The reliability of a PTFE lip seal is not accidental. It is the direct result of a systems-based engineering approach that combines advanced material science with mechanical precision. The four key elements are the specific geometry of the PTFE lip, the integrity of the static gasket seal, the precision of the steel casing, and a meticulously controlled forming process during manufacturing.

The core takeaway is that a PTFE lip seal's dependability doesn't come from the PTFE material alone. It's an engineered system where the unique properties of PTFE are harnessed by a precise mechanical design to create a robust seal for demanding applications where other materials would fail.

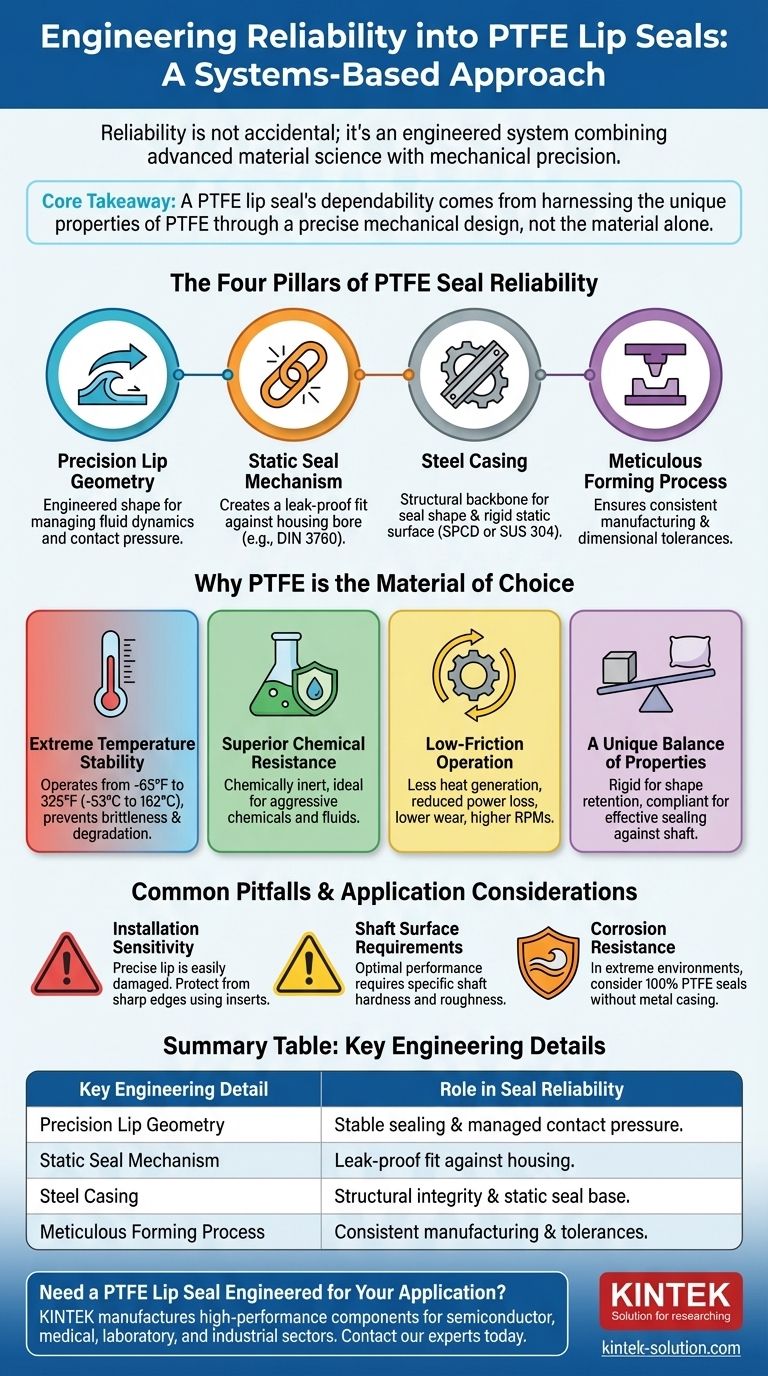

The Four Pillars of PTFE Seal Reliability

The consistent performance of these seals can be attributed to four interconnected design and manufacturing principles.

Precision Lip Geometry

The shape of the seal lip is not arbitrary. It is engineered to manage fluid dynamics and contact pressure against the shaft under various operating conditions, including high RPMs and pressures. This specific geometry ensures a stable and effective sealing line.

The Static Seal Mechanism

A lip seal creates two distinct seals. The primary, dynamic seal is formed by the PTFE lip against the rotating shaft. The second, static seal is formed between the seal's outer casing and the housing bore. This static seal's interference fit often adheres to strict standards like DIN 3760, ensuring a leak-proof path is prevented around the outside of the seal.

The Role of the Steel Casing

The casing provides the structural backbone for the seal. It ensures the seal retains its precise shape during installation and operation and provides the rigid surface necessary for the static seal against the housing. While mild steel (SPCD) is standard, options like stainless steel (JIS SUS 304) are available for applications requiring greater corrosion resistance.

The Meticulous Forming Process

A superior design is only effective if it can be manufactured consistently. The process of forming the seal, from molding the PTFE element to fixing it within the casing, is a critical control point. This ensures that every seal meets the required dimensional tolerances for reliable performance.

Why PTFE is the Material of Choice

The engineering principles above are built upon the inherent advantages of Polytetrafluoroethylene (PTFE) as a material.

Extreme Temperature Stability

PTFE can operate reliably across a vast temperature range, typically from -65°F to 325°F (-53°C to 162°C). This stability prevents the material from becoming brittle at low temperatures or degrading at high temperatures.

Superior Chemical Resistance

PTFE is one of the most chemically inert polymers available. This makes it the ideal choice for sealing applications involving aggressive chemicals or fluids that would quickly degrade traditional elastomeric seals.

Low-Friction Operation

A key advantage of PTFE is its extremely low coefficient of friction. This translates to less heat generation, reduced power loss, and lower wear on both the seal and the shaft, enabling it to perform reliably at higher surface speeds (RPMs).

A Unique Balance of Properties

PTFE strikes a unique balance between hardness and softness. It is rigid enough to hold its engineered shape under pressure but compliant enough to create an effective seal against the shaft surface.

Common Pitfalls and Application Considerations

While robust, the reliability of a PTFE lip seal is dependent on its correct application and handling.

Installation Sensitivity

The PTFE lip is precise and less flexible than traditional rubber seals. It can be easily damaged during installation. Protecting the seal lip from sharp edges on the shaft using plastic or cardboard inserts is a critical step to prevent premature failure.

Shaft Surface Requirements

The sealing dynamics of PTFE are different from elastomers. For optimal life and performance, the shaft's surface hardness and roughness must be within the manufacturer's specified range. An improper shaft finish can either accelerate seal wear or prevent the seal from functioning correctly.

Environments Demanding Maximum Corrosion Resistance

In highly corrosive applications, even a stainless steel casing can eventually degrade. For these ultimate-service scenarios, a 100% PTFE seal without any metal casing is an available option, ensuring total chemical inertness.

Making the Right Choice for Your Application

Selecting the right seal requires matching its engineered features to your primary operational challenge.

- If your primary focus is high-speed or high-pressure operation: The low-friction properties and precisely engineered lip geometry of PTFE seals are the key drivers of reliability.

- If your primary focus is chemical compatibility or extreme temperatures: The inherent stability of the PTFE material itself is the most critical factor for long-term performance.

- If your primary focus is reliability in a corrosive environment: Specify a seal with a stainless steel casing to prevent premature failure from rust while leveraging the benefits of the PTFE lip.

Understanding these interconnected engineering details allows you to confidently specify a seal designed for success in your most critical applications.

Summary Table:

| Key Engineering Detail | Role in Seal Reliability |

|---|---|

| Precision Lip Geometry | Manages fluid dynamics & contact pressure for stable sealing. |

| Static Seal Mechanism | Creates a leak-proof fit against the housing bore (e.g., per DIN 3760). |

| Steel Casing | Provides structural integrity and a rigid surface for the static seal. |

| Meticulous Forming Process | Ensures consistent manufacturing and adherence to tight tolerances. |

Need a PTFE Lip Seal Engineered for Your Demanding Application?

At KINTEK, we manufacture high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our commitment to precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a seal designed for reliability.

Contact our experts today to discuss your specific requirements and leverage our expertise in PTFE sealing solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications