of reaching the decomposition temperature.

The Challenge of Workholding

Teflon’s very low coefficient of friction makes it slippery and difficult to hold securely in a vise or chuck.

If the workpiece slips during a cut, it can increase friction and unpredictable tool engagement, leading to a sudden spike in heat. Over-tightening the fixture to compensate can deform the soft material, causing inaccuracies.

Practical Strategies for Safe and Precise Machining

The best safety strategy is a machining process that is inherently low-heat. These techniques protect both the operator and the integrity of the finished part.

Prioritize Extremely Sharp Tooling

Using sharp, high-speed steel or carbide tools is non-negotiable. A sharp edge minimizes friction by shearing the material cleanly with less force.

Tools with a positive rake angle and polished surfaces are ideal, as they encourage smooth chip formation and prevent soft Teflon material from sticking to the tool, which would otherwise increase friction.

Implement Active Cooling

Generously applying a water-soluble coolant is one of the most effective ways to manage the process.

The coolant performs two critical functions: it actively removes heat from the cutting zone, keeping the workpiece temperature safely below the 250°C limit, and it helps flush away chips.

Ensure Rigid and Appropriate Workholding

The workpiece must be supported properly to prevent deformation under cutting and clamping forces.

Use fixtures with a large surface area to distribute clamping pressure evenly. For delicate parts, a unique strategy is to temporarily freeze the material before machining to increase its rigidity, which reduces deformation and improves cut quality.

Understanding the Trade-offs and Common Pitfalls

Safety and quality control are deeply intertwined when machining Teflon. A process that is unsafe (too hot) will almost certainly produce a poor-quality part.

The Challenge of Tight Tolerances

Teflon has an extremely high coefficient of thermal expansion. A part machined at a slightly elevated temperature will shrink as it cools, making it difficult to hold tight tolerances. Temperature stability is paramount.

Deformation Under Clamping Pressure

The softness of Teflon means it is susceptible to stress creep. If a part is clamped too tightly, it will slowly deform, leading to an inaccurate final shape even after the pressure is removed.

The Inevitability of Burrs

Because Teflon is so soft, it often tears rather than chips cleanly, leaving burrs along the machined edges. Plan for a post-processing step, such as careful manual deburring or bead blasting, to achieve a clean final surface.

Making the Right Choice for Your Process

Your specific priorities will determine which precautions and techniques you emphasize, but the fundamental principles of heat management remain constant.

- If your primary focus is operator safety: Your non-negotiable priorities are local exhaust ventilation and a constant flood of coolant to keep temperatures far below 250°C.

- If your primary focus is achieving tight tolerances: You must use exceptionally sharp tools, maintain a stable temperature throughout the process, and account for the material's high thermal expansion.

- If your primary focus is surface finish: Employ tools with highly polished surfaces to prevent material buildup and plan for a post-processing step to remove the inevitable burrs.

Ultimately, machining Teflon safely and effectively requires you to respect its thermal limits and accommodate its unique softness at every stage of the process.

Summary Table:

| Safety Precaution | Purpose | Key Details |

|---|---|---|

| Local Exhaust Ventilation (LEV) | Prevent toxic fume inhalation | Captures fumes at source before they enter breathing zone |

| Sharp Tooling | Minimize friction and heat generation | Use high-speed steel/carbide with positive rake angle |

| Coolant Application | Maintain temperature below 250°C | Water-soluble coolant removes heat and flushes chips |

| Secure Workholding | Prevent slippage and deformation | Use large surface area fixtures; consider freezing delicate parts |

| PPE | Secondary protection | Safety glasses; respiratory protection if ventilation is inadequate |

Need precision-machined PTFE components without the safety risks?

At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our advanced machining processes are designed to manage heat effectively, ensuring both operator safety and dimensional accuracy.

We handle everything from prototypes to high-volume orders with strict adherence to safety protocols. Let us take on the machining challenges so you can focus on your application.

Contact KINTEK today for a quote on your custom PTFE fabrication needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications