Machining Teflon (PTFE) is deceptively complex. The primary challenges stem from its inherent softness, extremely low thermal conductivity, and high coefficient of thermal expansion. These properties lead to issues with heat buildup, material deformation, and difficulty holding tight tolerances. Success requires a specific approach using extremely sharp tools, low cutting speeds, aggressive cooling, and precise workholding to manage the material's instability.

The core challenge of machining Teflon is not its hardness, but its inherent instability. Success depends less on aggressive material removal and more on managing heat, pressure, and thermal expansion to prevent the material from deforming or "moving" during and after the cutting process.

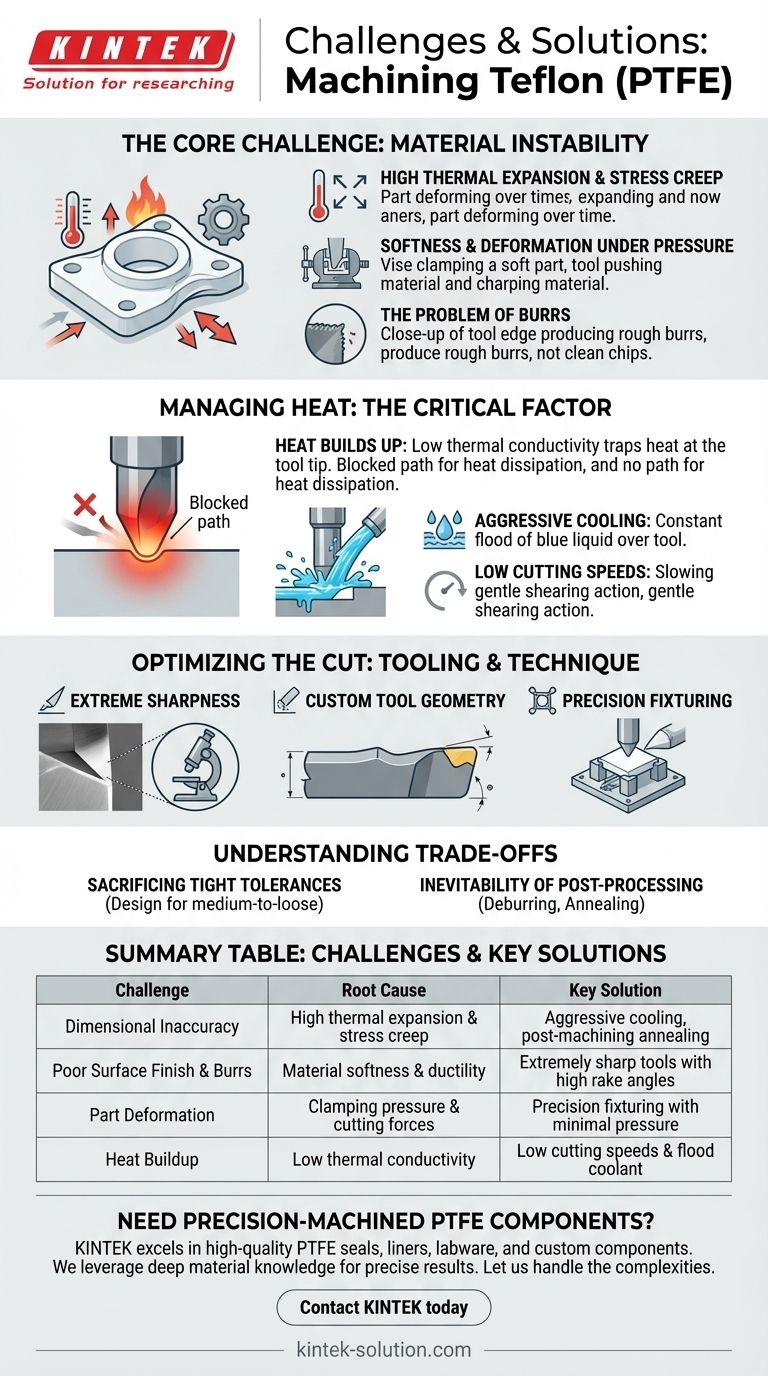

The Core Challenge: Material Instability

Teflon does not behave like metal or even most other plastics. Its primary challenges are rooted in its tendency to change shape under thermal and mechanical stress.

High Thermal Expansion and Stress Creep

Teflon expands and contracts significantly with temperature changes. This high coefficient of expansion makes holding tight tolerances incredibly difficult, as a part can be in-spec on a cool machine and out-of-spec at room temperature.

Furthermore, Teflon is subject to stress creep, meaning it will slowly deform over time when under pressure, even from its own internal stresses induced during manufacturing.

Softness and Deformation Under Pressure

The material's softness means it can easily be compressed or distorted by clamping forces in a vise or fixture. Overtightening will ruin the part before a single cut is made.

This softness also means the cutting tool can push the material away rather than shearing it cleanly, leading to dimensional inaccuracies and poor surface finishes.

The Problem of Burrs

Instead of producing a clean chip that breaks away, Teflon's soft, ductile nature often results in a persistent burr along the cut edge. This requires a dedicated post-processing step for removal, which must be planned for in advance.

Managing Heat: The Critical Factor

The single greatest enemy when machining Teflon is heat. Because the material is an excellent thermal insulator, heat generated by the cutting process becomes trapped at the tool tip instead of dissipating through the workpiece.

Why Heat Builds Up

Teflon's low thermal conductivity means it cannot effectively carry heat away from the cutting zone. This localized heat buildup can cause the material to melt, gum up the tool, or expand unpredictably, destroying any hope of accuracy.

The Role of Aggressive Cooling

To combat heat buildup, a liberal application of coolant is essential. A constant flood of water-soluble coolant is standard practice to pull heat away from the tool and the workpiece as quickly as it is generated.

The Impact of Cutting Speeds

Lower cutting speeds are mandatory. High speeds generate friction and heat faster than it can be removed, leading to the problems described above. The goal is a gentle, controlled shearing action.

Optimizing the Cut: Tooling and Technique

Standard metalworking tools and techniques are often ineffective on Teflon. The entire cutting strategy must be adapted to the material's unique properties.

The Mandate for Extreme Sharpness

Tools must be exceptionally sharp with a polished cutting edge. A dull or even standard tool will tend to plow through or push the material, causing it to deform and tear. Sharp carbide tools are a good baseline, with diamond-coated tools offering superior performance for high-precision work.

Custom Tool Geometry

Special tool geometries are often required. High positive rake angles and increased clearance angles help create a clean slicing action and prevent the soft material from sticking or rubbing against the tool, which would generate more heat.

Precision Fixturing

Workholding must be precise and delicate. Fixtures should be designed to support the workpiece securely without applying excessive clamping pressure that could cause distortion.

Understanding the Trade-offs and Limitations

To machine Teflon successfully, you must accept its inherent limitations and design around them.

Sacrificing Tight Tolerances

Whenever possible, design parts with medium-to-loose tolerances. If your application does not absolutely require micron-level precision, do not specify it. This provides a greater margin for error to account for thermal expansion and creep.

The Inevitability of Post-Processing

Assume that some form of post-processing will be necessary. This often includes a dedicated deburring step, which can involve manual trimming, light sanding, or even freezing the part to make the burrs brittle and easier to remove.

For high-precision applications, a post-machining annealing or stress-relieving cycle may be required to improve the part's long-term dimensional stability.

Making the Right Choice for Your Project

Your machining strategy should be dictated by the final requirements of the part.

- If your primary focus is achieving tight tolerances: Prioritize aggressive cooling and low cutting speeds, and plan for a post-machining annealing process to ensure long-term stability.

- If your primary focus is a smooth, burr-free surface finish: Use extremely sharp, polished tools with high positive rake angles and incorporate a specific deburring strategy into your production plan.

- If your primary focus is minimizing part deformation: Design fixtures that provide broad support with minimal clamping pressure and use low feed rates to avoid pushing the material.

Ultimately, success with Teflon comes from respecting its unique properties rather than fighting them.

Summary Table:

| Challenge | Root Cause | Key Solution |

|---|---|---|

| Dimensional Inaccuracy | High thermal expansion & stress creep | Aggressive cooling, post-machining annealing |

| Poor Surface Finish & Burrs | Material softness & ductility | Extremely sharp tools with high rake angles |

| Part Deformation | Clamping pressure & cutting forces | Precision fixturing with minimal pressure |

| Heat Buildup | Low thermal conductivity | Low cutting speeds & flood coolant |

Need Precision-Machined PTFE Components?

Machining Teflon requires specialized expertise to overcome its unique challenges. KINTEK excels at producing high-quality PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors.

We leverage our deep material knowledge and precision production capabilities—from prototypes to high-volume orders—to ensure your parts meet exact specifications without deformation or thermal issues.

Let us handle the complexities for you. Contact KINTEB today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech