PTFE rubber seals are advanced composite components created by bonding a precision-engineered Polytetrafluoroethylene (PTFE) element to a flexible rubber elastomer. This multi-material construction is not a simple mixture but a deliberate engineering process designed to leverage the distinct advantages of each material.

The core principle behind a PTFE rubber seal's construction is to combine the unparalleled low-friction and chemical resistance of a PTFE contact face with the flexibility and constant sealing force provided by a rubber energizer. This creates a high-performance seal that overcomes the limitations of single-material designs.

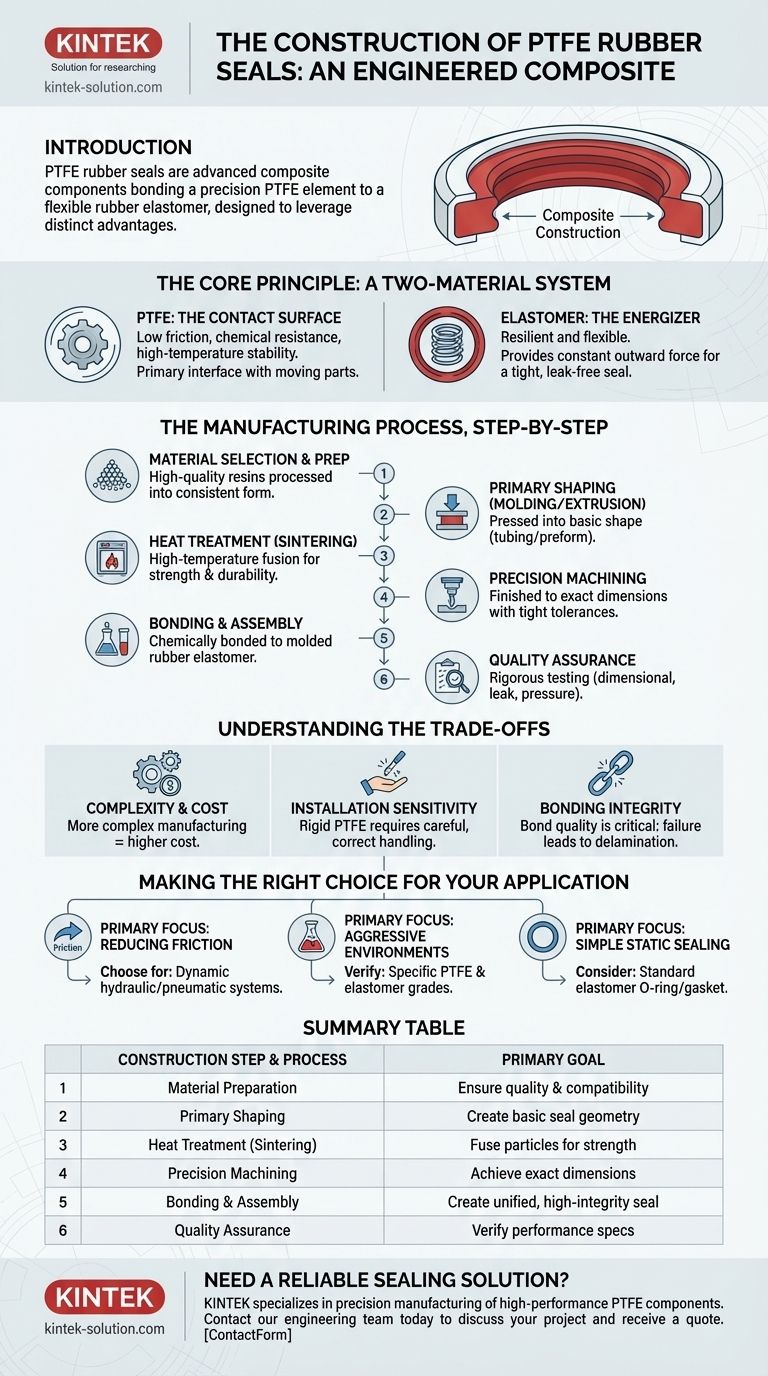

The Core Principle: A Two-Material System

To understand the construction, you must first understand the purpose of each component. The seal is an engineered system where two materials perform separate but complementary jobs.

The Role of PTFE: The Contact Surface

The PTFE component is the seal's primary interface with the moving part. Its role is defined by its inherent material properties: extremely low friction (lubricity), broad chemical resistance, and high-temperature stability. This makes it the ideal material for dynamic applications where wear and stick-slip are major concerns.

The Role of the Elastomer: The Energizer

The rubber element acts as a spring or "energizer." While PTFE is relatively rigid, the elastomer (such as FKM, EPDM, or HNBR) is resilient and flexible. It provides the constant outward force needed to press the PTFE lip against the sealing surface, ensuring a tight, leak-free seal even with minor surface imperfections or pressure fluctuations.

The Manufacturing Process, Step-by-Step

Creating a reliable PTFE rubber seal involves a precise, multi-stage manufacturing process that goes far beyond simply molding rubber.

Step 1: Material Selection and Preparation

The process begins with selecting high-quality PTFE resins. These are processed into a consistent granular or powdered form, which is critical for the uniformity of the final product.

Step 2: Primary Shaping

The prepared PTFE material is then pressed into a basic shape, typically tubing or a "preform," using methods like molding or extrusion. This creates the rough geometry of the final PTFE element.

Step 3: Heat Treatment (Sintering)

This is a critical thermal process where the shaped PTFE is heated to high temperatures. This step, also known as curing or frittage, fuses the PTFE particles together, locking in the material's mechanical strength, durability, and chemical resistance.

Step 4: Precision Machining

After sintering, the hardened PTFE preform is finished to its exact final dimensions. This is done using specialized CNC machining with cutting tools and lubricants designed specifically for PTFE to achieve tight tolerances and a smooth surface finish.

Step 5: Bonding and Assembly

The finished PTFE component is then chemically bonded to the molded rubber elastomer. This bonding process is proprietary and crucial to the seal's integrity, as it must withstand the forces and environmental conditions of the application.

Step 6: Quality Assurance

Finally, each seal undergoes rigorous testing. This often includes dimensional verification as well as functional checks like leak and pressure tests to ensure it meets all performance specifications before it is ready for use.

Understanding the Trade-offs

The sophisticated construction of PTFE seals provides significant benefits, but it also introduces specific considerations.

Complexity and Cost

The multi-step manufacturing process, involving precision machining and advanced bonding techniques, makes PTFE seals inherently more complex and costly to produce than simple, single-piece elastomer seals.

Installation Sensitivity

The rigid nature of the PTFE lip makes these seals less forgiving during installation. Unlike a pliable rubber seal, a PTFE seal can be scratched or permanently deformed by improper handling, emphasizing the need for correct tools and procedures.

Bonding Integrity

The bond between the PTFE and the rubber is a potential point of failure if not executed to the highest quality standards. A compromised bond can lead to delamination and premature seal failure, making manufacturer quality a critical selection factor.

Making the Right Choice for Your Application

Understanding the construction process helps you select the right seal based on your primary engineering goal.

- If your primary focus is reducing friction and preventing stick-slip: The machined PTFE contact surface is the key feature, making it the superior choice for dynamic hydraulic or pneumatic systems.

- If your primary focus is aggressive chemical or high-temperature environments: The specific grades of PTFE and the elastomer (like FKM) used in construction are the critical factors to verify with the manufacturer.

- If your primary focus is simple, cost-effective static sealing: The complexity of a PTFE seal is unnecessary, and a standard, single-material elastomer O-ring or gasket is often the more appropriate solution.

By appreciating how these components are engineered, you can confidently specify them for the demanding applications they were designed to solve.

Summary Table:

| Construction Step | Key Process | Primary Goal |

|---|---|---|

| Material Preparation | Selecting PTFE resins & elastomers | Ensure material quality and compatibility |

| Primary Shaping | Molding or extrusion of PTFE | Create the basic seal geometry |

| Heat Treatment | Sintering (curing) the PTFE | Fuse particles for strength and durability |

| Precision Machining | CNC machining of PTFE | Achieve exact dimensions and smooth finish |

| Bonding & Assembly | Chemically bonding PTFE to rubber | Create a unified, high-integrity seal |

| Quality Assurance | Dimensional and pressure testing | Verify performance meets specifications |

Need a reliable sealing solution for a demanding application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including seals, liners, and labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal that is perfectly engineered for your specific requirements in the semiconductor, medical, laboratory, or industrial sectors.

We understand that the integrity of the PTFE-to-rubber bond is critical to your system's performance. Let us provide you with a seal built for durability, chemical resistance, and low friction.

Contact our engineering team today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does a PTFE Lined Plug Valve work? A Guide to Superior Corrosion Resistance

- In which industries are EPTFE gaskets commonly used? Critical Sealing Solutions for Demanding Environments

- What types of contaminants should be avoided with PTFE-lined bearings? Protect Your Investment and Maximize Performance

- How does the compressibility of ePTFE gaskets benefit sealing applications? Achieve Superior, Leak-Free Seals

- How are PTFE gaskets used in the petroleum and chemical industry? Ensure Leak-Proof Sealing in Harsh Environments

- What are the tensile strength and elongation properties of PTFE O-rings? Key Metrics for Demanding Seals

- How are PTFE coated fasteners beneficial in the automotive sector? Enhance Reliability and Simplify Maintenance

- Why are PTFE sheets used in the medical industry? For Biocompatibility, Inertness & Low Friction