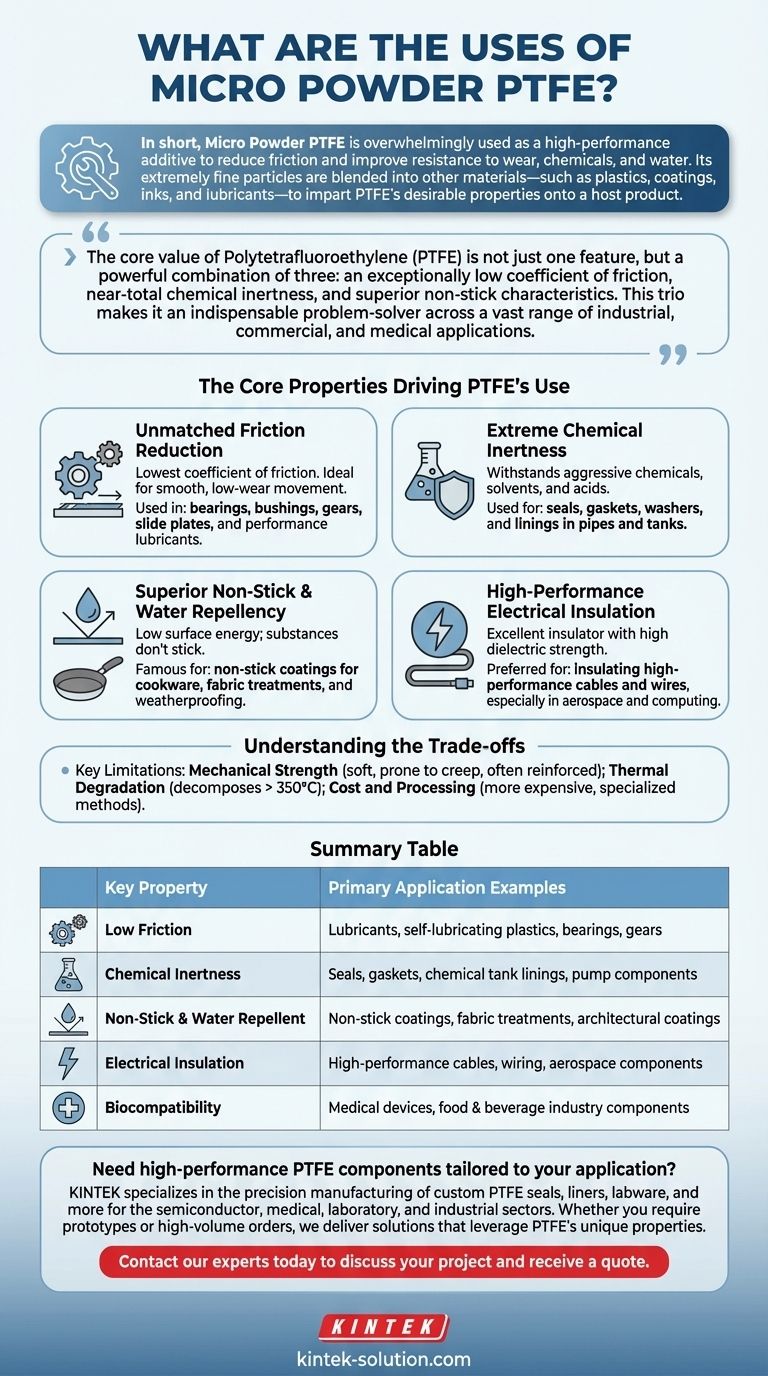

In short, Micro Powder PTFE is overwhelmingly used as a high-performance additive to reduce friction and improve resistance to wear, chemicals, and water. Its extremely fine particles are blended into other materials—such as plastics, coatings, inks, and lubricants—to impart PTFE's desirable properties onto a host product.

The core value of Polytetrafluoroethylene (PTFE) is not just one feature, but a powerful combination of three: an exceptionally low coefficient of friction, near-total chemical inertness, and superior non-stick characteristics. This trio makes it an indispensable problem-solver across a vast range of industrial, commercial, and medical applications.

The Core Properties Driving PTFE's Use

To understand where PTFE is used, you must first understand its fundamental strengths. Its applications are a direct result of its unique molecular structure.

Unmatched Friction Reduction

PTFE has one of the lowest coefficients of friction of any known solid material, often compared to wet ice on wet ice. This makes it an ideal choice for components where smooth, low-wear movement is critical.

This property is leveraged in bearings, bushings, gears, and slide plates for machinery. It is also a key additive in performance lubricants and greases.

Extreme Chemical Inertness

PTFE is highly unreactive and can withstand a wide range of aggressive chemicals, solvents, and acids without degrading. This makes it invaluable for harsh industrial environments.

You will find it used for seals, gaskets, and washers in pumps and valves, as well as for linings in pipes and chemical tanks to protect the underlying structure from corrosion.

Superior Non-Stick & Water Repellency

The surface energy of PTFE is extremely low, meaning other substances do not stick to it readily. This property, combined with its hydrophobia (water repellency), is famous in consumer and industrial settings.

The most common examples are non-stick coatings for cookware and stain-resistant treatments for fabrics and carpets. It is also used for weatherproofing outdoor signs and creating protective, self-cleaning coatings for architectural roofs.

High-Performance Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength, meaning it can withstand high voltages without breaking down. It also maintains these properties over a wide range of frequencies and temperatures.

This makes it a preferred material for insulating high-performance cables and wires, especially in demanding aerospace and computing applications.

Biocompatibility and Purity

Because PTFE is so inert, it does not react with bodily tissues, making it safe for medical use. Its purity is also critical for sensitive applications.

This leads to its use in manufacturing medical devices like vascular grafts and various components used in the food and beverage industry where contamination is not an option.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Mechanical Strength

PTFE is a relatively soft material. It can be prone to "creep" (deforming under sustained pressure) and has lower tensile strength compared to engineering plastics like nylon or PEEK. For this reason, it is often reinforced with fillers like glass fiber or carbon to improve its mechanical properties.

Thermal Degradation

PTFE has an excellent operational temperature range, but it has a distinct upper limit. When heated above approximately 350°C (662°F), it can begin to decompose and release potentially harmful fumes. This is a critical design consideration for any high-temperature application.

Cost and Processing

Compared to common commodity plastics, PTFE is more expensive. It also cannot be processed using conventional melt-processing techniques like injection molding, requiring specialized methods like sintering, which can add to manufacturing complexity.

Making the Right Choice for Your Goal

Your specific goal will determine how you leverage PTFE's unique characteristics.

- If your primary focus is reducing mechanical wear and friction: Your best applications are as an additive in lubricants or incorporated into self-lubricating plastics for bearings, gears, and seals.

- If your primary focus is handling corrosive chemicals: Use PTFE for gaskets, pump components, and as a protective lining for pipes and vessels.

- If your primary focus is creating a non-stick or repellent surface: The ideal use is in coatings for cookware, industrial molds, or as a treatment for performance textiles.

- If your primary focus is electrical insulation: Specify PTFE for critical wiring and cable jacketing where signal integrity and reliability are paramount.

Ultimately, PTFE's value lies in its ability to perform reliably where many other materials would quickly fail.

Summary Table:

| Key Property | Primary Application Examples |

|---|---|

| Low Friction | Lubricants, self-lubricating plastics, bearings, gears |

| Chemical Inertness | Seals, gaskets, chemical tank linings, pump components |

| Non-Stick & Water Repellent | Non-stick coatings, fabric treatments, architectural coatings |

| Electrical Insulation | High-performance cables, wiring, aerospace components |

| Biocompatibility | Medical devices, food & beverage industry components |

Need high-performance PTFE components tailored to your application?

KINTEK specializes in the precision manufacturing of custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, we deliver solutions that leverage PTFE's unique properties to solve your toughest challenges in friction reduction, chemical resistance, and insulation.

Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments