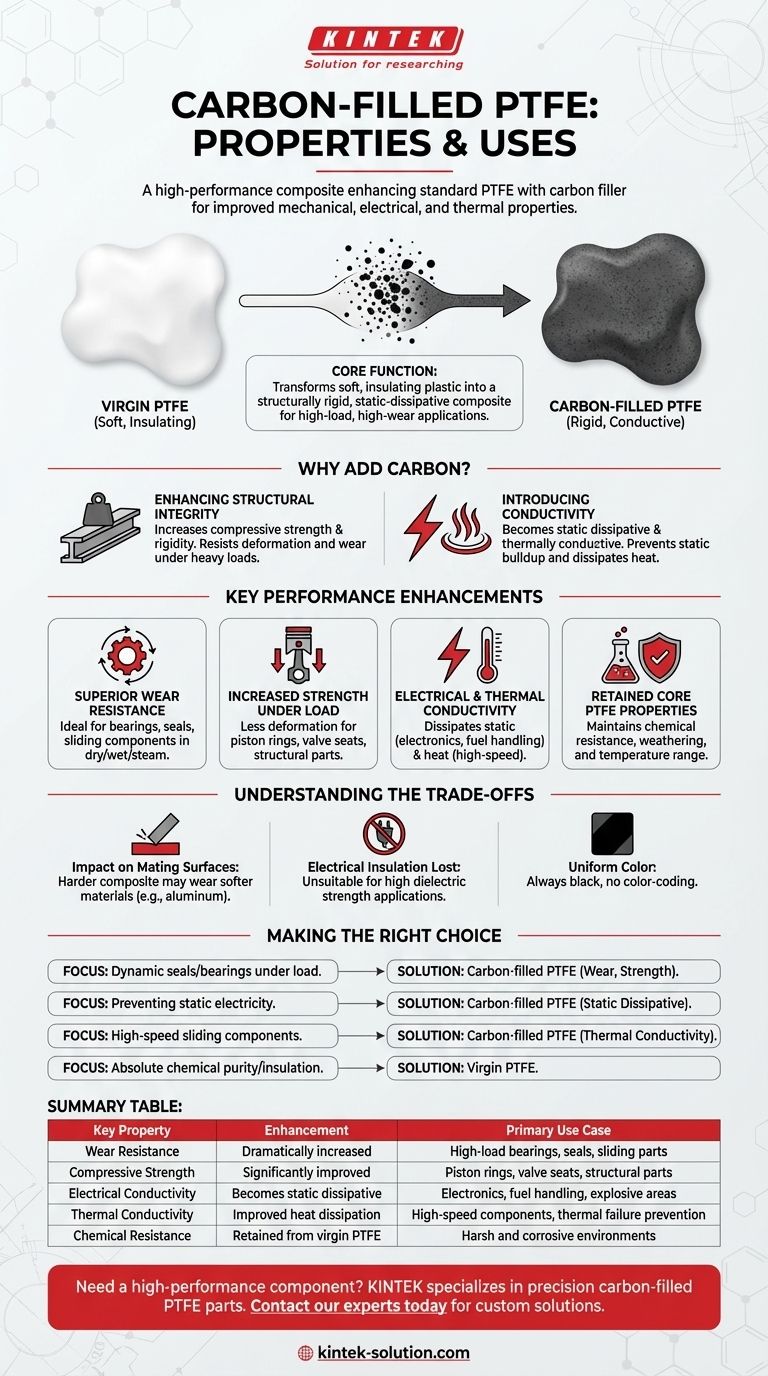

In essence, carbon-filled PTFE is a high-performance composite material that enhances standard Polytetrafluoroethylene (PTFE) by adding carbon as a reinforcing filler. This addition dramatically improves its mechanical properties, particularly wear resistance and compressive strength, while also making the material electrically and thermally conductive. It retains PTFE's signature low friction and chemical inertness, creating a robust material for demanding applications.

The core function of adding carbon to PTFE is to transform it from a soft, insulating plastic into a structurally rigid, conductive composite. This makes it ideal for high-load, high-wear mechanical applications where static electricity and heat dissipation are critical concerns.

Why Add Carbon to PTFE?

Pure, or "virgin," PTFE is known for its extreme chemical resistance and exceptionally low coefficient of friction. However, it is also a very soft material that suffers from high wear rates and "creep," a tendency to deform permanently under a sustained load. Adding carbon filler directly addresses these mechanical weaknesses.

Enhancing Structural Integrity

The carbon particles, which can be in powder or fiber form, act as a reinforcing agent within the PTFE matrix. This reinforcement significantly increases the material's compressive strength and rigidity.

As a result, carbon-filled PTFE resists deformation and wear far better than its unfilled counterpart, making it suitable for components that must endure heavy mechanical loads.

Introducing New Conductive Properties

Standard PTFE is an excellent electrical insulator. The addition of carbon, an electrically conductive element, transforms the material into a static dissipative composite.

This is a critical feature in applications where the buildup of static electricity from friction could damage sensitive electronics or create a spark hazard in flammable environments. Carbon also improves thermal conductivity, allowing the material to dissipate heat generated from friction more effectively.

Key Performance Enhancements

Combining PTFE with carbon creates a material with a unique and powerful set of properties, extending its use into far more aggressive environments.

Superior Wear Resistance

Carbon-filled PTFE offers exceptional wear and fatigue resistance. This makes it a preferred material for high-performance bearings, seals, and sliding components that experience constant friction. It performs well in dry, water, and even steam applications.

Increased Strength Under Load

Its enhanced compressive strength means it is far less likely to deform under heavy loads. This is crucial for components like piston rings, valve seats, and structural parts where dimensional stability is non-negotiable.

Electrical and Thermal Conductivity

The ability to dissipate static electricity is one of the most important advantages of carbon-filled PTFE. At the same time, its improved thermal conductivity prevents heat buildup in high-speed dynamic applications, reducing thermal expansion and the risk of component failure.

Retained Core PTFE Properties

Critically, carbon-filled PTFE retains the hallmark benefits of virgin PTFE. It remains highly resistant to chemicals, weathering, and a wide range of operating temperatures, ensuring reliability in harsh and corrosive settings.

Understanding the Trade-offs

While carbon-filled PTFE offers significant advantages, it is essential to understand its limitations to ensure it is the right choice for an application.

Impact on Mating Surfaces

The carbon filler makes the composite harder than pure PTFE. This can increase the wear on softer mating surfaces, such as aluminum or softer steels. The hardness of the corresponding component should always be a design consideration.

Electrical Insulation is Lost

Because the material becomes electrically conductive, it is entirely unsuitable for applications that require high dielectric strength or electrical insulation. In these cases, virgin PTFE or another filled grade would be necessary.

Uniform Color

Carbon-filled PTFE is always black. While this is rarely a functional issue, it eliminates any possibility of color-coding parts for identification.

Making the Right Choice for Your Application

Selecting the correct material grade is critical for performance and longevity. Your decision should be based on the primary challenge you are trying to solve.

- If your primary focus is dynamic seals or bearings under heavy load: Carbon-filled PTFE's combination of low friction, high wear resistance, and compressive strength is ideal.

- If your primary focus is preventing static electricity: Its static dissipative properties are essential for applications in electronics, fuel handling, or potentially explosive environments.

- If your primary focus is high-speed sliding components: The improved thermal conductivity will help dissipate frictional heat, maintaining dimensional stability and preventing premature failure.

- If your primary focus is absolute chemical purity or electrical insulation: Unfilled, virgin-grade PTFE is the correct choice, as the carbon filler compromises these specific properties.

By understanding these targeted enhancements, you can leverage carbon-filled PTFE to solve complex engineering challenges that pure PTFE cannot.

Summary Table:

| Key Property | Enhancement Over Virgin PTFE | Primary Use Case |

|---|---|---|

| Wear Resistance | Dramatically increased | High-load bearings, seals, and sliding parts |

| Compressive Strength | Significantly improved | Piston rings, valve seats, structural components |

| Electrical Conductivity | Becomes static dissipative | Electronics, fuel handling, explosive environments |

| Thermal Conductivity | Improved heat dissipation | High-speed components to prevent thermal failure |

| Chemical Resistance | Retained from virgin PTFE | Harsh and corrosive environments |

Need a high-performance component that can handle heavy loads, resist wear, and dissipate static?

KINTEK specializes in manufacturing precision carbon-filled PTFE components like seals, bearings, and liners for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication process, from prototypes to high-volume orders, ensures you get a part perfectly tailored to your application's demands.

Contact our experts today to discuss how our carbon-filled PTFE solutions can solve your toughest engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom Machined Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers