At its core, customizing a PTFE wear strip or band involves three primary levers: selecting the right material composition, defining precise physical dimensions, and choosing the final supply format. These options allow for the engineering of components that move beyond a generic part to become a solution tailored to a specific mechanical or chemical environment.

The most critical takeaway is that PTFE wear strip customization is not just about size. The ability to select specific material fillers (like carbon or bronze) is what allows you to fundamentally alter the performance characteristics of the component—such as wear resistance, compressive strength, and thermal conductivity—to match your exact application demands.

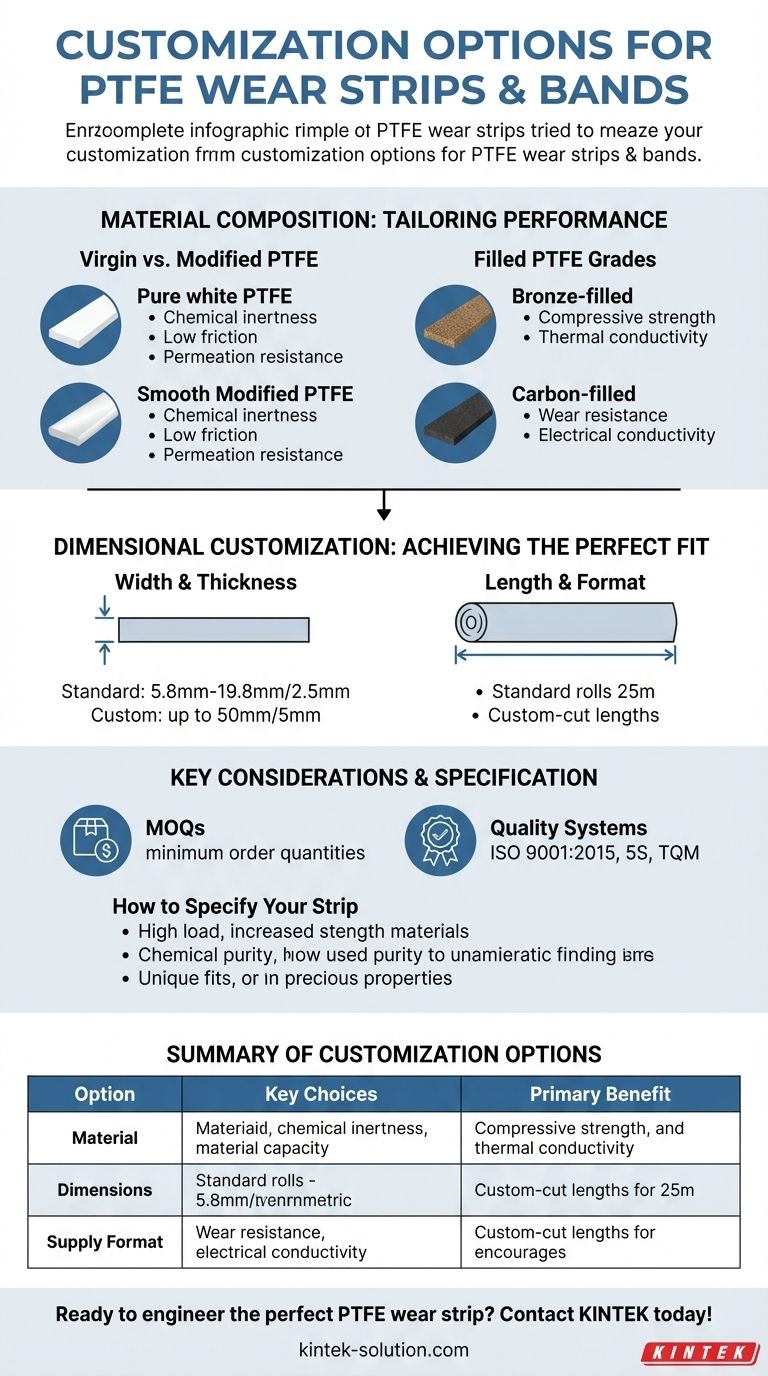

Material Composition: Tailoring Performance

The choice of PTFE material is the most significant customization you can make, as it directly dictates the component's functional properties.

Virgin vs. Modified PTFE

Virgin PTFE is the baseline material, offering excellent chemical inertness and a very low coefficient of friction. It is ideal for applications where purity is paramount.

Chemically Modified PTFE is an enhanced version that offers improved resistance to permeation and a smoother surface finish, while retaining the core benefits of virgin PTFE.

Filled PTFE Grades

Fillers are added to the PTFE base to dramatically enhance specific mechanical properties. This is where performance engineering truly happens.

Bronze Filled PTFE significantly increases compressive strength and thermal conductivity, making it suitable for applications with higher loads and speeds where heat dissipation is important.

Carbon Filled PTFE provides excellent wear resistance and good compressive strength. It is also electrically conductive, which can be a key feature for dissipating static charge.

Other filled grades are also available, allowing for a wide range of property modifications to meet unique operational challenges.

Dimensional Customization: Achieving the Perfect Fit

Once the material is selected, the physical form of the strip can be precisely defined to integrate perfectly into your assembly.

Width and Thickness

Standard widths often include sizes like 5.8 mm, 9.5 mm, and 19.8 mm, typically with a standard thickness of 2.5 mm.

However, non-standard sizes are widely available. Widths can be produced up to 50 mm and thickness up to 5 mm, all manufactured to strict tolerances for a precise fit.

Length and Format

The most common formats are standard rolls, often supplied in 25-meter lengths for high-volume use or for customers who prefer to cut their own lengths on-site.

For applications requiring exact dimensions out of the box, strips can be custom-cut to a specific length, reducing waste and saving assembly time.

Understanding the Trade-offs and Constraints

While customization offers significant advantages, it's important to understand the associated practical considerations.

Minimum Order Quantities (MOQs)

Requesting a custom size or a special material blend is often subject to a minimum order quantity. This is a standard manufacturing constraint to justify the setup of a custom production run.

The Importance of Quality Systems

The ability to deliver a custom part consistently relies on a robust quality management system. A manufacturer certified under ISO 9001:2015 demonstrates a commitment to process control from raw material input to the final product.

Modern engineering concepts like 5S and TQM are further indicators of a manufacturer's dedication to continuous improvement, ensuring that your custom components meet specifications every time.

How to Specify Your PTFE Wear Strip

To select the right options, start by defining your primary operational goal.

- If your primary focus is high load and wear resistance: Specify a bronze or carbon-filled PTFE to gain the necessary compressive strength and durability.

- If your primary focus is chemical purity and low friction: Choose virgin or chemically modified PTFE for its inertness and slick surface.

- If your primary focus is a unique component fit: Provide precise drawings with dimensions and tolerances, but be prepared for potential minimum order quantities.

Understanding these customization options empowers you to source a component that is perfectly engineered for its intended function.

Summary Table:

| Customization Option | Key Choices | Primary Benefit |

|---|---|---|

| Material Composition | Virgin PTFE, Chemically Modified, Bronze Filled, Carbon Filled | Tailors wear resistance, compressive strength, and chemical inertness |

| Dimensions | Custom width (up to 50mm), thickness (up to 5mm), and length | Ensures a perfect fit for your specific assembly requirements |

| Supply Format | Standard rolls (e.g., 25m) or custom-cut lengths | Optimizes for high-volume use or precise, ready-to-install parts |

Ready to engineer the perfect PTFE wear strip for your application?

At KINTEK, we specialize in custom PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our precision manufacturing and ISO 9001:2015 certified quality systems ensure your custom PTFE wear strips or bands—whether virgin, bronze-filled, or carbon-filled—meet exact specifications for wear resistance, load capacity, and chemical compatibility. From prototypes to high-volume orders, we deliver tailored solutions that enhance performance and durability.

Contact us today at #ContactForm to discuss your project requirements and receive a customized quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech