In short, adding carbon to PTFE transforms it from a soft, insulating material into a mechanically robust composite with excellent wear resistance and the ability to manage heat and static electricity. This enhancement comes without significantly sacrificing PTFE's signature low friction and chemical inertness.

The central purpose of creating carbon-filled PTFE is to overcome the physical limitations of pure PTFE. It's the material of choice when you need the slipperiness and chemical resistance of PTFE but in an application that demands higher strength, wear resistance, and thermal or electrical conductivity.

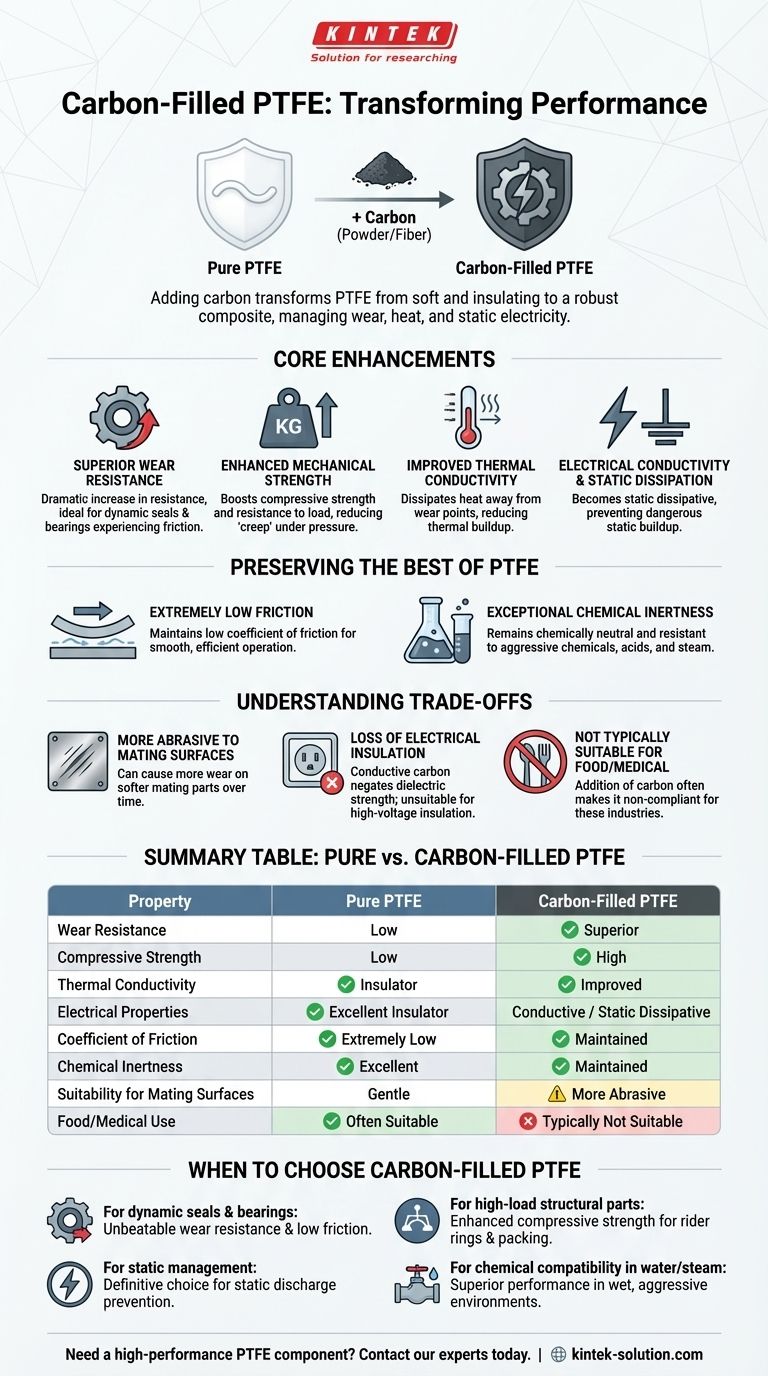

Why Add Carbon to PTFE? The Core Enhancements

Adding carbon, typically in powder or fiber form up to 35%, fundamentally improves the performance of PTFE in demanding mechanical and electrical applications.

Superior Wear and Abrasion Resistance

Carbon acts as a reinforcing agent within the PTFE matrix, dramatically increasing its resistance to wear. This makes it ideal for dynamic components like seals, bearings, and piston rings that experience constant friction.

Enhanced Mechanical Strength

Pure PTFE can deform or "creep" under sustained pressure. Carbon filler provides a significant boost in compressive strength and resistance to load, ensuring the material holds its shape in high-pressure environments.

Improved Thermal Conductivity

PTFE is an excellent thermal insulator, which can be a drawback if heat builds up at a wear point. Carbon enhances thermal conductivity, allowing the material to dissipate heat away from the surface, which further reduces wear and extends service life.

Electrical Conductivity and Static Dissipation

Perhaps one of its most critical properties, carbon filler makes PTFE electrically conductive. This turns it into a static dissipative material, perfect for applications where the buildup of static electricity is a concern or a safety hazard.

Preserving the Best of PTFE

While carbon adds new capabilities, the compound retains the most valuable inherent properties of virgin PTFE.

Extremely Low Coefficient of Friction

Carbon-filled PTFE maintains an exceptionally low coefficient of friction. It performs well in dry running conditions as well as in the presence of water and steam, ensuring smooth, efficient operation.

Exceptional Chemical Inertness

The material remains chemically neutral and highly resistant to corrosive chemicals, acids, and steam. This allows it to be used in aggressive industrial environments where other materials would quickly degrade.

Understanding the Trade-offs

No material is perfect. Choosing carbon-filled PTFE involves acknowledging a few key compromises compared to its unfilled counterpart.

Impact on Mating Surfaces

While carbon is less abrasive than other common fillers like glass, it is still harder than pure PTFE. Over time, it can cause more wear on softer mating surfaces (like stainless steel shafts) than unfilled PTFE would.

Loss of Electrical Insulation

Virgin PTFE is one of the best electrical insulators available. The addition of conductive carbon completely negates this property. If your application requires high dielectric strength, carbon-filled PTFE is the wrong choice.

Suitability for Food and Medical Use

While pure PTFE is often FDA-compliant, the addition of carbon fillers typically makes the compound unsuitable for applications in the food, beverage, or pharmaceutical industries.

When to Choose Carbon-Filled PTFE

Your specific goal will determine if this advanced composite is the right solution for your project.

- If your primary focus is dynamic seals and bearings: Choose carbon-filled PTFE for its unbeatable combination of low friction and high wear resistance, especially in non-lubricated systems.

- If your primary focus is managing static electricity: Its conductive properties make it the definitive choice for components in environments where static discharge must be prevented.

- If your primary focus is high-load structural parts: Rely on its enhanced compressive strength to create components like rider rings and packing that resist deformation under pressure.

- If your primary focus is chemical compatibility in water or steam: Its chemical inertness and excellent performance in wet environments make it a superior choice for pump and valve components.

Ultimately, carbon-filled PTFE is a strategic upgrade for applications where the limits of pure PTFE have been reached.

Summary Table:

| Property | Pure PTFE | Carbon-Filled PTFE |

|---|---|---|

| Wear Resistance | Low | Superior |

| Compressive Strength | Low | High |

| Thermal Conductivity | Insulator | Improved |

| Electrical Properties | Excellent Insulator | Conductive / Static Dissipative |

| Coefficient of Friction | Extremely Low | Maintained |

| Chemical Inertness | Excellent | Maintained |

| Suitability for Mating Surfaces | Gentle | More Abrasive |

| Food/Medical Use | Often Suitable | Typically Not Suitable |

Need a high-performance PTFE component for a demanding application?

At KINTEK, we specialize in precision manufacturing of carbon-filled PTFE components like seals, bearings, and liners. Our custom fabrication service, from prototypes to high-volume orders, ensures you get the exact material properties you need for success in the semiconductor, medical, laboratory, and industrial sectors.

Contact our experts today to discuss how our advanced PTFE solutions can solve your toughest engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments