In short, the non-stick properties of PTFE impellers are exceptional. They are among the best of any known solid material, stemming directly from PTFE's unique molecular structure and extremely low coefficient of friction. This causes nearly all substances, especially sticky ones like polymers and adhesives, to be repelled from the impeller's surface, which minimizes residue, prevents buildup, and ensures a clean, consistent flow.

The core value of a PTFE impeller's non-stick surface goes beyond simple cleanliness. It is a critical engineering feature that guarantees process integrity, prevents cross-contamination, and maintains hydraulic efficiency when mixing challenging materials.

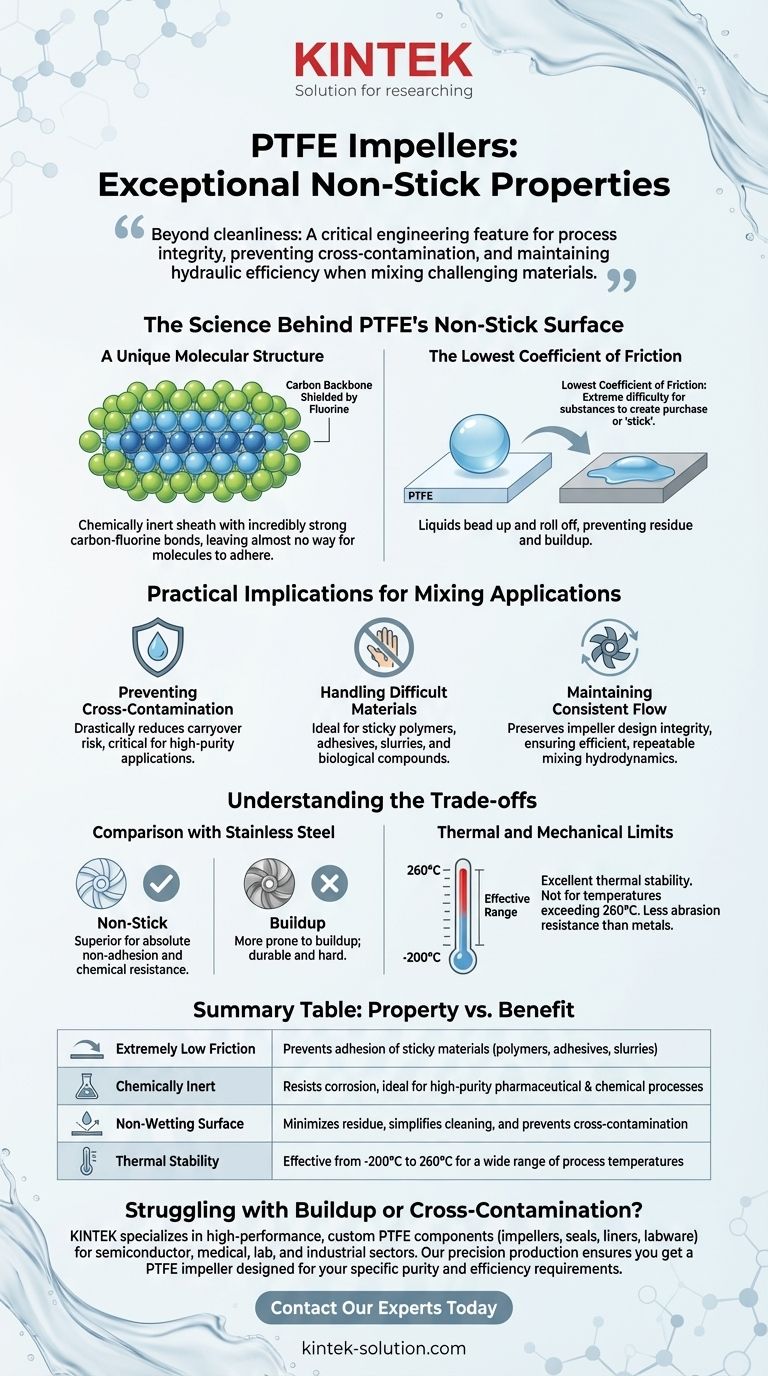

The Science Behind PTFE's Non-Stick Surface

To understand why PTFE (Polytetrafluoroethylene) performs so well, we must look at its fundamental properties at the molecular level.

A Unique Molecular Structure

The non-stick quality of PTFE originates from its chemical composition. It consists of a long chain of carbon atoms completely shielded by a layer of fluorine atoms.

This carbon-fluorine bond is incredibly strong and stable. The fluorine atoms create a tight, uniform, and chemically inert sheath around the carbon backbone, leaving almost no way for other molecules to grab onto the surface.

The Lowest Coefficient of Friction

This molecular structure gives PTFE one of the lowest coefficients of friction of any solid. In practical terms, this means surfaces have extreme difficulty creating purchase or "sticking" to it.

Instead of spreading out, liquids bead up and roll off the surface. This non-wetting characteristic is the key to preventing residue and buildup during mixing operations.

Practical Implications for Mixing Applications

These scientific properties translate directly into significant advantages in industrial, laboratory, and manufacturing settings.

Preventing Cross-Contamination

Because so little material adheres to the impeller, it is remarkably easy to clean. This drastically reduces the risk of carrying material over from one batch to the next, which is critical in pharmaceutical, food, and high-purity chemical applications.

Handling Difficult Materials

PTFE is the ideal choice when working with substances that are inherently sticky. Materials like adhesives, polymers, slurries, and biological compounds are far less likely to build up on a PTFE impeller, ensuring the mixing process remains efficient.

Maintaining Consistent Flow

When material builds up on an impeller, it changes the impeller's shape and weight. This alters the hydrodynamics of the mixing vessel, leading to inefficient or inconsistent results. PTFE's non-stick surface preserves the impeller's design integrity throughout the process.

Understanding the Trade-offs

While its non-stick and chemical properties are world-class, choosing any material involves understanding its complete profile.

Comparison with Stainless Steel

Stainless steel, a common impeller material, is durable and easy to clean in many situations. However, when mixing moderately to highly adhesive compounds, it is significantly more prone to buildup and residue than PTFE.

For applications where absolute non-adhesion is critical, PTFE is the superior choice.

Thermal and Mechanical Limits

PTFE has excellent thermal stability, operating effectively in a wide temperature range from approximately -200°C to 260°C. However, it is not suitable for applications that exceed this upper limit.

Additionally, PTFE is a polymer, not a metal. While robust, it does not possess the same hardness or abrasion resistance as stainless steel, which may be a factor in high-shear environments with abrasive solids.

Making the Right Choice for Your Application

Selecting the correct impeller material depends entirely on your process goals and the materials you are working with.

- If your primary focus is process purity and preventing cross-contamination: PTFE's inert, non-stick surface is the superior choice for minimizing residue between batches.

- If you are working with sticky or viscous materials like adhesives or polymers: The low coefficient of friction of a PTFE impeller will ensure consistent mixing and prevent product buildup.

- If your priority is mechanical durability in a high-abrasion environment: You may need to evaluate the trade-off between PTFE's non-stick benefits and the superior hardness of a material like stainless steel.

By understanding the fundamental properties of PTFE, you can confidently select the right tool to ensure an efficient, pure, and repeatable process.

Summary Table:

| Property | Benefit for Mixing Applications |

|---|---|

| Extremely Low Friction | Prevents adhesion of sticky materials (polymers, adhesives, slurries) |

| Chemically Inert | Resists corrosion, ideal for high-purity pharmaceutical & chemical processes |

| Non-Wetting Surface | Minimizes residue, simplifies cleaning, and prevents cross-contamination |

| Thermal Stability | Effective from -200°C to 260°C for a wide range of process temperatures |

Struggling with material buildup or cross-contamination in your mixing process?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including impellers, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a PTFE impeller designed for your specific application's purity and efficiency requirements.

Contact our experts today to discuss how a KINTEK PTFE impeller can solve your sticking problems and enhance your process integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications