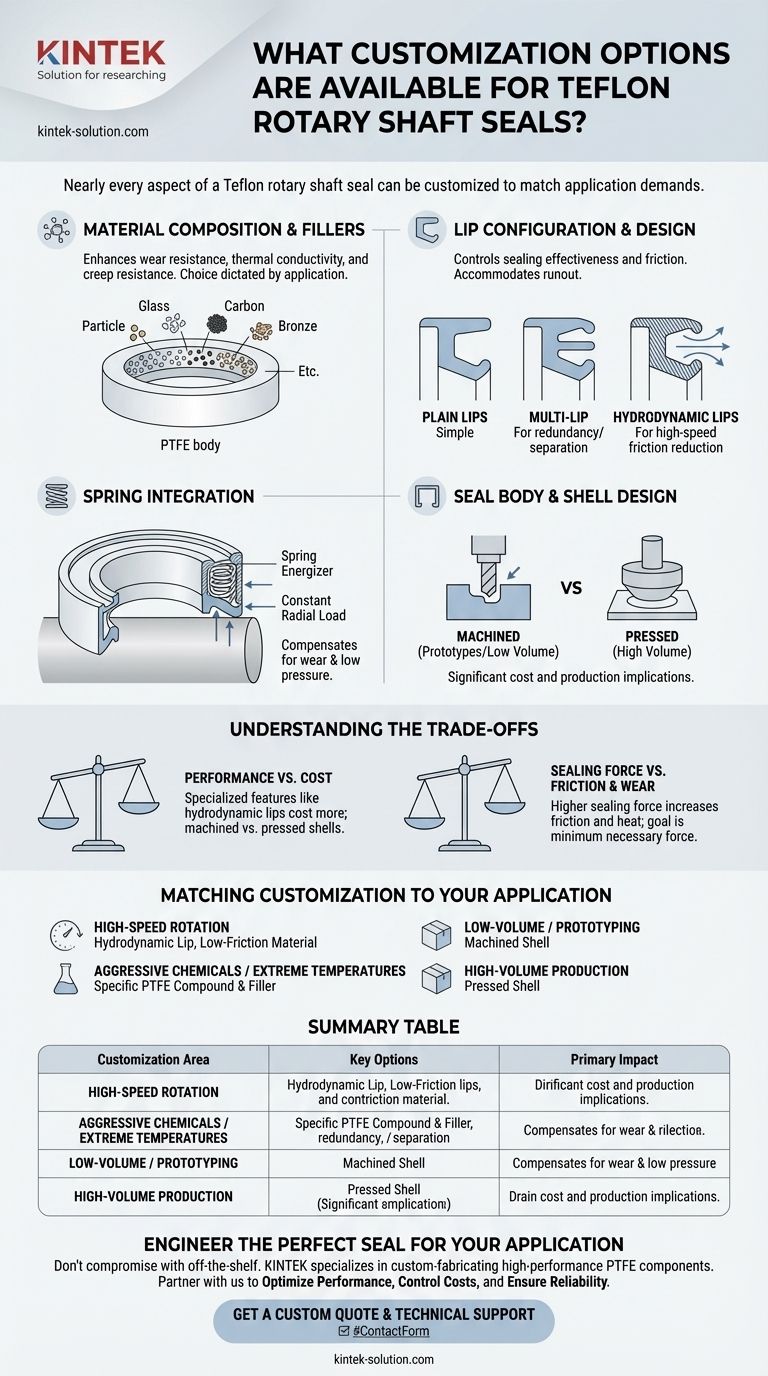

In short, nearly every aspect of a Teflon rotary shaft seal can be customized. Manufacturers can modify the seal's physical dimensions, lip configuration, material composition with specific fillers, and spring energizer to precisely match the demands of an application, from aerospace to chemical processing.

The core principle is that customization goes far beyond simple sizing. It is about fundamentally engineering the seal's performance characteristics—like wear resistance, chemical compatibility, and sealing pressure—to ensure reliability and longevity in a specific operational environment.

Core Customization Areas: Beyond Basic Dimensions

To select the right seal, you must understand how each customizable element impacts its function. The key is to see the seal not as a single part, but as a system of components working together.

Material Composition and Fillers

The base PTFE (Teflon) material is rarely used in its pure form for dynamic seals. Its properties are enhanced by adding fillers.

These fillers are blended with the PTFE to improve specific characteristics like wear resistance, thermal conductivity, and resistance to deformation under load (creep). The choice of filler is dictated entirely by the application's demands.

Lip Configuration and Design

The seal's lip is the most critical element for performance. Its design directly controls the sealing effectiveness and frictional properties.

Common configurations include:

- Plain Lips: A straightforward design for general-purpose sealing.

- Multi-Lip: Uses two or more lips for redundancy, often to separate different media or provide an extra barrier against contaminants.

- Hydrodynamic Lips: Feature microscopic patterns on the lip that actively pump fluid away from the sealing edge during rotation. This is critical for reducing friction and heat in high-speed applications.

The flexibility of the lip design also helps accommodate shaft runout or misalignment, ensuring a consistent seal even under less-than-ideal mechanical conditions.

Spring Integration

A spring energizer, typically made of metal, is often integrated into the seal jacket. Its purpose is to provide a constant, uniform radial load on the shaft.

This ensures a tight seal at very low pressures when system pressure is insufficient to activate the lip. It also compensates for material wear over the seal's lifetime, extending its effective service life.

Seal Body and Shell Design

The method used to construct the seal's body, or shell, has significant cost and production implications.

For low-volume production or prototyping, shells can be machined. This avoids high initial tooling charges, making it cost-effective for custom or small-batch orders.

For high-volume production, shells are pressed or stamped. While this requires a significant upfront investment in tooling, it drastically reduces the unit cost for large quantities.

Understanding the Trade-offs

Customization is not about choosing the "best" features, but about balancing competing requirements. Every design choice involves a trade-off.

Performance vs. Cost

Highly specialized features like hydrodynamic lips, exotic fillers, or complex multi-lip designs deliver superior performance in extreme conditions. However, this increased capability comes with a higher unit cost.

Similarly, machined shells are ideal for avoiding tooling costs on prototypes, but pressed shells are far more economical for mass production.

Sealing Force vs. Friction and Wear

A more aggressive seal design—for instance, one with a stronger spring or multiple lips—creates a tighter seal. This is excellent for preventing leaks but also increases friction.

Higher friction generates more heat, accelerates wear on both the seal and the shaft, and increases the energy required to turn the shaft. The goal is always to use just enough sealing force to meet requirements and no more.

Matching Customization to Your Application

Use your primary operational challenge to guide your customization choices.

- If your primary focus is high-speed rotation: Prioritize a hydrodynamic lip design and a low-friction material compound to manage heat and prevent premature wear.

- If your primary focus is aggressive chemicals or extreme temperatures: Concentrate on the material selection, choosing a PTFE compound and filler known for compatibility with your specific environment.

- If your primary focus is low-volume prototyping or custom fitting: Specify a machined shell to maintain flexibility and avoid expensive, dedicated tooling.

- If your primary focus is high-volume production and cost control: Work with a manufacturer to design for a pressed shell to minimize the per-unit cost over the long term.

Ultimately, leveraging these customization options allows you to engineer a seal that becomes a reliable, integrated part of your system.

Summary Table:

| Customization Area | Key Options | Primary Impact |

|---|---|---|

| Material & Fillers | Glass, carbon, bronze, etc. | Chemical resistance, wear, thermal properties |

| Lip Configuration | Plain, multi-lip, hydrodynamic | Sealing effectiveness, friction, speed capability |

| Spring Energizer | Type, load | Low-pressure sealing, wear compensation |

| Seal Body/Shell | Machined (prototypes) vs. Pressed (volume) | Unit cost, lead time, production volume |

Engineer the Perfect Seal for Your Application

Don't compromise with an off-the-shelf solution. KINTEK specializes in custom-fabricating high-performance PTFE components, including rotary shaft seals, for the semiconductor, medical, laboratory, and industrial sectors.

We partner with you to:

- Optimize Performance: Select the ideal material fillers, lip design, and spring for your specific speed, chemical, and temperature requirements.

- Control Costs: Choose between machined prototypes for flexibility or pressed shells for high-volume economy.

- Ensure Reliability: Achieve precise sealing that enhances the longevity and efficiency of your equipment.

Contact us today to discuss your project requirements and receive expert guidance. Let's build a seal that is precisely engineered for your success.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments