At their core, Teflon bushings serve three primary functions: to dramatically reduce friction between moving parts, to prevent the wear and surface damage that friction causes, and to provide exceptionally smooth, consistent movement within a mechanical system. Their unique material properties allow them to achieve this without the need for traditional liquid lubricants like grease or oil.

The true value of a Teflon bushing isn't just in separating two surfaces; it's in creating a self-lubricating, chemically inert, and high-temperature barrier that simplifies mechanical design, reduces maintenance, and extends the operational life of equipment.

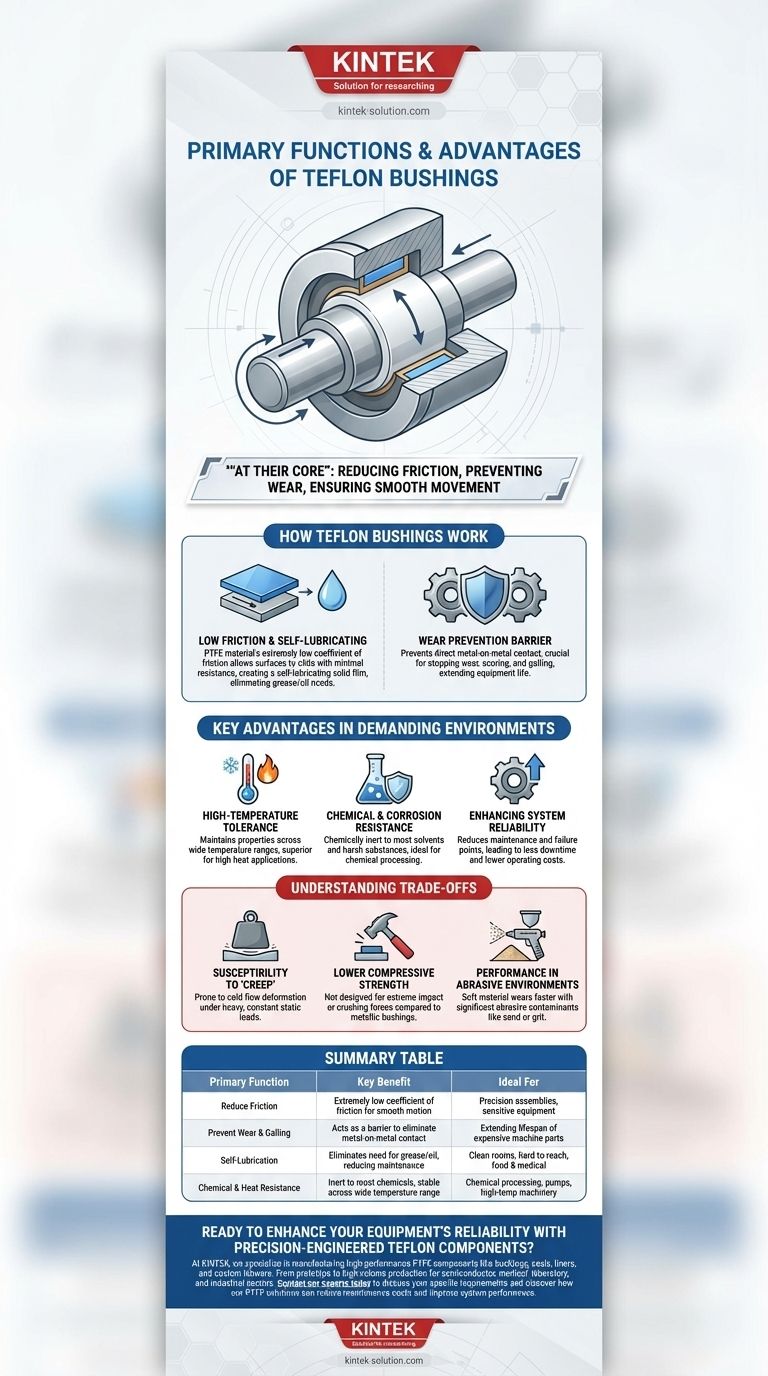

How Teflon Bushings Fundamentally Work

The unique capabilities of these components stem directly from the material they are made of: Polytetrafluoroethylene, or PTFE. This material's molecular structure is the source of its performance advantages.

The Power of Low Friction

A Teflon (PTFE) bushing's defining feature is its extremely low coefficient of friction. This means surfaces can slide against it with minimal resistance.

This property is what allows for smooth, stick-free motion, which is critical for the precision and efficiency of any mechanical assembly.

Self-Lubricating by Design

Because of its slick, non-stick surface, a Teflon bushing is considered self-lubricating. It creates a solid film of lubricant between moving parts.

This completely eliminates the need for oil or grease, which can attract dirt, degrade over time, and require frequent reapplication. This makes them ideal for clean environments or hard-to-reach locations.

Preventing Wear and Galling

By placing a Teflon bushing between two metal components, you prevent direct metal-on-metal contact.

This barrier is crucial for preventing wear, scoring, and galling (a form of wear caused by adhesion between sliding surfaces), thereby preserving the integrity and lifespan of expensive machine parts.

Key Advantages in Demanding Environments

The benefits of Teflon extend beyond just low friction. The material's inherent stability makes it a reliable choice for systems that operate under challenging conditions.

High-Temperature Tolerance

PTFE maintains its structure and low-friction properties across a wide range of temperatures.

This makes Teflon bushings a superior choice for applications involving significant heat, such as in engine components or industrial machinery, where other materials might fail or deform.

Chemical and Corrosion Resistance

Teflon is chemically inert, meaning it does not react with most chemicals, solvents, and corrosive substances.

This resistance makes it indispensable in chemical processing equipment, pumps, and any environment where exposure to harsh substances would destroy traditional metallic or rubber components.

Enhancing System Reliability

By eliminating the need for lubrication and resisting wear, Teflon bushings reduce maintenance requirements and potential points of failure.

This leads to less downtime, lower long-term operating costs, and improved overall equipment reliability.

Understanding the Trade-offs

While highly effective, Teflon bushings are not a universal solution. Understanding their limitations is key to using them correctly.

Susceptibility to "Creep"

Under a heavy, constant load, PTFE can be prone to "creep," or cold flow, where the material slowly deforms over time.

For applications with extremely high static loads, a reinforced PTFE or a different material like a bronze bushing might be more appropriate.

Lower Compressive Strength

Compared to metallic bushings, standard Teflon has lower compressive strength. It is not designed to handle the extreme impact or crushing forces that a steel or bronze bushing can withstand.

Performance in Abrasive Environments

While Teflon prevents friction-related wear, it is a relatively soft material. In environments with significant abrasive contaminants like sand or grit, the bushing itself can wear away more quickly than a hardened metal alternative.

Making the Right Choice for Your Application

Selecting the right bushing requires matching its properties to your primary goal.

- If your primary focus is maintenance reduction and clean operation: A Teflon bushing is an ideal choice, as its self-lubricating nature eliminates the need for external grease or oil.

- If your primary focus is performance in high-temperature or corrosive environments: The inherent chemical and thermal stability of PTFE makes it a superior choice over most traditional materials.

- If your primary focus is supporting extremely high static or impact loads: You should evaluate a metallic bushing or a composite/reinforced PTFE bushing designed for higher strength.

Ultimately, choosing a Teflon bushing is a strategic decision to prioritize reliability, simplified design, and consistent performance in a moving mechanical system.

Summary Table:

| Primary Function | Key Benefit | Ideal For |

|---|---|---|

| Reduce Friction | Extremely low coefficient of friction for smooth motion | Precision assemblies, sensitive equipment |

| Prevent Wear & Galling | Acts as a barrier to eliminate metal-on-metal contact | Extending the lifespan of expensive machine parts |

| Self-Lubrication | Eliminates need for grease or oil, reducing maintenance | Clean rooms, hard-to-reach locations, food & medical |

| Chemical & Heat Resistance | Inert to most chemicals, stable across a wide temperature range | Chemical processing, pumps, high-temperature machinery |

Ready to enhance your equipment's reliability with precision-engineered Teflon components?

At KINTEK, we specialize in manufacturing high-performance PTFE components like bushings, seals, liners, and custom labware. Whether you need a prototype for a new design or high-volume production for the semiconductor, medical, laboratory, or industrial sectors, our commitment to precision and custom fabrication ensures a perfect fit for your application's unique demands.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can reduce your maintenance costs and improve system performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are some standard sizes available for PTFE washers? Find the Perfect Fit for Your Application

- What are the advantages of using glass as a filler in PTFE? Enhance Strength and Wear Resistance

- What industries are PTFE gaskets particularly suitable for? Ideal for Chemical, Pharma, and Food Processing

- What types of industrial applications are Teflon Bellow Mechanical Seals best suited for? Excel in Harsh Chemical & High-Speed Environments

- How does PTFE compare to elastomeric materials for O-rings? A Guide to Extreme Sealing

- What are PTFE mill-type envelope gaskets used for? Seal Critical Flanges in Corrosive & High-Purity Systems

- What temperature range can PTFE expansion bellows withstand? Endure Extremes from -200°C to 260°C

- What are the benefits of advanced PTFE compounds for temperature challenges? Achieve Unmatched Reliability in Extreme Heat