In short, PTFE lined valves are a cornerstone of modern industrial safety and purity. They are predominantly utilized in the chemical processing, pharmaceutical, food and beverage, water treatment, and semiconductor manufacturing industries. These sectors rely on them to handle highly corrosive, toxic, or ultra-pure media without risk of corrosion, system failure, or product contamination.

The core reason these industries universally adopt PTFE lined valves is not just for the valve itself, but for what the PTFE lining provides: a near-universal barrier against chemical attack, ensuring both the integrity of the equipment and the purity of the substance passing through it.

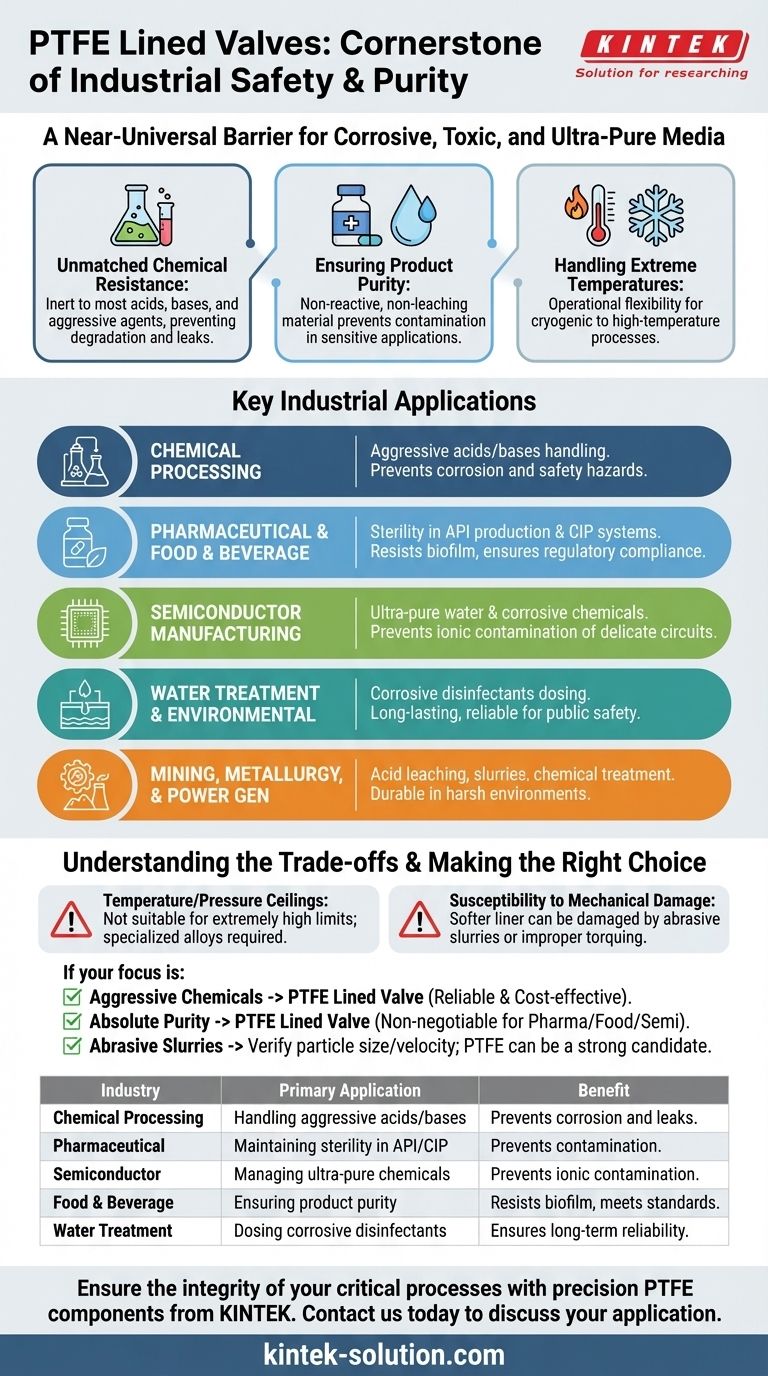

Why These Industries Rely on PTFE Lining

The selection of a PTFE lined valve is a strategic decision rooted in managing operational risk and maintaining product quality. The unique properties of Polytetrafluoroethylene (PTFE) directly address the most severe challenges faced in these demanding environments.

Unmatched Chemical Resistance

PTFE is a fluoropolymer with exceptional chemical inertness. It is virtually unaffected by most known chemicals, acids, and bases, making it the ideal material for handling aggressive and corrosive media.

This resistance prevents the valve's metal body from degrading, which would otherwise lead to leaks, costly downtime, and significant safety hazards.

Ensuring Product Purity

In industries like pharmaceuticals, food production, and semiconductor manufacturing, even microscopic contamination can ruin an entire batch.

Because PTFE is a highly stable and non-reactive material, it does not leach or shed particles into the media. This ensures the fluid remains pure and meets stringent quality standards, such as those for Active Pharmaceutical Ingredients (APIs) or ultra-pure water systems.

Handling Extreme Temperatures

PTFE lined valves can operate across a wide temperature range, successfully managing both cryogenic fluids and high-temperature processes.

This thermal stability provides operational flexibility, allowing a single valve type to be standardized across various stages of a production line that may involve heating or cooling cycles.

A Closer Look at Key Industrial Applications

While the principles are universal, the specific application of PTFE lined valves highlights their importance in different sectors.

Chemical and Petrochemical Processing

This is the primary domain for PTFE lined valves. They are used in reactors, mixing tanks, and transfer lines for aggressive substances like sulfuric acid, chlorine, and other caustic agents.

The valves' reliability is critical for maintaining process safety and preventing environmental incidents.

Pharmaceutical and Food & Beverage

In these highly regulated industries, the focus is on preventing contamination. PTFE lined valves are essential in Clean-in-Place (CIP) systems, API production, and the handling of sensitive ingredients.

Their smooth, non-stick surface resists biofilm buildup and ensures that processes remain sterile and compliant with regulatory standards.

Semiconductor Manufacturing

The production of microchips requires ultra-pure water and highly corrosive chemicals for etching wafers.

PTFE lined components are mandatory to prevent ionic contamination that would destroy the delicate electronic circuits. They protect both the product and the sophisticated manufacturing equipment.

Water Treatment and Environmental Protection

Municipal and industrial water treatment facilities handle a variety of corrosive chemicals for disinfection and pH balancing, such as chlorine and sodium hydroxide.

PTFE lined valves offer a long-lasting, reliable solution for managing these chemicals, ensuring the safety and efficiency of public and environmental health systems.

Mining, Metallurgy, and Power Generation

These heavy industries often involve acid leaching, slurries, and chemical treatment processes. PTFE lined valves are used in applications like acid recovery systems and electroplating where corrosive mixtures are common.

Their durability in these harsh environments makes them a cost-effective choice over more expensive exotic alloys.

Understanding the Trade-offs

While highly effective, PTFE lined valves are not a universal solution. An objective assessment requires understanding their limitations.

Temperature and Pressure Ceilings

Although PTFE has a wide operating temperature range, it has distinct limits. It is not suitable for extremely high-temperature or high-pressure applications where specialized metal alloys would be required. Exceeding these ratings can cause the liner to fail.

Susceptibility to Mechanical Damage

The PTFE liner, while chemically robust, is mechanically softer than metal. It can be damaged by severe abrasive slurries containing sharp particles or by improper installation and maintenance, such as over-torquing bolts.

This can lead to liner delamination or tearing, compromising the valve's integrity.

Making the Right Choice for Your Application

Selecting the correct valve is about matching the material's strengths to your primary operational goal.

- If your primary focus is handling highly aggressive chemicals: A PTFE lined valve is almost always the most reliable and cost-effective choice for ensuring long-term safety and preventing corrosion.

- If your primary focus is maintaining absolute product purity: The non-reactive, non-leaching surface of PTFE is non-negotiable for pharmaceutical, semiconductor, or food-grade applications.

- If your primary focus is managing abrasive slurries with corrosive elements: A PTFE lined valve is a strong candidate, but you must verify that the particle size and velocity will not mechanically damage the liner.

Ultimately, specifying a PTFE lined valve is a strategic investment in the safety, purity, and long-term reliability of your critical fluid handling systems.

Summary Table:

| Industry | Primary Application & Benefit |

|---|---|

| Chemical Processing | Handling aggressive acids/bases; prevents corrosion and leaks. |

| Pharmaceutical | Maintaining sterility in API production and CIP systems; prevents contamination. |

| Semiconductor | Managing ultra-pure chemicals; prevents ionic contamination of wafers. |

| Food & Beverage | Ensuring product purity; resists biofilm and meets regulatory standards. |

| Water Treatment | Dosing corrosive disinfectants; ensures long-term reliability and safety. |

Ensure the integrity of your critical processes with precision PTFE components from KINTEK.

Whether you operate in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE seals, liners, labware, and valves are engineered to handle your most aggressive and pure media. From initial prototypes to high-volume production, we prioritize precision manufacturing to deliver solutions that protect your equipment and your product.

Contact KINTEK today to discuss your specific application requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications