The fundamental difference between PTFE and traditional metal bushings lies in their core properties and ideal use cases. PTFE (Polytetrafluoroethylene) excels in applications requiring self-lubrication, chemical resistance, and low friction, while metal bushings are the standard for high-load, high-impact, and high-temperature scenarios where mechanical strength is paramount.

The decision is not about which material is universally superior, but which one possesses the specific characteristics required by your application's operational environment and performance demands.

The Core Advantages of PTFE Bushes

PTFE's unique molecular structure gives it a distinct set of advantages, making it the ideal choice for specific engineering challenges.

Exceptionally Low Friction

PTFE boasts one of the lowest coefficients of friction of any solid material. This allows for smooth, quiet, and efficient movement between parts.

Crucially, these bushes are self-lubricating. They require no external grease or oil, which eliminates maintenance schedules and prevents the contamination that lubricants can attract.

Unmatched Chemical & Corrosion Resistance

PTFE is chemically inert, meaning it does not react with most chemicals, acids, or bases. This makes it invaluable in corrosive or sanitary environments, such as food processing or chemical manufacturing, where a metal bushing would quickly degrade.

Unlike metal, PTFE is impervious to rust and other forms of corrosion caused by moisture.

Wide Operational Temperature Range

PTFE bushes perform reliably across an impressive temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F). This tolerance allows them to be used in both cryogenic and high-heat applications where many other materials would fail.

Excellent Electrical Insulation

As a polymer, PTFE is an outstanding electrical insulator. This property is critical in applications where the bushing must prevent electrical current from passing between components, a task a metal bushing cannot perform.

Where Metal Bushings Remain Essential

Despite PTFE's benefits, the inherent strength and stability of metal make it the only viable option in many demanding industrial applications.

Superior Load Capacity

The primary advantage of metal (such as bronze, steel, or brass) is its high mechanical strength and rigidity. Metal bushings can withstand immense static and dynamic loads, high pressures, and significant impact forces that would cause a PTFE bushing to deform or fail.

Higher Temperature Ceilings

While PTFE's temperature range is broad, certain metal alloys can operate reliably at temperatures far exceeding PTFE's 260°C limit. In engines, furnaces, or other extreme-heat machinery, metal is the default choice.

Dimensional Stability

Metals are less susceptible to "creep," the tendency of a material to deform over time under a constant load. They also have a lower coefficient of thermal expansion, meaning they maintain their shape and tolerances more consistently during temperature fluctuations.

Understanding the Trade-offs

Choosing between these materials requires a clear understanding of the compromises involved, balancing upfront costs against long-term performance and reliability.

Cost vs. Total Cost of Ownership

PTFE bushes often have a higher initial purchase price than standard metal bushings.

However, their self-lubricating nature eliminates the cost of lubricants and the labor required for maintenance. In the right application, their longer service life can result in a lower total cost of ownership.

Mechanical Strength vs. Environmental Resistance

This is the central trade-off. Metal provides the raw strength and hardness needed for heavy-duty mechanical work. PTFE provides unparalleled resistance to chemical attack and friction without the need for maintenance.

Precision vs. Material Properties

Metal bushings can often be machined to tighter tolerances, which is critical for high-precision equipment. PTFE's relative softness and higher thermal expansion must be accounted for in designs requiring minimal clearance changes.

Making the Right Choice for Your Application

To select the correct bushing, you must prioritize the most critical demand of your specific system.

- If your primary focus is maintenance-free operation in a corrosive or sanitary environment: PTFE is the clear choice for its self-lubricating and chemically inert nature.

- If your primary focus is handling extremely high loads, high pressures, or significant impact: A traditional metal bushing (like steel or bronze) is necessary for its superior mechanical strength.

- If your application requires smooth, quiet, low-friction movement and electrical insulation: PTFE's inherent properties make it the ideal solution.

- If you are operating at temperatures consistently above 260°C (500°F): A specialized high-temperature metal alloy bushing is the only appropriate selection.

By aligning the material's inherent strengths with your application's specific demands, you ensure optimal performance, reliability, and service life.

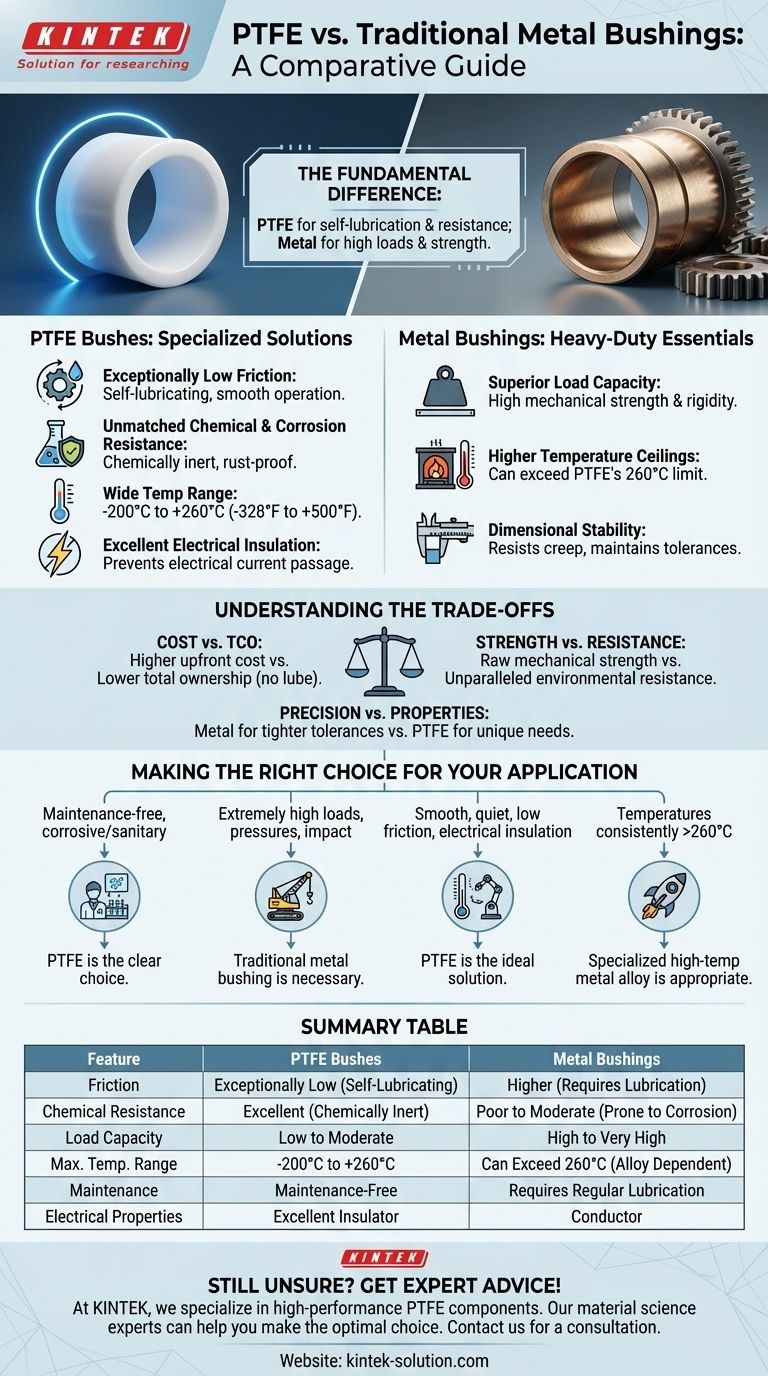

Summary Table:

| Feature | PTFE Bushes | Metal Bushings |

|---|---|---|

| Friction | Exceptionally Low (Self-Lubricating) | Higher (Requires Lubrication) |

| Chemical Resistance | Excellent (Chemically Inert) | Poor to Moderate (Prone to Corrosion) |

| Load Capacity | Low to Moderate | High to Very High |

| Max. Temp. Range | -200°C to +260°C | Can Exceed 260°C (Alloy Dependent) |

| Maintenance | Maintenance-Free | Requires Regular Lubrication |

| Electrical Properties | Excellent Insulator | Conductor |

Still Unsure Which Bushing is Right for Your Project?

At KINTEK, we specialize in manufacturing high-performance PTFE components like seals, liners, and custom bushings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a component perfectly tailored to your application's demands for friction, chemical resistance, and temperature.

Let our material science experts help you make the optimal choice. Contact us today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability