The future of CNC machined PTFE is a convergence of advanced digital technologies and material science, pushing the material into applications that demand unprecedented complexity and precision. Key trends include the integration of AI-driven machining and hybrid manufacturing with 3D printing, which will enable more efficient production and expand PTFE’s role in sustainable technologies and next-generation product design.

The core trend is not about changing PTFE's fundamental properties, but about using advanced technology to master its inherent challenges. This allows engineers to fully exploit its unique benefits in more demanding and innovative applications than ever before.

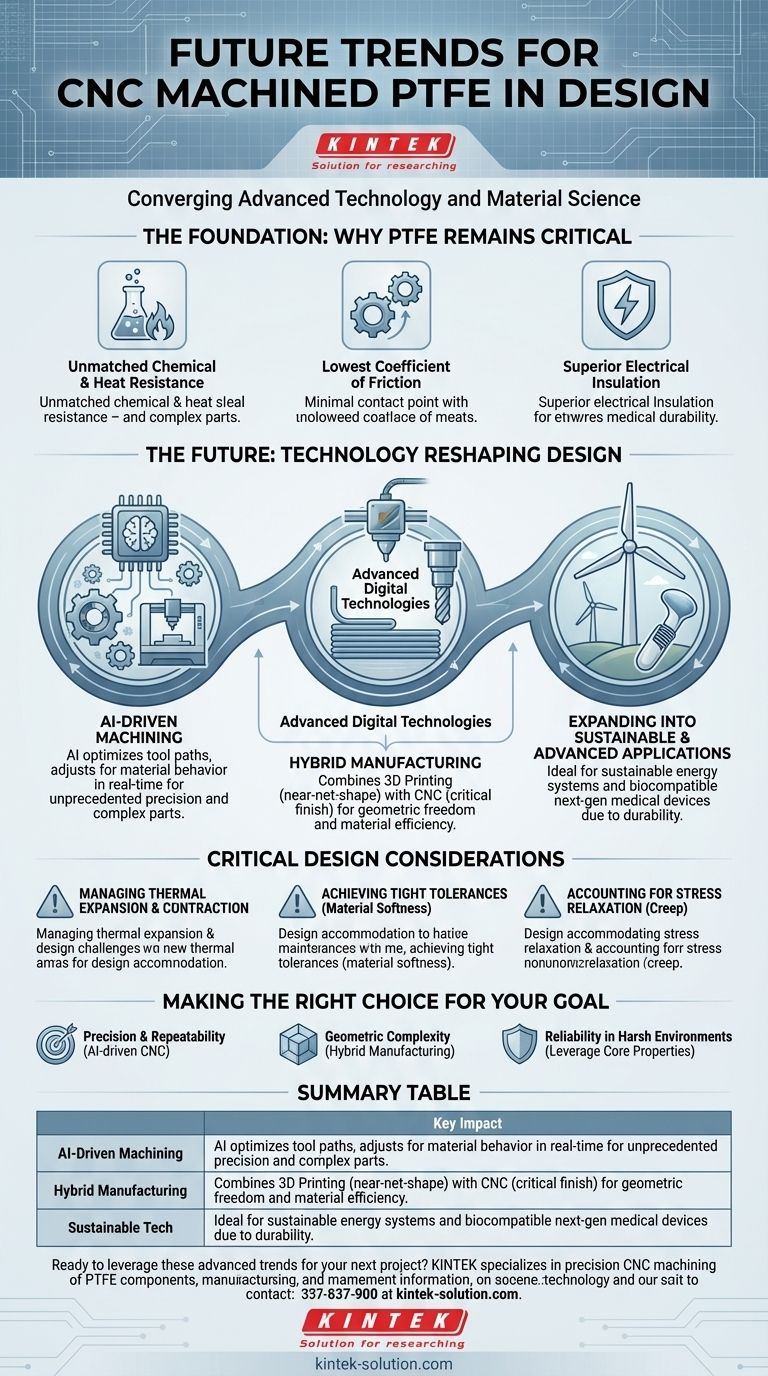

The Foundation: Why PTFE Remains a Critical Material

Before looking forward, it's essential to understand the core properties that make Polytetrafluoroethylene (PTFE) so valuable. These characteristics are the reason it continues to be a focus for technological advancement.

Unmatched Chemical and Heat Resistance

PTFE is famously non-reactive, making it invaluable for components used in corrosive chemical environments or at high temperatures. This stability ensures longevity and reliability where other materials would fail.

The Lowest Coefficient of Friction

Known for its slick, non-stick surface, PTFE has one of the lowest friction coefficients of any solid material. This makes it a first-choice material for bearings, seals, and other low-wear components.

Superior Electrical Insulation

PTFE is an exceptional electrical insulator, maintaining its properties across a wide range of frequencies and temperatures. This makes it indispensable for high-performance wiring, connectors, and insulating components in the electronics industry.

The Future: How Technology is Reshaping PTFE Design

Emerging technologies are set to solve long-standing challenges in machining PTFE, unlocking new possibilities for designers and engineers.

AI-Driven Machining for Unprecedented Precision

Artificial intelligence is beginning to revolutionize the CNC process. AI algorithms can optimize tool paths and cutting speeds in real-time, constantly adjusting for material behavior to achieve a level of precision that was previously difficult and time-consuming.

This allows for the consistent production of highly complex parts with extremely tight tolerances, moving beyond the limitations of traditional programming.

Hybrid Manufacturing: Combining 3D Printing and CNC

The future involves combining the strengths of different manufacturing methods. Additive manufacturing (3D printing) can create complex, near-net-shape PTFE parts, which are then finished with CNC machining to achieve critical tolerances and superior surface finishes.

This hybrid approach allows for geometric freedom and material efficiency that neither process could achieve alone.

Expanding into Sustainable and Advanced Applications

These technological advancements are expanding PTFE’s role in critical future-facing industries. Its durability and resistance make it ideal for components in sustainable energy systems, while its biocompatibility is crucial for next-generation medical devices and implants.

Understanding the Trade-offs: Critical Design Considerations

Even with advanced technology, PTFE's unique material behavior presents challenges that every designer must account for. Technology helps manage these issues, but it doesn't eliminate them.

Managing Thermal Expansion and Contraction

PTFE has a high rate of thermal expansion. Designs must accommodate for how the material will change shape with temperature fluctuations, both during the machining process and in its final application environment.

The Challenge of Achieving Tight Tolerances

As a relatively soft material, PTFE can be difficult to hold to extremely tight tolerances. It is prone to deformation under cutting pressure and can be challenging to fixture securely without marring the surface.

Accounting for Stress Relaxation and Creep

Under a constant load, PTFE parts can slowly deform over time—a phenomenon known as creep or stress relaxation. Engineers must consider this long-term behavior in the design of gaskets, seals, and structural components.

Making the Right Choice for Your Design Goal

Your specific objective will determine which aspect of PTFE's evolution is most relevant to your work.

- If your primary focus is maximum precision and repeatability: Lean into the potential of AI-driven CNC machining to compensate for material instability and achieve consistent, tight tolerances.

- If your primary focus is geometric complexity and novel shapes: Explore hybrid manufacturing, using 3D printing for the initial form and CNC for the critical finishing touches.

- If your primary focus is reliability in harsh environments: Continue to leverage PTFE’s core chemical and thermal resistance, knowing that modern machining can produce more efficient and effective designs.

Ultimately, the future of CNC machined PTFE is about using technology to elevate its inherent strengths, making it a more versatile and powerful tool for innovation.

Summary Table:

| Trend | Key Impact |

|---|---|

| AI-Driven Machining | Enables unprecedented precision and consistent tight tolerances. |

| Hybrid Manufacturing (3D Printing + CNC) | Allows for greater geometric complexity and material efficiency. |

| Expansion into Sustainable Tech | Leverages PTFE's durability for energy systems and medical devices. |

Ready to leverage these advanced trends for your next project?

KINTEK specializes in precision CNC machining of PTFE components like seals, liners, and custom labware. We combine expert knowledge of PTFE's unique properties with state-of-the-art technology to overcome material challenges and deliver high-quality parts—from prototypes to high-volume orders—for the semiconductor, medical, laboratory, and industrial sectors.

Contact us today to discuss how we can bring precision and innovation to your PTFE component design.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments