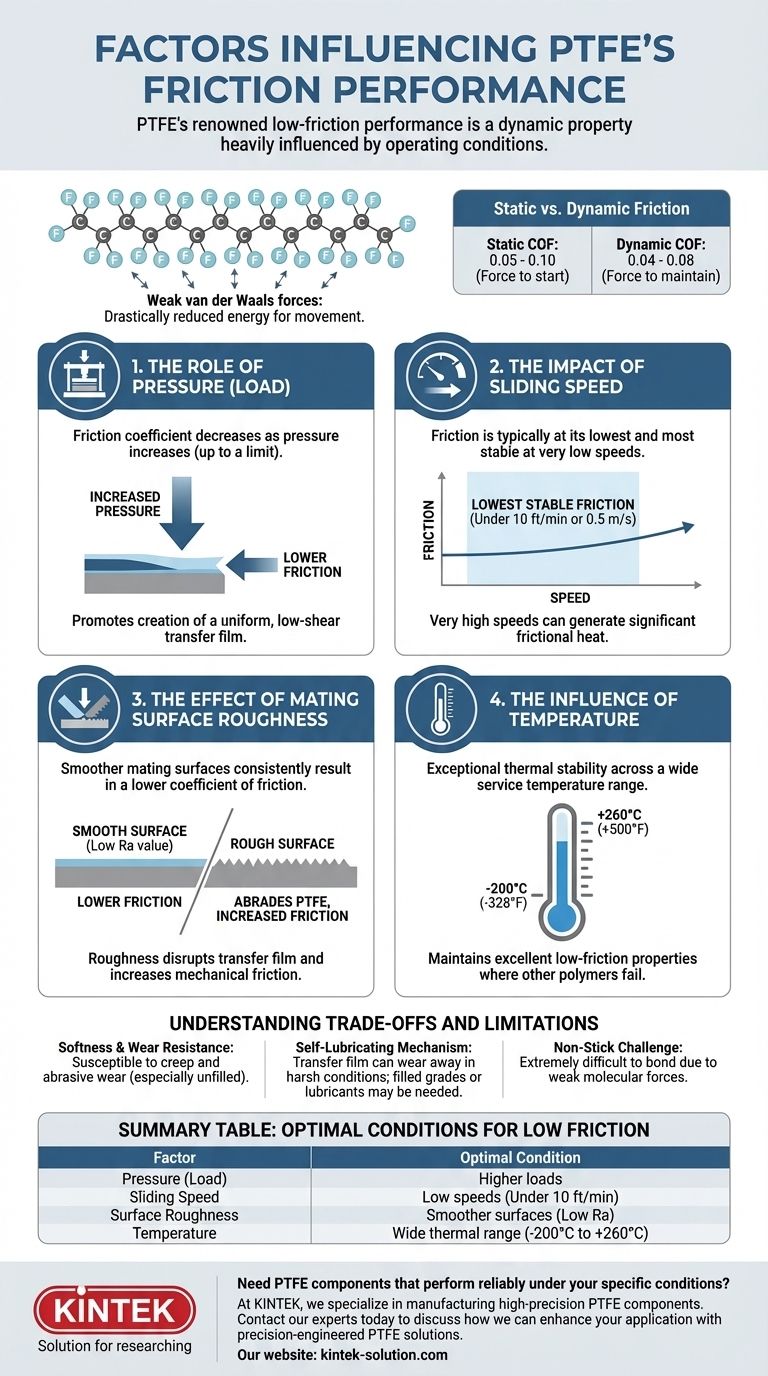

To be clear, Polytetrafluoroethylene (PTFE) does not have one single coefficient of friction. Its renowned low-friction performance is a dynamic property heavily influenced by operating conditions, including the applied pressure (load), sliding speed, mating surface roughness, and ambient temperature.

The core principle to understand is that PTFE's friction is not a static value but a variable outcome of the entire system it operates within. For optimal performance, PTFE generally favors higher pressures and lower sliding speeds, where it can establish a stable, low-shear transfer film.

The Foundation of PTFE's Low Friction

Before examining the external factors, it's essential to understand why PTFE is inherently slippery. Its unique properties are rooted in its molecular structure.

A Unique Molecular Structure

PTFE is composed of long chains of carbon atoms completely surrounded by fluorine atoms. This fluorine sheath shields the carbon backbone, resulting in extremely weak intermolecular forces of attraction, known as van der Waals forces.

Because these forces are so weak, other materials cannot easily "stick" to the PTFE surface, drastically reducing the energy required for movement.

Static vs. Dynamic Friction

It is critical to distinguish between the force needed to start movement (static friction) and the force needed to maintain it (dynamic friction).

For PTFE, the static coefficient of friction (COF) typically ranges from 0.05 to 0.10. The dynamic COF is often lower, ranging from 0.04 to 0.08, as a thin film of PTFE transfers to the mating surface during motion, creating a PTFE-on-PTFE interface.

Key Operating Factors Influencing Friction

The real-world performance of a PTFE component depends entirely on how it interacts with its environment. Four factors are paramount.

The Role of Pressure (Load)

Unlike many materials, PTFE's coefficient of friction tends to decrease as pressure increases, up to a certain limit.

High pressure helps to smooth the mating surfaces and promotes the creation of a uniform, low-shear transfer film, which is the key mechanism behind its low dynamic friction.

The Impact of Sliding Speed

Sliding speed has a complex relationship with friction. At very low speeds (under 10 ft/min or 0.5 m/s), friction is typically at its lowest and most stable.

As speed increases, the dynamic COF may rise slightly before stabilizing. However, very high speeds can generate significant frictional heat, which can affect the material's integrity.

The Effect of Mating Surface Roughness

The finish of the surface rubbing against the PTFE is critical. A smoother mating surface (lower Ra value) consistently results in a lower coefficient of friction.

A rough surface can abrade the soft PTFE, disrupting the transfer film and increasing the mechanical component of friction.

The Influence of Temperature

One of PTFE's most significant advantages is its exceptional thermal stability.

It maintains its excellent low-friction properties across an incredibly wide service temperature range, typically from -200°C to +260°C (-328°F to +500°F), outperforming almost any other polymer in this regard.

Understanding the Trade-offs and Limitations

While its low friction is remarkable, PTFE is not without its practical limitations. An effective design must account for its inherent trade-offs.

Softness and Wear Resistance

PTFE is a relatively soft material. This softness allows it to conform well to mating surfaces but also makes it susceptible to creep (deformation under sustained load) and abrasive wear, especially when unfilled.

The "Self-Lubricating" Mechanism

PTFE is considered self-lubricating because it transfers a film to the mating surface. However, this film can be worn away in abrasive or high-speed, high-load conditions.

In harsh environments, external lubricants may still be beneficial, or a filled grade of PTFE (containing glass, carbon, or other fillers) may be necessary to improve wear resistance.

The Non-Stick Challenge

The same weak molecular forces that give PTFE its low friction also make it extremely difficult to bond. This non-stick characteristic is an advantage for cookware but a significant design challenge when you need to glue or mechanically attach a PTFE component.

Making the Right Choice for Your Application

To leverage PTFE effectively, you must align your design with its inherent properties under your specific operating conditions.

- If your primary focus is low-friction bearings for high loads and slow speeds: Leverage the fact that increasing pressure generally lowers PTFE's COF.

- If your primary focus is minimizing start-up force (stiction): Design around PTFE's excellent low static COF, but ensure surfaces are smooth to achieve the best results.

- If your primary focus is performance in extreme temperatures: Rely on PTFE's unparalleled thermal stability, which ensures consistent frictional behavior where other polymers would fail.

- If your primary focus is durability in an abrasive system: Recognize that pure PTFE may wear quickly and consider using a filled grade of PTFE to enhance its mechanical strength and wear resistance.

Ultimately, treating PTFE's coefficient of friction as a dynamic system variable, rather than a fixed number, is the key to successful engineering design.

Summary Table:

| Factor | Influence on PTFE Friction | Optimal Condition |

|---|---|---|

| Pressure (Load) | Friction decreases as pressure increases | Higher loads |

| Sliding Speed | Friction is lowest at low speeds | Under 10 ft/min (0.5 m/s) |

| Surface Roughness | Smoother surfaces yield lower friction | Low Ra value (smooth) |

| Temperature | Maintains low friction from -200°C to +260°C | Wide thermal range |

Need PTFE components that perform reliably under your specific conditions?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your PTFE parts are optimized for your unique friction, load, and temperature requirements, from prototype to high-volume production.

Contact our experts today to discuss how we can enhance your application with precision-engineered PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications