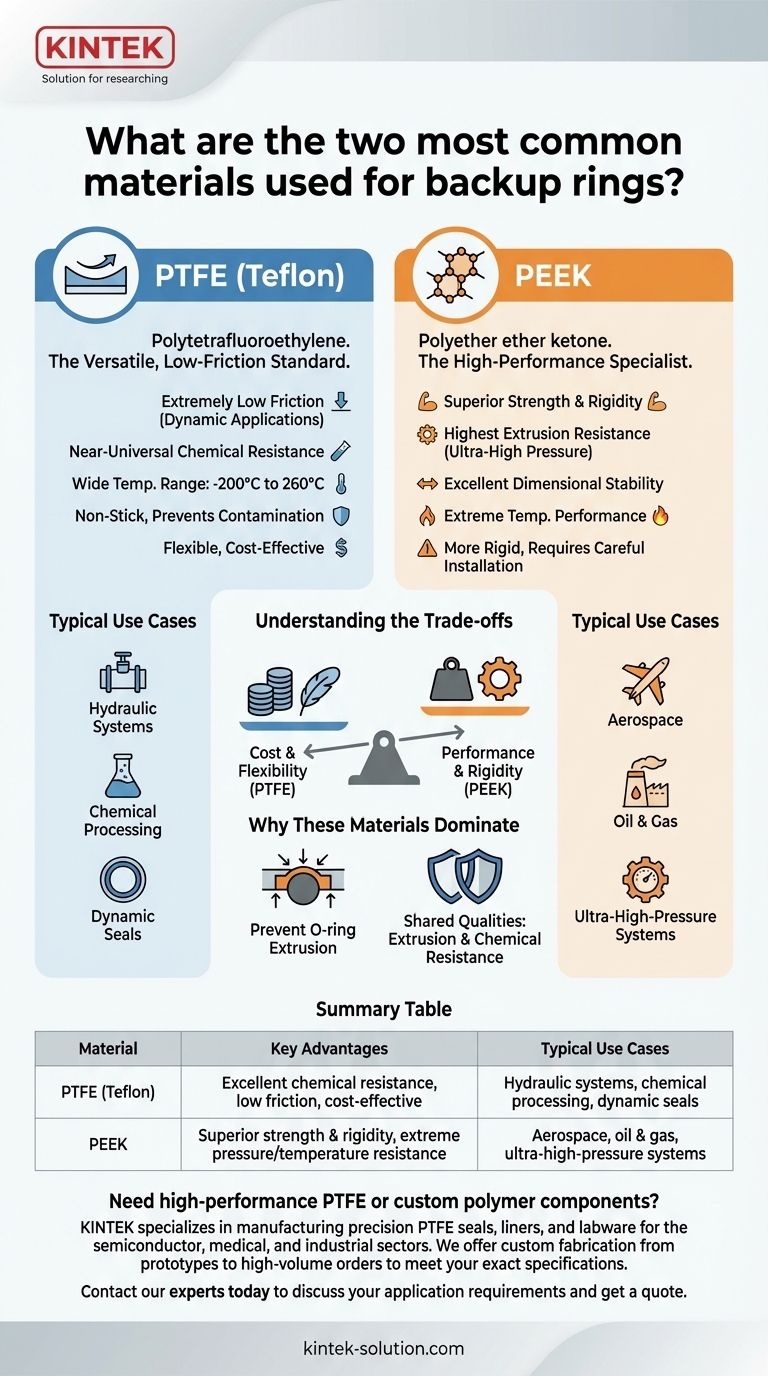

The two most common materials used for backup rings are PTFE (polytetrafluoroethylene), often known by its brand name Teflon, and PEEK (polyether ether ketone). Both are high-performance polymers chosen for their exceptional resistance to extrusion, chemicals, and high temperatures in demanding sealing applications.

The core decision between PTFE and PEEK comes down to a trade-off. PTFE is the versatile, low-friction standard for a wide range of applications, while PEEK offers superior mechanical strength for the most extreme pressure and temperature conditions.

Why These Materials Dominate

The Core Function of a Backup Ring

A backup ring is a rigid ring that provides support for a softer elastomeric seal, like an O-ring. Its primary job is to prevent the O-ring from extruding into the clearance gap between hardware components when subjected to high pressure.

Shared Qualities: Extrusion and Chemical Resistance

Both PTFE and PEEK are standard choices because they possess the necessary hardness and material properties to resist deformation under pressure.

They are also highly resistant to a broad spectrum of chemicals and can operate reliably across a wide temperature range, ensuring the integrity of the sealing system in harsh environments.

A Deeper Look at Each Material

PTFE: The Low-Friction Standard

PTFE is renowned for its extremely low coefficient of friction, making it the ideal choice for dynamic applications where minimizing drag is critical.

It offers near-universal chemical resistance, remaining stable in almost all industrial chemicals and solvents. PTFE also functions effectively in a vast temperature range, from -200°C to 260°C (-328°F to 500°F).

Its non-stick surface properties also help prevent system contamination, which is crucial in industries like food and beverage or pharmaceuticals.

PEEK: The High-Performance Specialist

PEEK is selected when operational demands exceed the mechanical limits of PTFE. It provides superior strength, stiffness, and dimensional stability, especially at elevated temperatures.

This material offers the highest level of extrusion resistance, making it essential for ultra-high-pressure hydraulic and pneumatic systems where clearance gaps can be larger or pressure spikes are common.

Understanding the Trade-offs

Cost vs. Performance

Generally, PEEK is a more expensive material than PTFE. Its use is typically justified only when the extreme pressure, temperature, or wear resistance requirements of an application make PTFE unsuitable.

Flexibility vs. Rigidity

PTFE is a relatively flexible material, which can ease installation. PEEK is significantly more rigid, providing maximum support but potentially requiring more careful installation procedures to avoid damage.

Common Applications and Forms

Where These Rings Are Used

Backup rings made from these materials are essential components in hydraulic cylinders, pneumatic systems, high-pressure valves, and chemical processing equipment. They are staples in the aerospace, automotive, and oil and gas industries.

Common Configurations

Backup rings are manufactured in several standard shapes to suit different groove dimensions and applications. Common forms include solid, spiral-cut, and single-turn (or "scarf-cut") rings.

Making the Right Choice for Your Application

Choosing the correct material is fundamental to ensuring the long-term reliability and safety of a sealing system.

- If your primary focus is broad chemical compatibility and low friction in dynamic systems: PTFE is the most versatile and cost-effective choice for the majority of industrial applications.

- If your primary focus is maximum extrusion resistance in extreme-pressure or high-temperature environments: PEEK provides the necessary mechanical strength and rigidity that PTFE cannot.

Ultimately, selecting the right backup ring material prevents seal failure and extends the operational life of your equipment.

Summary Table:

| Material | Key Advantages | Typical Use Cases |

|---|---|---|

| PTFE (Teflon) | Excellent chemical resistance, low friction, cost-effective | Hydraulic systems, chemical processing, dynamic seals |

| PEEK | Superior strength & rigidity, extreme pressure/temperature resistance | Aerospace, oil & gas, ultra-high-pressure systems |

Need high-performance PTFE or custom polymer components?

KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss your application requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications