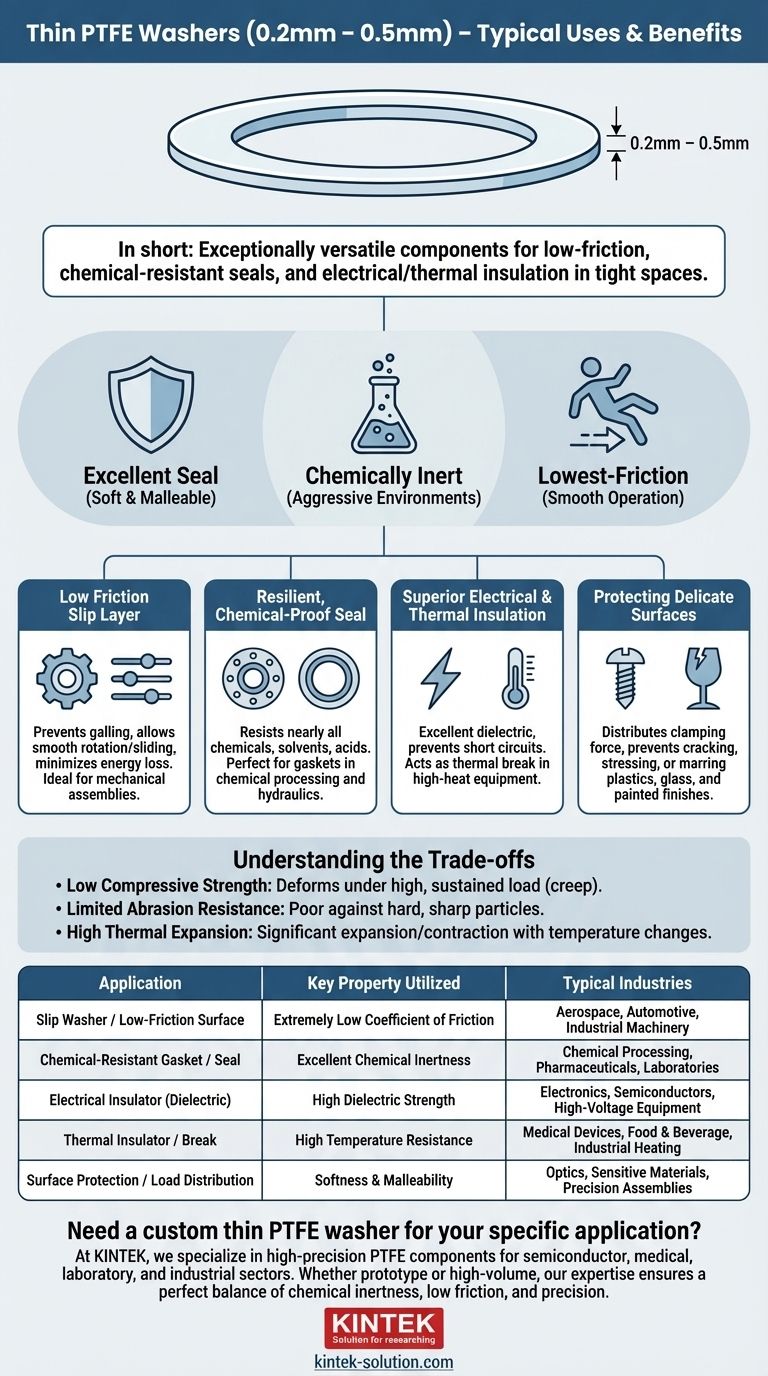

In short, thin PTFE washers (0.2mm – 0.5mm) are exceptionally versatile components used for creating low-friction slip surfaces, providing chemical-resistant seals, and delivering electrical or thermal insulation in applications where space is at a premium. Their unique properties make them indispensable in industries ranging from aerospace and electronics to chemical processing and medical devices.

The core value of a thin PTFE washer lies in its unique combination of properties: it is soft enough to create an excellent seal, chemically inert enough to handle aggressive environments, and one of the lowest-friction materials known, making it a multifunctional problem-solver for demanding engineering challenges.

Key Applications Driven by Core Properties

The utility of a thin PTFE washer is not about a single feature, but the interplay of several key material characteristics. Understanding these properties reveals why it is chosen for such a wide array of tasks.

The Critical Role of Low Friction

PTFE, widely known by the brand name Teflon®, has one of the lowest coefficients of friction of any solid material. This "slipperiness" is its most famous trait.

In a thin washer, this property is used to create a wear-resistant slip layer between two moving parts. It prevents galling and seizing in mechanical assemblies, allowing components to rotate or slide smoothly with minimal energy loss.

