At their core, Teflon PFA encapsulated o-rings are composite seals designed for extreme environments. They consist of an elastic core, made from materials like silicone or FKM, which is completely enclosed in a seamless jacket of high-performance PFA (Perfluoroalkoxy) resin. This construction leverages the PFA's superior chemical inertness and temperature resistance while using the inner core to provide the flexibility and compression needed for a reliable seal.

The fundamental advantage of a PFA encapsulated o-ring is its ability to deliver the near-universal chemical inertness of solid Teflon while overcoming Teflon's inherent lack of elasticity. The elastomer core provides the necessary "spring back" for a reliable seal in applications where solid Teflon would fail due to compression set.

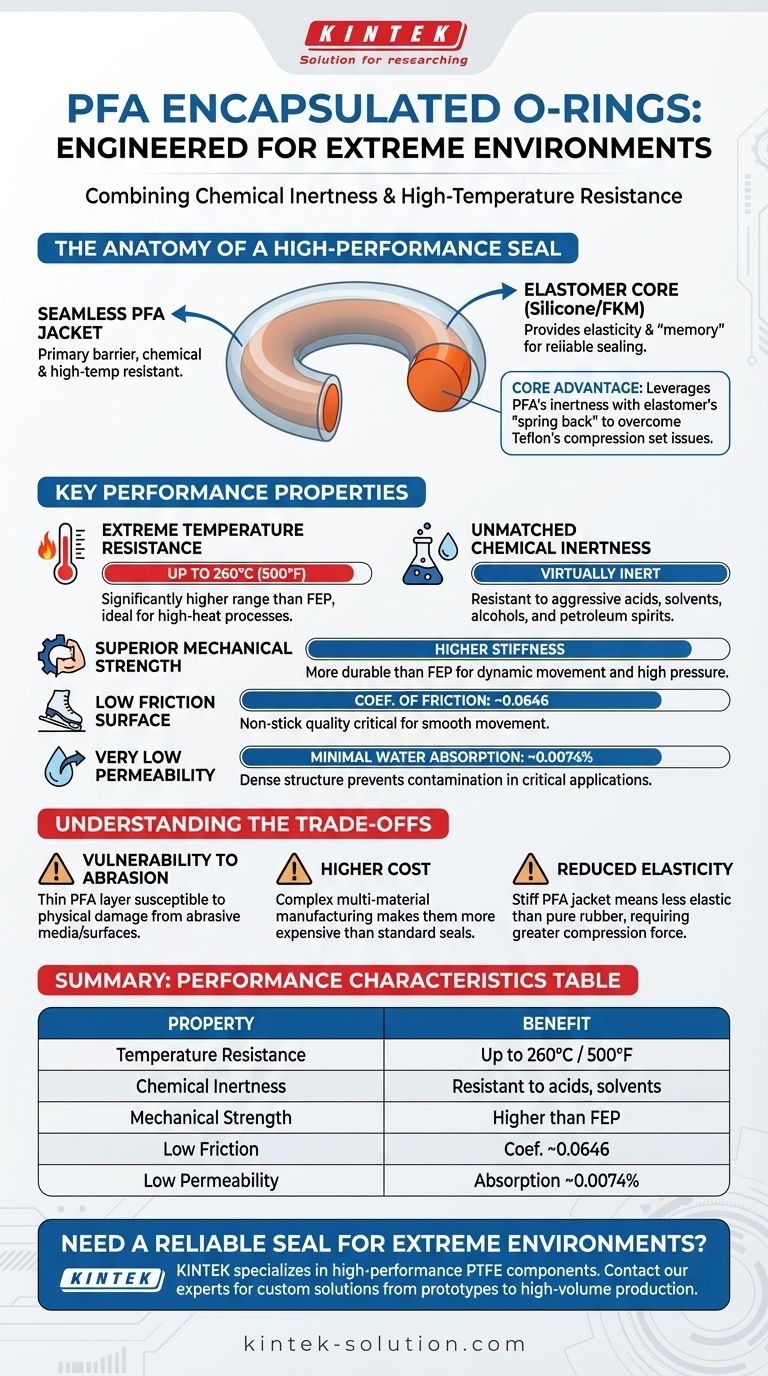

The Anatomy of a High-Performance Seal

To understand the properties of a PFA encapsulated o-ring, one must first understand its two-part construction. Each component serves a distinct and critical purpose.

The Seamless PFA Jacket

The outer jacket is the primary barrier against the operational environment. It is a seamless layer of Teflon PFA.

This jacket provides the o-ring's signature resistance to chemicals and extreme temperatures, effectively isolating the more vulnerable core.

The Elastomer Core

The inner core is typically made of Silicone or FKM (Viton®). This core does not contact the external media.

Its sole function is to provide the seal with elasticity and "memory," allowing it to compress and rebound to maintain a tight seal against a surface.

Key Performance Properties Explained

The combination of the PFA jacket and elastomer core results in a unique set of performance characteristics ideal for demanding industrial applications.

Extreme Temperature Resistance

PFA provides a significantly higher operational temperature range than its FEP counterpart.

These seals are capable of withstanding continuous service temperatures up to 260°C (500°F), making them suitable for high-heat processes.

Unmatched Chemical Inertness

The PFA jacket is virtually inert to almost all industrial chemicals.

This includes aggressive acids, aromatic solvents, alcohols, and petroleum spirits, protecting the core from degradation and extending the seal's lifespan.

Superior Mechanical Strength

When compared to other fluoropolymers like FEP, PFA stands out for its higher mechanical strength and stiffness.

This makes it more durable and resistant to physical wear in applications with dynamic movement or high pressure.

Low Friction Surface

Teflon PFA has an extremely low coefficient of friction (a typical value against steel is 0.0646).

This non-stick quality is critical in applications where smooth movement is required and prevents the o-ring from adhering to sealing surfaces.

Very Low Permeability

The dense, non-porous structure of the PFA jacket results in extremely low permeability and minimal water absorption (~0.0074%).

This property is vital in semiconductor manufacturing and pharmaceutical applications where preventing contamination is paramount.

Understanding the Inherent Trade-offs

While powerful, PFA encapsulated o-rings are not a universal solution. Their specialized construction comes with specific limitations that must be considered.

Vulnerability to Abrasion

The primary weakness of any encapsulated o-ring is the jacket's susceptibility to physical damage.

The thin PFA layer can be scratched or scored by abrasive media or rough sealing surfaces, which compromises the seal and exposes the inner core to chemical attack.

Higher Cost

The complex, multi-material manufacturing process makes these o-rings significantly more expensive than standard, single-material elastomer or even solid Teflon o-rings.

Reduced Elasticity vs. Pure Elastomers

While far more flexible than solid Teflon, the stiff PFA jacket makes the overall seal less elastic than a standard rubber o-ring.

This can require greater compression force to achieve a seal and may make installation more challenging in certain groove designs.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its properties to the demands of the environment.

- If your primary focus is extreme chemical compatibility and high temperatures: A PFA encapsulated o-ring is an ideal choice, offering protection that standard elastomers cannot match.

- If your application involves abrasive media or sharp surfaces: You must proceed with caution, as damaging the PFA jacket can lead to premature seal failure.

- If your budget is a primary constraint and the environment is less aggressive: A standard FKM or even a solid Teflon o-ring might be a more cost-effective solution.

Ultimately, understanding these properties empowers you to engineer a sealing solution that provides robust reliability where it matters most.

Summary Table:

| Property | Key Characteristic | Benefit |

|---|---|---|

| Temperature Resistance | Continuous service up to 260°C (500°F) | Ideal for high-heat processes |

| Chemical Inertness | Resistant to aggressive acids, solvents, and more | Protects against degradation in harsh environments |

| Mechanical Strength | Higher strength and stiffness than FEP | Durable for dynamic or high-pressure applications |

| Low Friction | Extremely low coefficient of friction (~0.0646) | Non-stick surface for smooth movement |

| Low Permeability | Minimal water absorption (~0.0074%) | Prevents contamination in critical applications like semiconductor manufacturing |

Need a reliable seal for extreme chemical or high-temperature environments?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom PFA encapsulated o-rings. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume production.

Let us help you engineer the perfect sealing solution for your demanding application. Contact our experts today to discuss your requirements and experience the KINTEK difference.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer