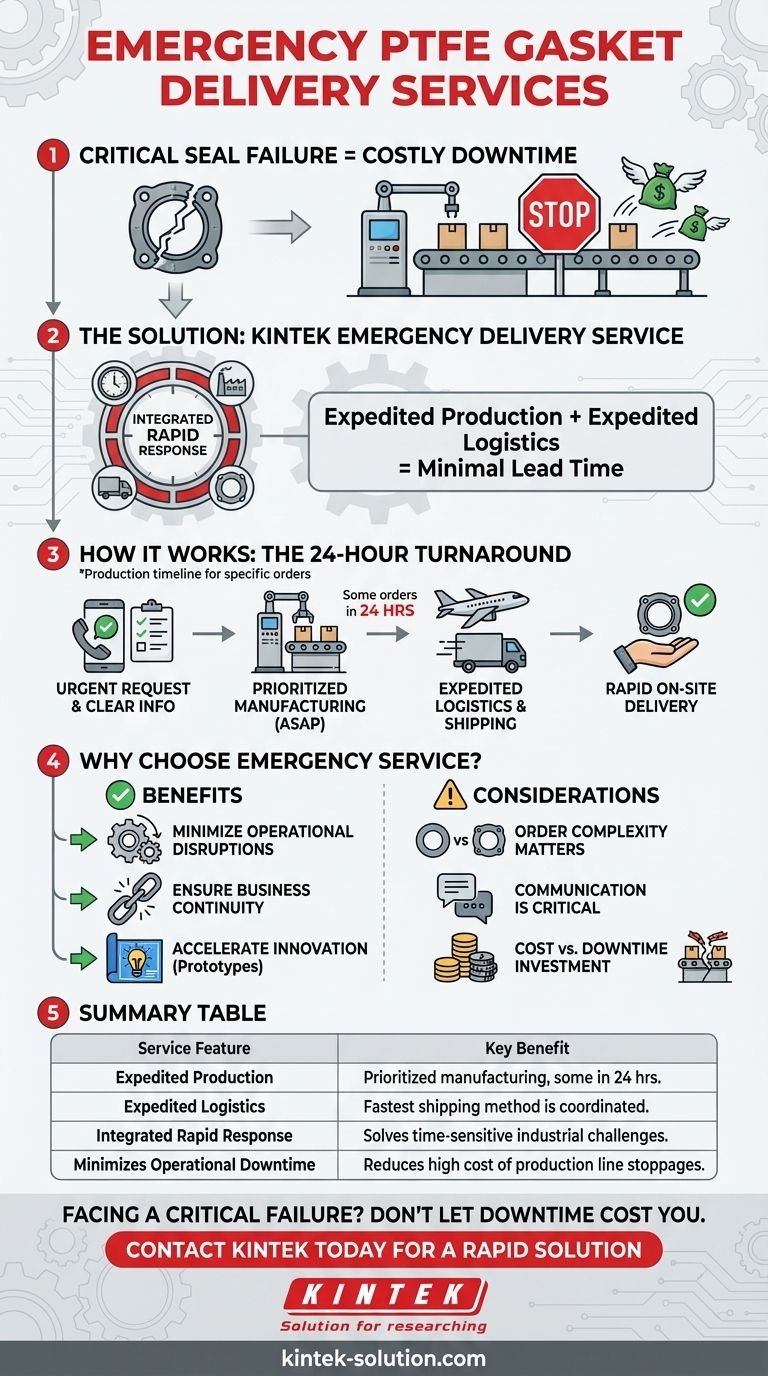

For urgent PTFE gasket orders, an Emergency Delivery Service is available. This specialized service is designed for critical situations, combining expedited production—with some orders manufactured in as little as 24 hours—with the fastest possible shipping to minimize operational downtime.

The key is to understand that this isn't just a faster shipping option; it's an integrated rapid response system that prioritizes your order from manufacturing to final delivery to solve time-sensitive industrial challenges.

Beyond Standard Shipping: Understanding Emergency Delivery

When a critical seal fails, the primary concern is not the cost of the replacement part, but the cost of the downtime. Standard supply chains are often too slow for these scenarios. This is the problem that specialized emergency services are built to solve.

What is an Emergency Service?

An Emergency Delivery Service is a premium offering that goes beyond simply putting a package on a faster truck. It triggers an internal process to prioritize your order's manufacturing slot, ensuring the gaskets are produced immediately.

This service coordinates expedited production with expedited logistics to create the shortest possible lead time from your initial request to having the part in hand.

The 24-Hour Turnaround

The claim of a 24-hour turnaround refers specifically to the production timeline for certain orders. This is a testament to highly efficient manufacturing capabilities designed for rapid response.

It's important to note that this timeline applies to the manufacturing of the gasket. The total delivery time will also include the subsequent shipping and transit period.

Why This Service Exists

The core purpose of this service is to minimize costly operational disruptions. In industrial settings, a single failed gasket can halt an entire production line, leading to significant financial losses.

This service acts as an insurance policy, providing a reliable way to get operations back online with minimal delay when facing an unexpected component failure.

Key Considerations for Emergency Orders

While incredibly valuable, utilizing an emergency service effectively requires a clear understanding of the process. It is a tool for specific, urgent situations.

Order Complexity Matters

The 24-hour production capability is most feasible for standard designs or those with readily available tooling. Highly custom or complex gaskets may require more time for manufacturing, even under an expedited schedule.

Communication is Critical

To meet aggressive timelines, your supplier needs clear and accurate information immediately. Be prepared to provide precise specifications, material requirements, and quantity needs upfront to avoid any delays in kicking off the production process.

Cost vs. Downtime

Emergency services carry a premium cost compared to standard orders. However, this increased cost is almost always negligible when weighed against the significant expense of prolonged equipment downtime. The decision should be framed as an investment in operational continuity.

Making the Right Choice for Your Situation

To ensure a successful outcome, align the service with your specific operational need.

- If you are facing an unexpected critical failure: The Emergency Delivery Service is the correct choice to mitigate downtime and restore operations as quickly as possible.

- If you are planning for scheduled maintenance with a tight deadline: This service can guarantee that necessary components arrive precisely when needed, preventing project delays.

- If you need a rapid prototype for testing: Leveraging an expedited service can significantly shorten your design and validation cycle, accelerating innovation.

Ultimately, this service provides a critical capability for maintaining operational resilience in demanding industrial environments.

Summary Table:

| Service Feature | Key Benefit |

|---|---|

| Expedited Production | Prioritized manufacturing, with some orders completed in 24 hours. |

| Expedited Logistics | Fastest possible shipping method is coordinated. |

| Integrated Rapid Response | Solves time-sensitive industrial challenges from order to delivery. |

| Minimizes Operational Downtime | Reduces the high cost of production line stoppages. |

Facing a critical seal failure? Don't let downtime cost you.

KINTEK specializes in rapid-response manufacturing of high-quality PTFE components, including seals, gaskets, liners, and labware. Our emergency delivery service is designed for semiconductor, medical, laboratory, and industrial customers who need to restore operations immediately.

We combine precision production with custom fabrication—from prototypes to high-volume orders—to get you the exact part you need, fast.

Contact KINTEK today to discuss your urgent PTFE gasket requirements and get a rapid solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are important tips for turning PTFE on a lathe? Achieve a Clean, Precise Cut Every Time

- How do PTFE bushes compare to traditional metal bushings? Choose the Right Bushing for Your Application

- What is the purpose of dimples on the PTFE surface of these bearings? Enhancing Lubrication and Longevity

- How should PTFE-lined valves be maintained for optimal performance? Ensure Long-Term Reliability & Prevent Costly Downtime

- How are PTFE rubber seals constructed? Precision Engineering for High-Performance Sealing

- What makes PTFE expansion bellows suitable for aerospace applications? Unmatched Reliability in Extreme Environments

- What are the benefits and drawbacks of PTFE Lined Plug Valves? Weighing Corrosion Resistance vs. Operational Demands

- What are some tips for successfully machining PTFE? Master Precision Cuts for Soft, Heat-Sensitive Material