Creating a Resilient, Chemical-Proof Seal

PTFE is almost completely chemically inert, meaning it resists reaction with nearly all industrial chemicals, solvents, and acids.

This makes thin PTFE washers ideal for use as gaskets and seals in demanding environments like chemical processing plants, laboratories, and hydraulic or pneumatic systems. Its relative softness allows it to deform under pressure, creating a tight, reliable seal against leakage.

Superior Electrical and Thermal Insulation

PTFE is an excellent electrical insulator, or dielectric. It does not conduct electricity, making it perfect for applications where electrical isolation is critical.

A thin washer can be placed under a screw or around a connector in electronic assemblies to prevent short circuits. It also has a high-temperature resistance, allowing it to act as a thermal break or insulator in equipment that generates significant heat.

Protecting Delicate Surfaces

The softness and malleability of PTFE serve another crucial purpose: load distribution.

When fastening a screw or bolt onto a delicate surface like plastic, glass, or a painted finish, a thin PTFE washer under the head distributes the clamping force over a wider area. This prevents the fastener from cracking, stressing, or marring the material underneath.

Understanding the Trade-offs

While incredibly useful, PTFE is not the solution for every problem. Its unique properties come with limitations that are critical to understand for proper application.

Low Compressive Strength

PTFE is a soft material. Under a high, sustained load, it can suffer from "creep," meaning it will slowly deform permanently. This must be accounted for in high-pressure sealing or structural applications.

Limited Abrasion Resistance

While PTFE excels in low-friction sliding wear, it performs poorly against abrasive wear. Hard, sharp particles can easily gouge and remove the material. It is best suited for clean environments with smooth mating surfaces.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than most metals. In designs with very tight tolerances that experience wide temperature swings, this characteristic must be factored in to avoid component binding or failure.

Making the Right Choice for Your Goal

Selecting a thin PTFE washer is about matching its strengths to your specific engineering challenge.

- If your primary focus is reducing friction between moving parts: Use it as a slip washer in low-load mechanical assemblies to ensure smooth, quiet operation.

- If your primary focus is sealing aggressive chemicals or fluids: It is an ideal gasket material for fittings and flanges in chemical, pharmaceutical, or food processing lines.

- If your primary focus is electrical isolation: It is the perfect choice for insulating fasteners and components in electronics and high-voltage equipment.

- If your primary focus is protecting a sensitive surface: Place it under the head of any fastener to distribute clamping force without causing damage.

Ultimately, the thin PTFE washer is a uniquely effective component for solving complex sealing, wear, and insulation problems in confined spaces.

Summary Table:

| Application | Key Property Utilized | Typical Industries |

|---|---|---|

| Slip Washer / Low-Friction Surface | Extremely Low Coefficient of Friction | Aerospace, Automotive, Industrial Machinery |

| Chemical-Resistant Gasket / Seal | Excellent Chemical Inertness | Chemical Processing, Pharmaceuticals, Laboratories |

| Electrical Insulator (Dielectric) | High Dielectric Strength | Electronics, Semiconductors, High-Voltage Equipment |

| Thermal Insulator / Break | High Temperature Resistance | Medical Devices, Food & Beverage, Industrial Heating |

| Surface Protection / Load Distribution | Softness & Malleability | Optics, Sensitive Materials, Precision Assemblies |

Need a custom thin PTFE washer for your specific application?

At KINTEK, we specialize in manufacturing high-precision PTFE components like seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our expertise ensures you get a component that perfectly balances the unique properties of PTFE—like chemical inertness and low friction—with the precision required for your demanding environment.

Contact our engineering team today to discuss your requirements and get a solution that fits your exact needs.

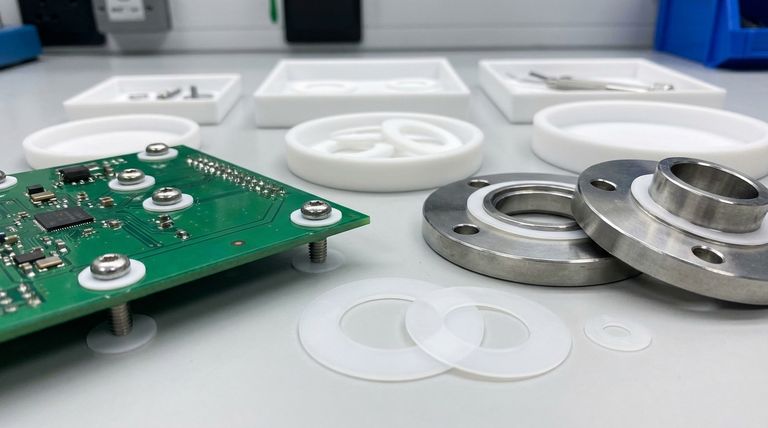

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications