In short, PTFE prices are dictated by three primary forces: the availability of its core raw material, global industrial demand, and overall market conditions. The price of Polytetrafluoroethylene (PTFE) is not arbitrary; it's the result of a sensitive global supply chain that is easily influenced by shifts in mining output and industrial consumption.

The price of PTFE is fundamentally tied to the supply and demand of a single raw material: fluorspar. Understanding the market for this mineral is the key to anticipating PTFE price fluctuations.

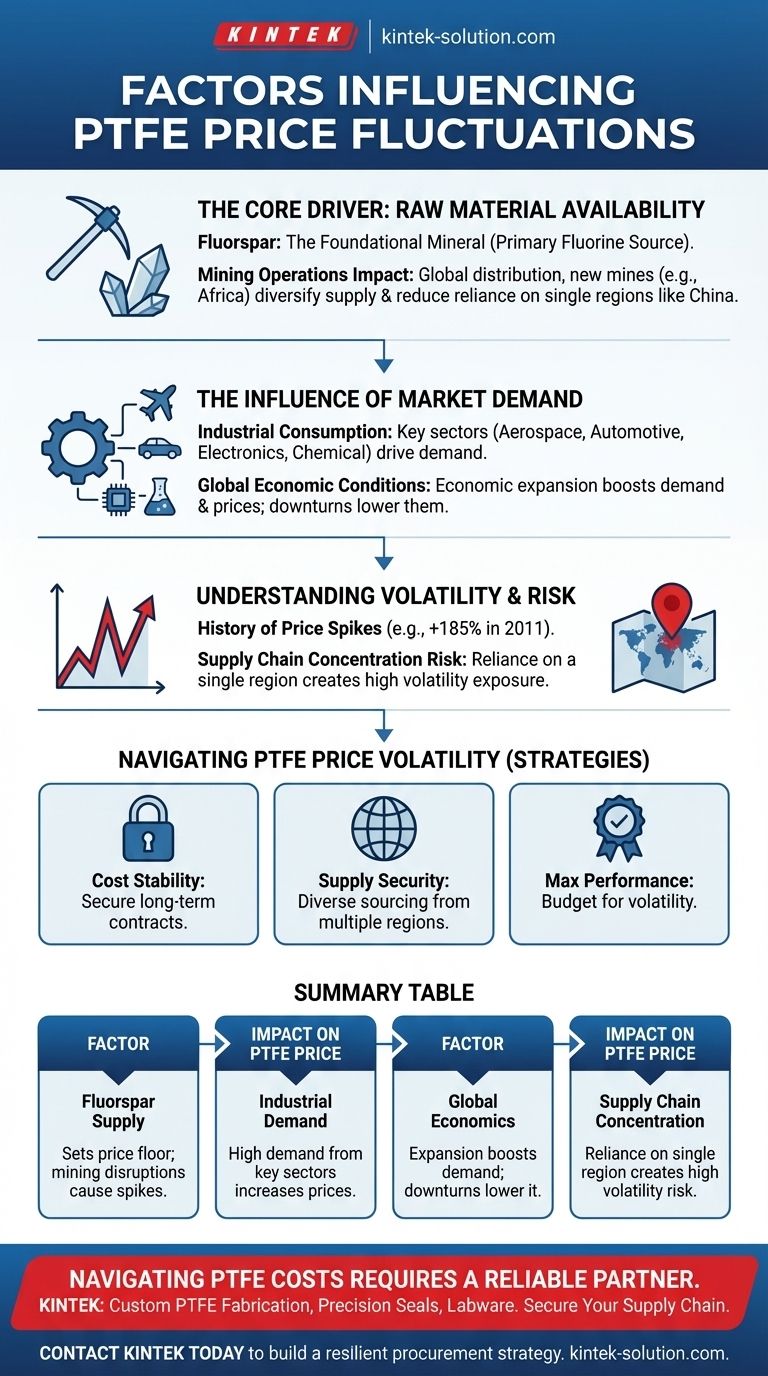

The Core Driver: Raw Material Availability

The entire PTFE supply chain begins deep in the earth. The availability of its foundational component is the single most significant factor influencing its final cost.

Fluorspar: The Foundational Mineral

PTFE is a fluoropolymer, and its journey from raw material to finished product starts with a mineral called fluorspar. This mineral is the primary source of fluorine used in the production process.

Therefore, the cost and availability of mined fluorspar create the price floor for PTFE. Any disruption in fluorspar mining directly translates to price pressure on PTFE.

The Impact of Mining Operations

The global distribution and output of fluorspar mines are critical. Historically, heavy reliance on Chinese supplies created significant price sensitivity.

More recently, the opening of new mines in regions like Africa has helped stabilize the market. This diversification of supply sources can offset regional production issues and reduce the impact of policies from a single country, leading to more predictable pricing.

The Influence of Market Demand

While supply sets the foundation, demand determines the immediate price direction. PTFE's unique properties make it essential in numerous high-value industries.

Industrial Consumption Trends

Demand is not monolithic; it comes from various sectors. Key industries like aerospace, automotive, electronics, and chemical processing are major consumers of PTFE.

A surge in demand from any of these large sectors can strain the existing supply and drive prices upward. Conversely, a slowdown in industrial manufacturing can soften demand and lead to lower prices.

Global Economic Conditions

Broader economic cycles have a direct impact on PTFE demand. During periods of economic expansion, industrial production increases, boosting the need for materials like PTFE.

This creates a competitive market where suppliers can command higher prices. In contrast, economic downturns reduce industrial activity, leading to less demand and more competitive pricing.

Understanding the Volatility

The interplay between a concentrated raw material supply and broad industrial demand creates a naturally volatile market.

A History of Price Spikes

The PTFE market is known for its potential for rapid price increases. In 2011, for instance, the price of virgin PTFE rose by an astonishing 185% due to a perfect storm of supply constraints and high demand.

This historical precedent serves as a crucial reminder of how quickly market dynamics can shift.

The Risk of Supply Chain Concentration

When a large percentage of a critical raw material like fluorspar comes from a single region, the entire global market is exposed to risk.

Factors such as local environmental regulations, export policies, or geopolitical tensions in that one region can create immediate and severe global price shocks. Diversification through new mining locations is the primary strategy to mitigate this risk.

How to Navigate PTFE Price Volatility

Understanding these factors is the first step toward building a resilient procurement strategy. Your approach should be tailored to your primary business objective.

- If your primary focus is cost stability: You may want to secure long-term contracts with suppliers to lock in pricing and insulate your business from short-term market swings.

- If your primary focus is supply security: It is critical to work with suppliers who source raw materials from multiple geographic regions, reducing your exposure to a single point of failure.

- If your primary focus is maximum performance: You must be prepared for price volatility by building potential cost increases into your budget, as high-purity virgin PTFE is the most directly exposed to raw material fluctuations.

By understanding the levers of supply and demand, you can better anticipate market shifts and make proactive decisions for your projects.

Summary Table:

| Factor | Impact on PTFE Price |

|---|---|

| Fluorspar Supply | Directly sets the price floor; mining disruptions cause spikes. |

| Industrial Demand | High demand from sectors like aerospace & electronics increases prices. |

| Global Economics | Economic expansion boosts demand and prices; downturns lower them. |

| Supply Chain Concentration | Reliance on a single region (e.g., China) creates high volatility risk. |

Navigating PTFE costs requires a reliable partner. At KINTEK, we understand the pressures of price volatility on industries like semiconductor, medical, and laboratory. Our expertise in custom PTFE fabrication—from precision seals and liners to complex labware—ensures you get high-performance components tailored to your needs, whether for prototypes or high-volume orders. Let us help you secure your supply chain and optimize your budget.

Contact KINTEK today to discuss your specific requirements and build a resilient procurement strategy.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments