In short, advanced PTFE compounds deliver superior performance under extreme temperatures by integrating specialized fillers that enhance the material's inherent thermal stability. These reinforced formulations maintain their critical mechanical, chemical, and electrical properties across a much broader temperature range than standard PTFE, significantly prolonging service life in demanding applications.

The core benefit is not just surviving heat or cold, but maintaining predictable engineering performance. Advanced PTFE compounds use fillers to bolster the polymer's structure, preventing the degradation, deformation, and loss of strength that standard PTFE would experience under identical thermal stress.

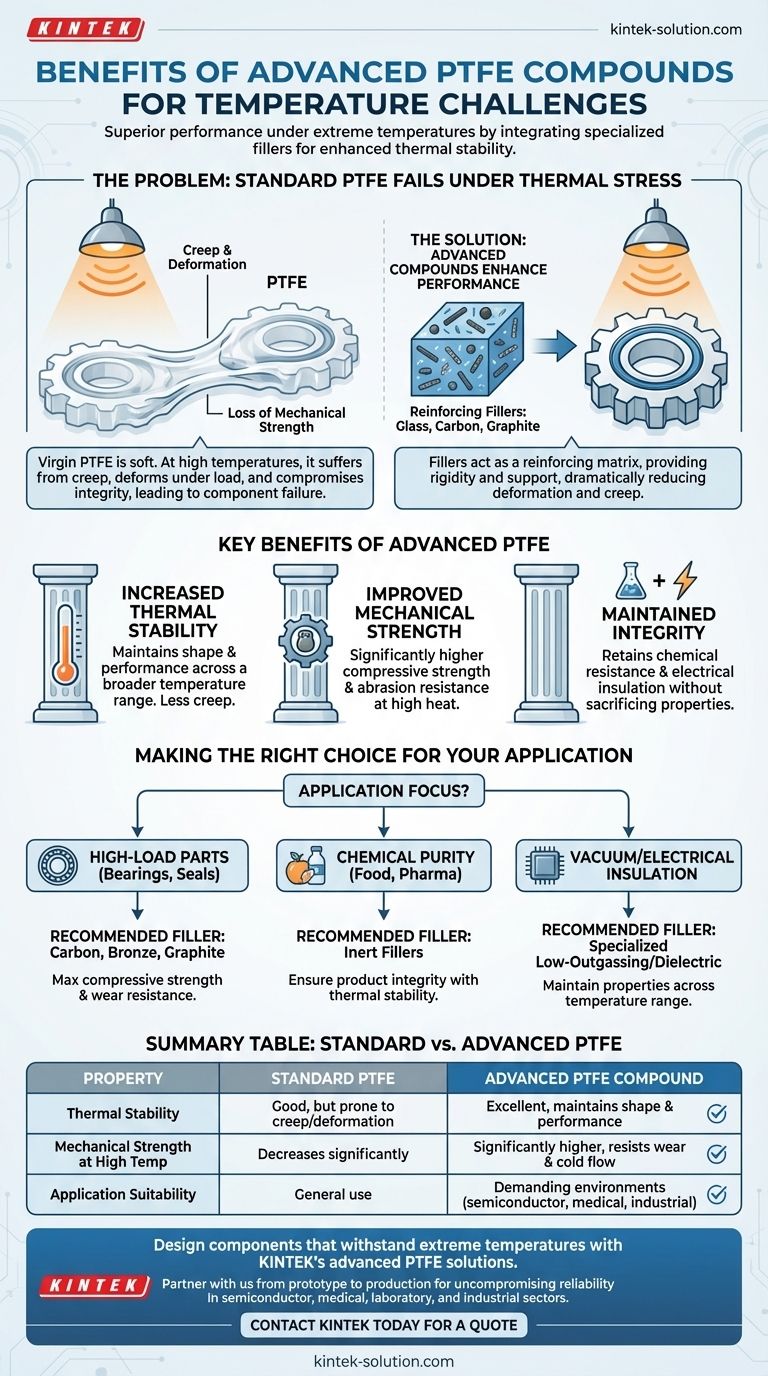

Why Standard PTFE Fails Under Thermal Stress

The Limits of Virgin PTFE

Virgin Polytetrafluoroethylene (PTFE) is known for its impressive operating temperature range. However, it is a relatively soft material.

As temperatures rise, standard PTFE begins to lose its mechanical strength and can be subject to creep or "cold flow," where the material deforms under a sustained load.

Performance Degradation at Extremes

When pushed beyond its optimal limits, the material's integrity is compromised. This leads to component failure in critical applications like seals, gaskets, and bearings, where dimensional stability is paramount.

How Advanced Compounds Enhance Temperature Performance

The solution lies in creating composite materials by adding reinforcing fillers to the PTFE base. These "advanced compounds" are engineered to overcome the limitations of the virgin polymer.

Increased Thermal Stability

Fillers like glass fiber, carbon, or graphite act as a reinforcing matrix within the PTFE. This structure provides rigidity and support, dramatically reducing deformation and creep at elevated temperatures.

This structural enhancement is what allows the compound to withstand a broader range of thermal conditions, ensuring components remain stable and functional.

Improved Mechanical Strength at Temperature

Advanced compounds exhibit significantly higher compressive strength and abrasion resistance compared to virgin PTFE, especially at temperature extremes.

The fillers carry a portion of the mechanical load, allowing parts like bearings and piston cups to operate reliably in high-heat and high-impact environments without premature wear.

Maintained Chemical and Electrical Integrity

A key benefit is that these performance gains are often achieved without sacrificing PTFE's other desirable properties.

Carefully selected fillers ensure the compound retains excellent corrosion resistance and good electrical insulation properties, even when subjected to thermal cycling.

Understanding the Trade-offs

Choosing an advanced compound is not a one-size-fits-all solution. The selection of the filler material is a critical engineering decision that involves balancing performance characteristics.

The Specificity of Fillers

The type of filler directly dictates the compound's final properties. For example, carbon-filled PTFE offers excellent compressive strength and conductivity, while glass-filled PTFE provides enhanced wear resistance.

Impact on Other Properties

Adding a filler can subtly alter some of PTFE's base characteristics. The coefficient of friction may change slightly, or chemical compatibility might be narrowed depending on the filler used.

Understanding the specific application environment—whether it involves harsh chemicals, high loads, or electrical currents—is essential to selecting the optimal compound.

Making the Right Choice for Your Application

To leverage the benefits of advanced PTFE, align the compound's properties with your primary operational challenge.

- If your primary focus is high-load mechanical parts (bearings, seals): Select a compound reinforced with carbon, bronze, or graphite for maximum compressive strength and wear resistance at high temperatures.

- If your primary focus is chemical purity with thermal cycling (food, pharma): Choose a compound with inert fillers that ensure product integrity while providing the necessary thermal stability.

- If your primary focus is vacuum or electrical insulation: Opt for specialized compounds designed for low outgassing or high dielectric strength that maintain these properties across your required temperature range.

Ultimately, selecting the correct advanced PTFE compound is key to designing components that deliver uncompromising reliability in the most demanding thermal environments.

Summary Table:

| Property | Standard PTFE | Advanced PTFE Compound |

|---|---|---|

| Thermal Stability | Good, but prone to creep/deformation | Excellent, maintains shape and performance |

| Mechanical Strength at High Temp | Decreases significantly | Significantly higher, resists wear and cold flow |

| Application Suitability | General use | Demanding environments (semiconductor, medical, industrial) |

Design components that withstand extreme temperatures with KINTEK's advanced PTFE solutions.

If your application in the semiconductor, medical, laboratory, or industrial sector demands reliable performance under thermal stress, KINTEK can help. We specialize in manufacturing precision PTFE components—from custom seals and liners to complex labware—using advanced, filler-reinforced compounds tailored to your specific temperature, chemical, and mechanical requirements.

We partner with you from prototype to high-volume production to ensure your components deliver uncompromising reliability.

Contact KINTEK today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems