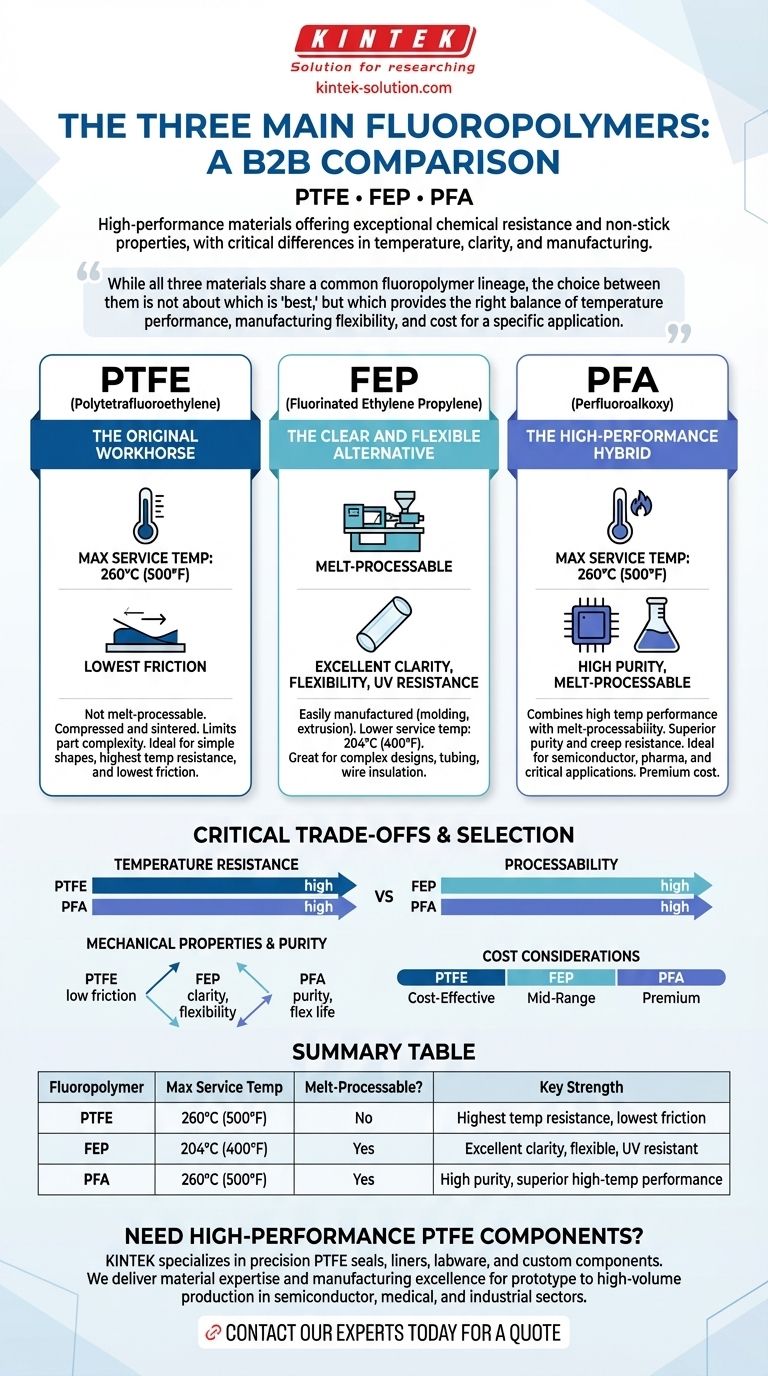

At the core of high-performance material science, the three main fluoropolymers available for industrial applications are PTFE (polytetrafluoroethylene), FEP (fluorinated ethylene propylene), and PFA (perfluoroalkoxy). Each of these materials offers exceptional chemical resistance and non-stick properties, but they possess critical differences in temperature resistance, optical clarity, and how they can be manufactured into final parts.

While all three materials share a common fluoropolymer lineage, the choice between them is not about which is "best," but which provides the right balance of temperature performance, manufacturing flexibility, and cost for a specific application.

A Closer Look at the "Big Three" Fluoropolymers

Understanding the fundamental characteristics of each material is the first step in making an informed selection. They are not interchangeable, and the success of a component often depends on choosing the correct one.

PTFE (Polytetrafluoroethylene): The Original Workhorse

PTFE is the most widely known fluoropolymer, often recognized by the brand name Teflon®. It set the original standard for chemical inertness and performance at extreme temperatures.

Its most defining characteristic is its incredibly high service temperature, typically up to 260°C (500°F). It also has the lowest coefficient of friction of any solid material, making it exceptionally slippery.

However, PTFE is not melt-processable. It cannot be molded or extruded like a conventional thermoplastic. Instead, it must be compressed and sintered—a process that limits the complexity of parts that can be made.

FEP (Fluorinated Ethylene Propylene): The Clear and Flexible Alternative

FEP was developed as a true melt-processable alternative to PTFE. This means it can be easily manufactured into complex designs using conventional injection molding and extrusion.

This processability allows for long, continuous lengths of tubing, intricate wire insulation, and clear, non-porous films. FEP is also highly transparent and has excellent UV resistance.

The primary trade-off is a lower service temperature, which is around 204°C (400°F). This makes it unsuitable for the most extreme heat applications where PTFE or PFA would be required.

PFA (Perfluoroalkoxy): The High-Performance Hybrid

PFA effectively combines the best attributes of both PTFE and FEP. It offers a service temperature that is nearly as high as PTFE—up to 260°C (500°F)—while also being fully melt-processable.

This unique combination makes it ideal for highly demanding applications. PFA provides superior purity, better creep resistance at high temperatures, and a smoother surface finish than FEP.

These premium properties make PFA the material of choice for the semiconductor, pharmaceutical, and aggressive chemical processing industries, where performance and purity are non-negotiable.

Understanding the Critical Trade-offs

Selecting the right fluoropolymer requires a clear understanding of the compromises you are making between performance, processability, and price.

Temperature Resistance vs. Processability

This is the central trade-off. PTFE offers the highest heat resistance but cannot be melted into complex shapes. FEP offers excellent melt-processability but has the lowest heat resistance of the three.

PFA bridges this gap by providing both high-temperature performance and melt-processability, but this capability comes at a significant cost premium.

Mechanical Properties and Purity

Each material excels in different areas. PTFE is unmatched for its low friction (lubricity). FEP offers superior optical clarity and flexibility.

PFA generally has the best flex life and the highest level of purity, which is critical for preventing contamination in sensitive processes like semiconductor manufacturing.

Cost Considerations

Cost is often a deciding factor. Generally, PTFE can be the most cost-effective option for simple shapes like sheets or basic machined parts. FEP is a mid-range option, valued for its processing versatility.

PFA is almost always the most expensive of the three due to its more complex chemistry and premium performance profile.

Making the Right Choice for Your Application

Your final decision should be driven entirely by the specific demands of your project.

- If your primary focus is maximum temperature and chemical resistance for a simple shape: PTFE is the established and often most cost-effective standard.

- If your primary focus is optical clarity, flexibility, and manufacturing complex parts via extrusion or molding: FEP is the ideal choice, provided the application's temperature is below 204°C.

- If your primary focus is combining high-temperature performance with melt-processability for high-purity or critical applications: PFA is the definitive, premium solution.

By aligning the unique strengths of each material with your specific goals, you can ensure optimal performance and reliability in your design.

Summary Table:

| Fluoropolymer | Max Service Temp | Melt-Processable? | Key Strength |

|---|---|---|---|

| PTFE | 260°C (500°F) | No | Highest temp resistance, lowest friction |

| FEP | 204°C (400°F) | Yes | Excellent clarity, flexible, UV resistant |

| PFA | 260°C (500°F) | Yes | High purity, superior high-temp performance |

Need High-Performance PTFE Components?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, labware, and custom components. Whether your project in the semiconductor, medical, laboratory, or industrial sector requires prototypes or high-volume production, we deliver the material expertise and manufacturing excellence to ensure your application's success.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How can PTFE's wear resistance be improved? Boost Durability with Filled PTFE Compounds

- What benefits does Teflon coating offer in chemical manufacturing? Boost Equipment Lifespan & Purity

- What are some common uses of Teflon? Discover Its Critical Role in Engineering

- What chemicals is PTFE resistant to? Discover Its Near-Universal Chemical Inertness

- How does graphite-filled PTFE perform? A Guide to Superior Self-Lubricating Components

- What are the key features of PTFE laminated fabric? Unmatched Protection & Breathability

- How is Teflon coating used in the food and kitchenware industry? Enhancing Efficiency and Product Quality

- What is Teflon/PTFE and what are its key properties? Discover the Premier High-Performance Polymer