From a technical standpoint, the primary advantage of Polytetrafluoroethylene (PTFE) slide bearings is their extremely low coefficient of friction, the lowest of any solid engineering material. This core property enables a cascade of benefits, including maintenance-free operation, exceptional durability due to chemical inertness, and the complete elimination of "stick-slip" motion.

PTFE slide bearings are not just components; they are engineering solutions that decouple structures to manage immense forces and movements. Their true value lies in providing this controlled motion with unparalleled simplicity and reliability, eliminating the long-term operational costs and failure points common in complex mechanical alternatives.

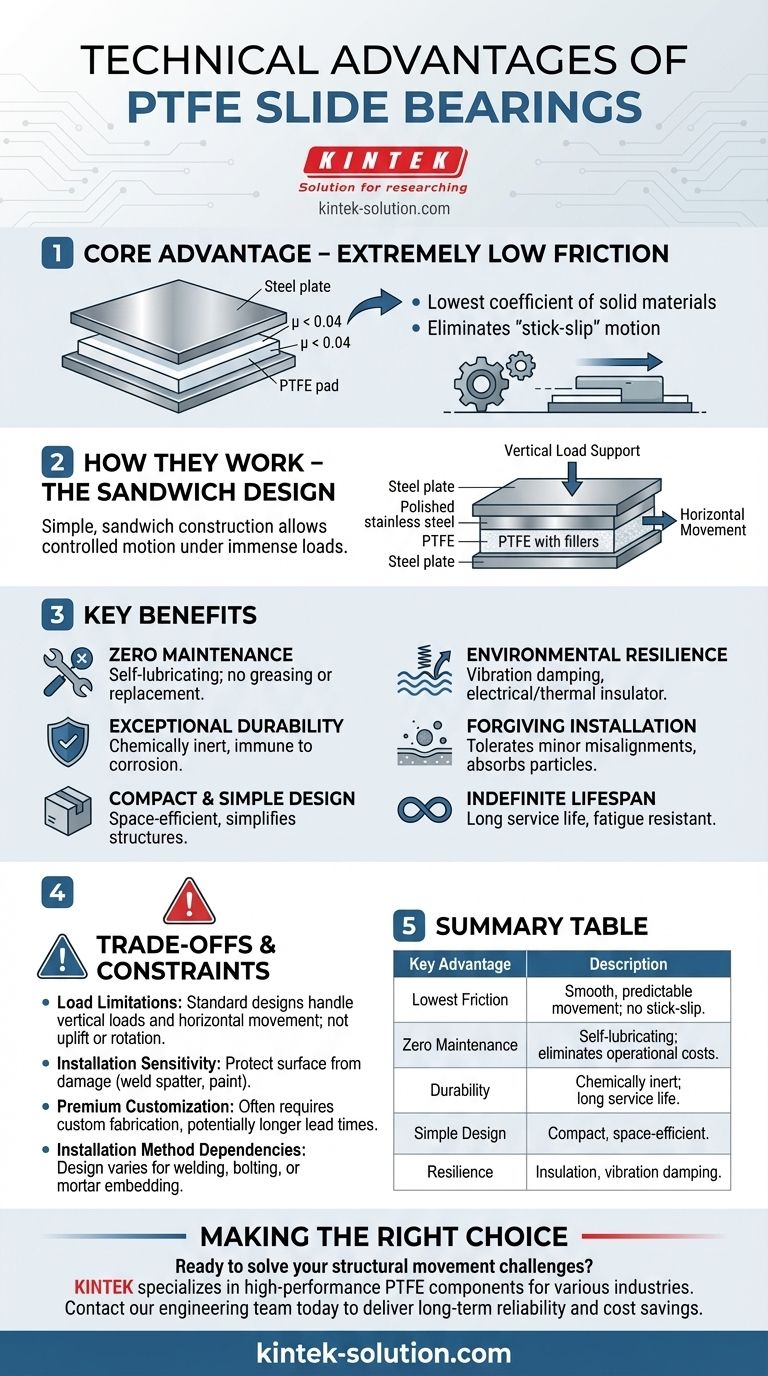

The Fundamental Principles of PTFE Bearings

PTFE slide bearings are designed to solve a simple but critical engineering problem: allowing a structure to move in a controlled manner while continuously supporting its weight.

How They Work

The typical design consists of two steel plates. One plate is faced with a layer of PTFE (often containing fillers to improve properties), which slides against a highly polished stainless steel surface on the opposing plate.

This simple "sandwich" construction supports immense vertical loads while permitting translation in longitudinal and transverse directions unless specifically restrained.

The Core Advantage: Near-Frictionless Movement

PTFE's exceptionally low coefficient of friction is the central benefit from which all others derive. It ensures smooth, predictable movement under load.

Crucially, this eliminates the stick-slip phenomenon, where static friction builds up and releases suddenly, causing jarring motion. PTFE bearings move smoothly from a complete standstill.

Intrinsic Durability and Lifespan

PTFE is one of the most chemically inert substances known, making it immune to corrosion and degradation from environmental factors.

This chemical stability, combined with its resistance to fatigue failure, gives the bearing a theoretically indefinite service life when properly designed and installed.

Key Operational and Design Benefits

The material properties of PTFE translate directly into significant advantages for designers, engineers, and asset owners.

Zero Maintenance, Indefinite Lifespan

Because PTFE is self-lubricating, the bearings require absolutely no maintenance, greasing, or part replacement over their entire life. This dramatically reduces long-term operational costs.

Compact and Simple Design

Compared to mechanical alternatives like roller or pot bearings, PTFE slide bearings have a much simpler, more compact profile. This simplifies the surrounding structural design and reduces material requirements.

Environmental Resilience

PTFE bearings are excellent electrical and thermal insulators, preventing unwanted energy transfer between structural elements. They also provide effective vibration damping.

Furthermore, the bearing surface has a unique ability to absorb small dirt particles, preventing scoring and maintaining its low-friction performance in real-world conditions.

Forgiving Installation

The nature of a sliding surface allows the bearing to tolerate minor misalignments between structural elements without compromising its function or longevity.

Understanding the Trade-offs and Practical Constraints

While highly effective, PTFE bearings are not a universal solution. Understanding their limitations is critical for successful implementation.

Load and Direction Limitations

Standard PTFE slide bearings are designed to support vertical loads and allow horizontal movement. They are not intended to handle uplift forces or significant rotational movements without specialized design modifications.

Sensitivity During Installation

The PTFE and stainless steel surfaces are the heart of the bearing. They must be rigorously protected from weld spatter, paint, and metal swarf during construction, as surface damage can compromise performance.

The "Premium Customization" Factor

While the design is simple, PTFE bearings are often specified late in the design process to solve complex interface issues. This can lead to them being treated as premium, custom-fabricated products with short lead times, impacting project costs.

Installation Method Dependencies

The bearing must be chosen based on the installation method. Different designs are required for full welding, tack-welding, bolting, or embedding in mortar, and this decision must be made early.

Making the Right Choice for Your Project

Choosing a bearing system depends entirely on your project's non-negotiable requirements and long-term goals.

- If your primary focus is long-term reliability and zero maintenance: PTFE is the ideal choice due to its chemical inertness and self-lubricating properties, which eliminate operational costs.

- If your primary focus is accommodating predictable thermal or seismic movement: The simple, low-friction design of PTFE bearings provides the most dependable and straightforward solution for decoupling structures.

- If your primary focus is managing complex, multi-directional loads: A standard PTFE bearing may be insufficient, and you should investigate more complex solutions like pot or spherical bearings, which may incorporate PTFE sliding surfaces.

Ultimately, PTFE slide bearings offer a powerful combination of performance and simplicity, solving complex structural challenges with an elegant, maintenance-free solution.

Summary Table:

| Key Advantage | Description |

|---|---|

| Lowest Coefficient of Friction | Enables smooth, predictable movement and eliminates stick-slip. |

| Zero Maintenance | Self-lubricating design eliminates greasing and part replacement. |

| Exceptional Durability | Chemically inert PTFE resists corrosion and offers a long service life. |

| Simple & Compact Design | More straightforward and space-efficient than mechanical alternatives. |

| Environmental Resilience | Provides excellent electrical/thermal insulation and vibration damping. |

Ready to solve your structural movement challenges with a reliable, maintenance-free solution?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom slide bearings for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures a bearing solution that delivers long-term reliability and cost savings.

Contact our engineering team today to discuss your project requirements and discover the KINTEK difference.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech