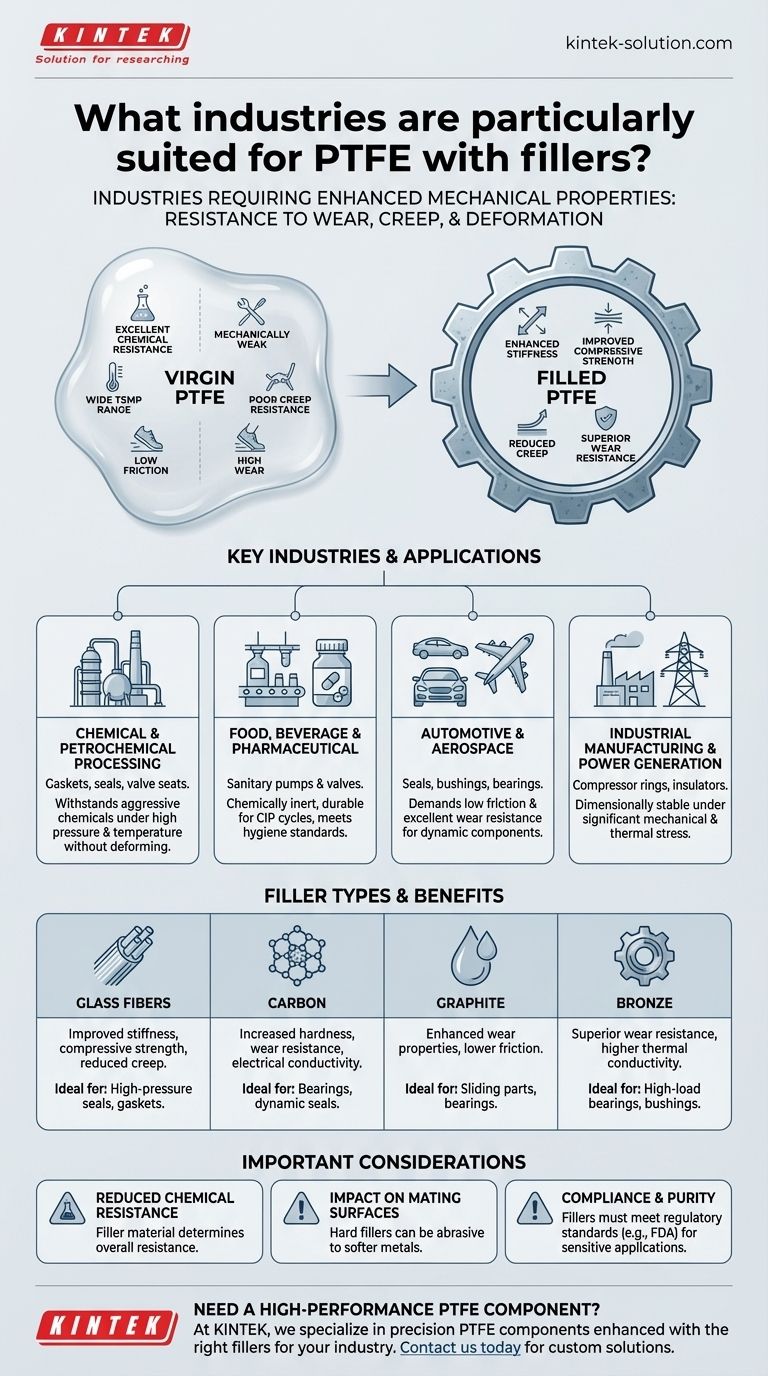

In short, industries that require enhanced mechanical properties like resistance to wear, creep, and deformation under load are particularly suited for PTFE with fillers. The most prominent examples include chemical and petrochemical processing, food and pharmaceutical manufacturing, and demanding automotive or aerospace applications where pure PTFE would be too soft.

The core takeaway is that while virgin PTFE offers exceptional chemical resistance and low friction, it is mechanically weak. Fillers are added to overcome these weaknesses, transforming PTFE into a robust engineering material suitable for high-stress industrial environments like seals, bearings, and gaskets.

The Baseline: Why Virgin PTFE is Valued

To understand the need for fillers, we must first appreciate the inherent strengths of pure, or "virgin," Polytetrafluoroethylene (PTFE).

### Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it an automatic choice for components that will be exposed to corrosive materials, a common scenario in chemical, food, and pharmaceutical processing.

### Wide Service Temperature Range

PTFE maintains its properties across an impressively broad temperature spectrum. It remains stable and functional in applications ranging from cryogenic conditions to elevated temperatures, which is critical in power generation and industrial piping.

### Extremely Low Coefficient of Friction

Known for its non-stick properties, PTFE has one of the lowest coefficients of friction of any solid material. This is highly valuable for applications involving sliding parts, such as bearings or non-stick coatings.

Why Fillers are the Critical Upgrade

Despite its strengths, virgin PTFE has significant mechanical limitations that make it unsuitable for many demanding industrial roles. Fillers are the solution.

### Overcoming Mechanical Weaknesses

The primary drawbacks of virgin PTFE are its poor resistance to creep (or "cold flow") and wear. Under sustained pressure, especially at elevated temperatures, pure PTFE will slowly deform. In dynamic applications with moving parts, it wears down quickly.

### How Fillers Enhance Performance

Adding fillers like glass, carbon, graphite, or bronze to the PTFE matrix fundamentally changes its mechanical behavior.

- Glass fibers dramatically improve stiffness and compressive strength, significantly reducing creep.

- Carbon increases hardness, wear resistance, and provides electrical conductivity.

- Graphite enhances wear properties and further reduces the coefficient of friction.

- Bronze provides the best wear resistance and higher thermal conductivity.

Key Industries for Filled PTFE

These enhanced properties make filled PTFE essential for industries where both chemical resistance and mechanical integrity are non-negotiable.

### Chemical and Petrochemical Processing

This sector relies on filled PTFE for gaskets, seals, and valve seats. The material must withstand aggressive chemicals while maintaining a tight seal under high pressure and temperature without deforming. Virgin PTFE would fail under such loads.

### Food, Beverage, and Pharmaceutical

In these sanitary environments, components in pumps and valves need to be chemically inert and meet hygiene standards. Filled PTFE provides the necessary wear resistance for continuous operation and durability to withstand rigorous cleaning-in-place (CIP) cycles.

### Automotive and Aerospace

Applications like seals, bushings, and bearings in these industries demand low friction and excellent wear resistance. Carbon or bronze-filled PTFE provides the durability needed for these dynamic components, far exceeding the lifespan of virgin PTFE.

### Industrial Manufacturing and Power Generation

High-performance components like compressor rings, insulators, and expansion joints must be dimensionally stable under significant mechanical and thermal stress. Filled PTFE delivers the required rigidity and resistance to wear and creep.

Understanding the Trade-offs

Adding fillers is not a universal improvement. It involves specific design considerations that are critical for success.

### Reduced Chemical Resistance

While still excellent, the chemical resistance of filled PTFE is determined by the filler material itself. An aggressive chemical that does not affect PTFE might attack a glass or bronze filler, compromising the component.

### Impact on Mating Surfaces

Harder fillers, particularly glass fibers, can be abrasive to softer metal surfaces. This is a crucial consideration in dynamic applications, as a filled PTFE bearing could potentially wear down a softer steel shaft over time.

### Compliance and Purity

For food, beverage, or pharmaceutical applications, the filler material itself must meet the same stringent regulatory standards (e.g., FDA approval) as the PTFE.

Making the Right Choice for Your Application

The decision to use virgin or filled PTFE depends entirely on the mechanical demands of the environment.

- If your primary focus is maximum chemical inertness in a static, low-pressure application: Virgin PTFE is the ideal and most cost-effective choice.

- If your primary focus is sealing corrosive fluids under high pressure or temperature: A glass-filled PTFE gasket offers the necessary resistance to creep.

- If your primary focus is a long-lasting bearing or dynamic seal: A carbon or bronze-filled PTFE provides the superior wear resistance required for a long service life.

- If your primary focus is a food-grade component with high durability: Use a filled PTFE where both the polymer and the specific filler are certified for sanitary use.

Ultimately, fillers elevate PTFE from a versatile polymer to a high-performance engineering material tailored to solve specific industrial challenges.

Summary Table:

| Filler Type | Key Benefits | Ideal For |

|---|---|---|

| Glass Fibers | Improved stiffness, compressive strength, reduced creep | High-pressure seals, gaskets |

| Carbon | Increased hardness, wear resistance, electrical conductivity | Bearings, dynamic seals |

| Graphite | Enhanced wear properties, lower friction | Sliding parts, bearings |

| Bronze | Superior wear resistance, higher thermal conductivity | High-load bearings, bushings |

Need a high-performance PTFE component that stands up to your toughest challenges?

At KINTEK, we specialize in manufacturing precision PTFE components—from custom seals and liners to specialized labware—enhanced with the right fillers for your specific industry demands. Whether you're in semiconductor, medical, laboratory, or industrial manufacturing, our custom fabrication services ensure your parts deliver maximum durability, chemical resistance, and longevity.

Contact us today to discuss your project requirements, from prototypes to high-volume orders, and let us help you solve your most demanding application challenges with precision-engineered PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications