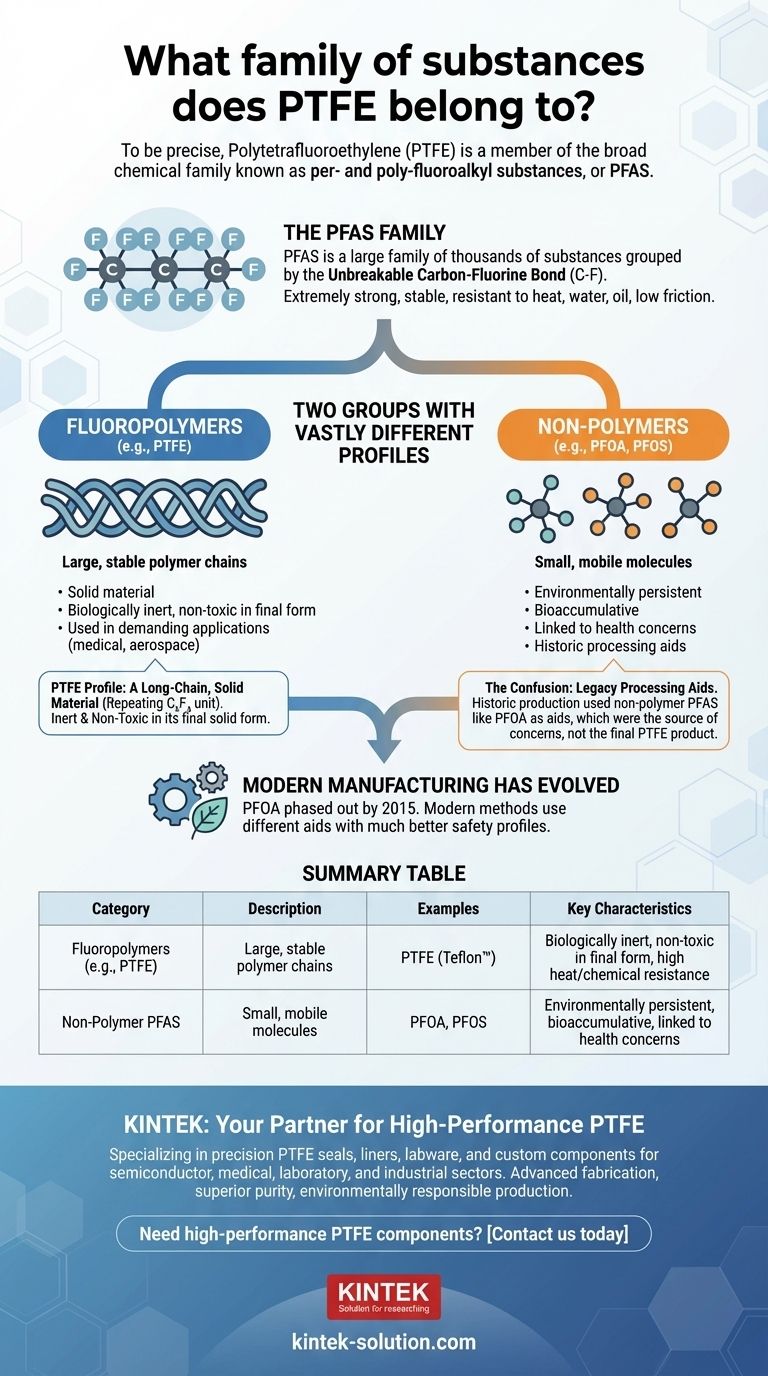

To be precise, Polytetrafluoroethylene (PTFE) is a member of the broad chemical family known as per- and poly-fluoroalkyl substances, or PFAS. While this classification is chemically accurate, it is crucial to understand that PTFE is a specific type of PFAS—a fluoropolymer—with properties vastly different from the smaller PFAS compounds that are the focus of most health and environmental concerns.

The critical distinction is not just that PTFE is a PFAS, but that it is a polymer. Its large, stable, and inert molecular structure gives it a safety and performance profile that is fundamentally different from the smaller, more mobile, and more biologically active non-polymer PFAS molecules.

What Defines the PFAS Family?

PFAS is not a single chemical but a large family containing thousands of distinct substances. They are grouped together because of a shared, defining chemical feature.

The Unbreakable Carbon-Fluorine Bond

At the heart of every PFAS molecule is an extremely strong bond between carbon and fluorine atoms. This is one of the strongest single bonds in organic chemistry.

This powerful bond is the source of the desirable properties of PFAS: extreme stability, resistance to heat, water, and oil, and low friction.

Two Groups with Vastly Different Profiles

The PFAS family can be broadly divided into two main categories: polymers and non-polymers. This distinction is essential for understanding risk.

Fluoropolymers, like PTFE, are large, heavy molecules made of long, repeating chains. They are solids, stable, and generally too large to be absorbed by the body.

Non-polymers, like PFOA and PFOS, are much smaller, more mobile molecules. These are the specific PFAS compounds that have been linked to health concerns because they can move through the environment and accumulate in biological systems.

Where PTFE Fits: A Stable Fluoropolymer

PTFE is the original "non-stick" material, best known by the brand name Teflon. Its identity as a fluoropolymer defines its behavior and use.

A Long-Chain, Solid Material

Think of PTFE as a very long, heavy chain. The repeating unit in this chain is C₂F₄. Because of its size and strength, this molecule is a solid that does not readily break down.

Inert and Non-Toxic in Its Final Form

In its finished, solid state (like the coating on a pan), PTFE is considered biologically inert. It does not react with chemicals inside the body and is not absorbed by it.

This stability is why PTFE and other fluoropolymers are trusted in demanding applications, from medical implants and heart patches to critical aerospace components.

Understanding the Source of Confusion

If PTFE itself is so stable, why is it associated with the controversy surrounding PFAS? The answer lies not in the final product, but in the historical manufacturing process.

Legacy Processing Aids

In the past, the manufacturing of PTFE required the use of smaller, non-polymer PFAS molecules as processing aids. The most notable of these was PFOA (Perfluorooctanoic acid).

These smaller molecules were the primary source of environmental contamination and health concerns associated with PTFE production facilities. They were a problematic ingredient, not the final product.

Modern Manufacturing Has Evolved

Recognizing the risks, major global manufacturers began phasing out PFOA in the early 2000s, a process largely completed by 2015 under voluntary global stewardship programs.

Modern production methods now use different processing aids that have a much better safety profile and are not persistent in the same way PFOA was.

How to Apply This Understanding

Making an informed decision requires moving past the simple "PFAS" label and considering the specific substance and its application.

- If your primary focus is consumer product safety: The finished, intact PTFE coating on cookware is considered safe for use. The main risk comes from overheating pans above 500°F (260°C), at which point the polymer can begin to degrade.

- If your primary focus is environmental impact: The significant environmental concerns were linked to legacy manufacturing aids like PFOA, not the stable PTFE polymer itself. Choosing products from reputable manufacturers ensures modern, cleaner production methods were used.

- If your primary focus is material selection: Recognize that while PTFE is technically a PFAS, its risk profile is fundamentally different from non-polymer PFAS. Its properties as a large, inert polymer make it safe and effective for its intended applications.

Ultimately, understanding that "PFAS" includes both stable polymers and problematic non-polymers is the key to navigating this complex topic.

Summary Table:

| Category | Description | Examples | Key Characteristics |

|---|---|---|---|

| Fluoropolymers (e.g., PTFE) | Large, stable polymer chains | PTFE (Teflon™) | Biologically inert, non-toxic in final form, high heat/chemical resistance |

| Non-Polymer PFAS | Small, mobile molecules | PFOA, PFOS | Environmentally persistent, bioaccumulative, linked to health concerns |

Need high-performance PTFE components tailored to your exact requirements?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our advanced fabrication techniques ensure superior material purity and performance, leveraging modern, environmentally responsible production methods.

We offer custom solutions from prototypes to high-volume orders, delivering the chemical resistance, low friction, and reliability your applications demand.

Contact us today to discuss your project and experience the KINTEK difference!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer