Polytetrafluoroethylene (PTFE) possesses exceptional thermal and chemical stability, making it one of the most resilient and reliable polymers for demanding applications. Its performance stems from the powerful carbon-fluorine bonds that form its molecular backbone. This structure allows it to operate continuously in a wide temperature range from -200°C to 260°C and resist chemical attack from nearly all corrosive agents.

The core of PTFE's value lies in its fundamental inertness. Its unique molecular structure creates a material that is not only resistant to extreme heat and cold but is also virtually unaffected by chemicals that would dissolve or degrade almost any other plastic.

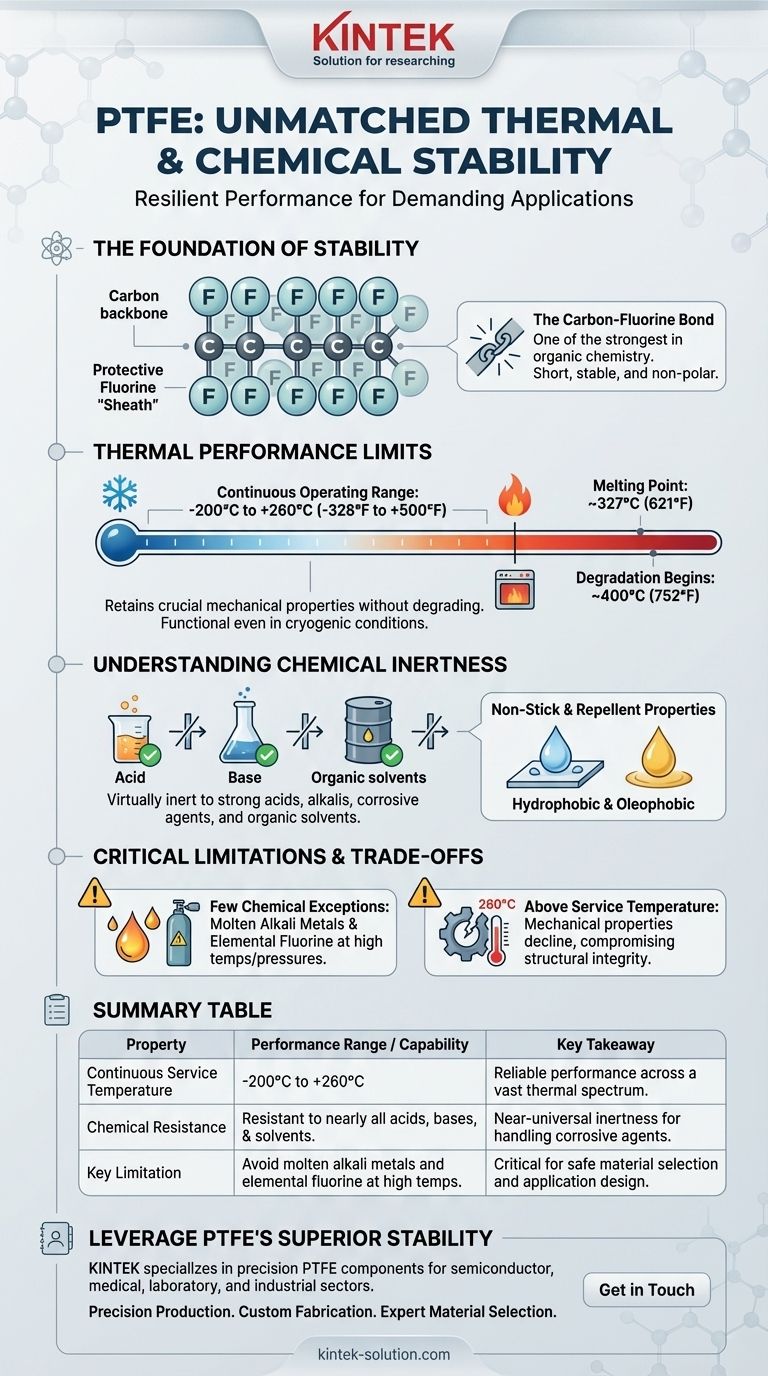

The Foundation of Stability: The Carbon-Fluorine Bond

At the heart of PTFE's remarkable properties is the bond between its carbon and fluorine atoms. This molecular architecture is the source of its thermal and chemical resilience.

Why This Bond is So Strong

The carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry. Fluorine's high electronegativity creates a very short, stable, and non-polar bond with carbon, which is incredibly difficult to break.

The Protective Fluorine "Sheath"

In the PTFE polymer chain, the larger fluorine atoms form a tight, uniform helix around the central carbon backbone. This compact interlocking structure effectively shields the carbon atoms from any potential chemical attack.

Defining the Thermal Performance Limits

PTFE maintains its integrity and function across a vast temperature spectrum, outperforming most other plastics in both high-heat and cryogenic conditions.

The Continuous Operating Range

The key specification for PTFE is its continuous service temperature, which ranges from -200°C to +260°C (-328°F to +500°F). Within this window, the material retains its crucial mechanical properties without degrading.

Melting and Degradation Points

While its functional limit is 260°C, PTFE's actual melting point is significantly higher, around 327°C (621°F). Significant thermal degradation, where the molecular structure begins to break down, does not occur until temperatures approach 400°C (752°F).

Stability in Extreme Cold

Unlike many polymers that become brittle and fail at low temperatures, PTFE remains flexible and functional even in cryogenic conditions down to -200°C.

Understanding the Chemical Inertness

PTFE's chemical resistance is nearly universal, making it the default choice for applications involving highly corrosive substances.

Resistance to Corrosive Agents

It is virtually inert to a vast range of chemicals, including strong acids, alkalis, corrosive agents, and organic solvents. This makes it invaluable for seals, gaskets, and linings in chemical processing equipment.

Non-Stick and Repellent Properties

The same chemical stability that protects the polymer also results in very low surface energy. This is why PTFE is both hydrophobic (water-repellent) and oleophobic (oil-repellent), giving it its famous non-stick characteristic.

Critical Limitations and Trade-offs

While exceptionally robust, PTFE is not invincible. Understanding its specific vulnerabilities is crucial for proper material selection and safe operation.

The Few Chemical Exceptions

PTFE's near-total chemical resistance has a few rare exceptions. It can be attacked by highly reactive substances such as molten alkali metals (like liquid sodium) and elemental fluorine gas at elevated temperatures and pressures.

Behavior Above the Service Temperature

Operating PTFE above its 260°C continuous limit is a critical consideration. While it will not melt immediately, its mechanical properties—such as compressive strength and wear resistance—will begin to decline, compromising its structural integrity.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE's stability profile matches your needs.

- If your primary focus is high-temperature stability: PTFE is a premier choice for continuous use up to 260°C, providing reliable performance where most other plastics would fail.

- If your primary focus is chemical resistance: PTFE offers near-universal inertness, making it the ideal material for handling aggressive acids, bases, and solvents.

- If you are engineering for extreme environments: Respect PTFE's 260°C service limit for mechanical integrity and be aware of its few chemical vulnerabilities, particularly molten alkali metals and high-temperature fluorine.

By understanding both its remarkable strengths and its specific limitations, you can confidently leverage PTFE in the most demanding environments.

Summary Table:

| Property | Performance Range / Capability | Key Takeaway |

|---|---|---|

| Continuous Service Temperature | -200°C to +260°C (-328°F to +500°F) | Reliable performance across a vast thermal spectrum. |

| Chemical Resistance | Resistant to nearly all acids, bases, and solvents. | Near-universal inertness for handling corrosive agents. |

| Key Limitation | Avoid molten alkali metals and elemental fluorine at high temps. | Critical for safe material selection and application design. |

Leverage PTFE's Superior Stability for Your Critical Components

Do you need high-performance PTFE seals, liners, or custom labware that can withstand extreme temperatures and aggressive chemicals? KINTEK specializes in manufacturing precision PTFE components for the semiconductor, medical, laboratory, and specialized industrial sectors.

We deliver the material reliability your applications demand:

- Precision Production: Ensuring consistent quality and performance in every part.

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Expert Material Selection: Guiding you to the right solution for your specific thermal and chemical environment.

Contact us today to discuss your project requirements and get a quote. Get in Touch

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications