At their core, PTFE envelope gaskets provide the exceptional chemical resistance of solid PTFE combined with the mechanical strength and resilience of a separate core material. This composite design allows them to create a reliable, non-contaminating seal in chemically aggressive environments where a simpler gasket would quickly fail.

The central benefit of a PTFE envelope gasket is its ability to deliver elite chemical performance without the primary drawback of solid PTFE. By encasing a compressible insert, it resists the "creep" or "cold flow" that can cause solid PTFE gaskets to loosen under bolt pressure over time.

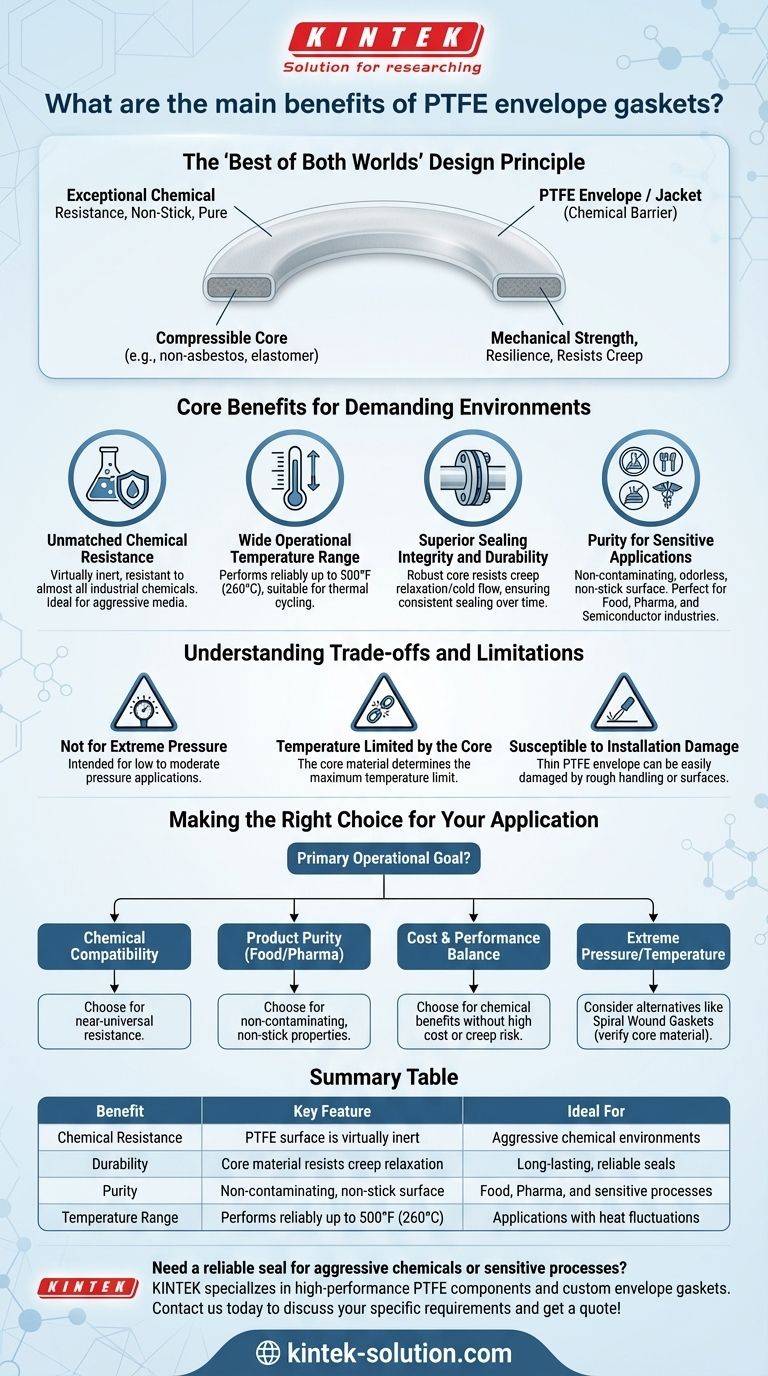

The "Best of Both Worlds" Design Principle

To understand the benefits, you must first understand the construction. A PTFE envelope gasket is not a single material but a clever combination of two.

What is a PTFE Envelope Gasket?

A PTFE envelope gasket consists of a core insert material (such as compressed non-asbestos fiber or a specific elastomer) that is wrapped in a thin, protective "envelope" or jacket of Polytetrafluoroethylene (PTFE).

The PTFE is the only material that comes into contact with the process media. The inner core material provides the mechanical force and resilience needed to maintain a tight seal against the flange faces.

Combining Chemical Purity with Mechanical Strength

This design strategically separates tasks. The PTFE envelope provides the chemically inert, non-stick surface, while the core material delivers the compressibility and structural integrity required for a durable seal under bolt load.

This allows the gasket to conform to flange imperfections and maintain sealing pressure, overcoming the inherent limitations of using solid PTFE alone.

Core Benefits for Demanding Environments

The unique construction of PTFE envelope gaskets makes them a go-to solution for specific and challenging industrial applications.

Unmatched Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals and solvents. This makes the gasket suitable for aggressive media where other elastomers or fibers would degrade, swell, or dissolve.

This "near-universal" chemical compatibility simplifies gasket selection and reduces the risk of chemical-related seal failure.

Wide Operational Temperature Range

These gaskets perform reliably across a broad spectrum of temperatures, typically up to 500°F (260°C). This makes them ideal for processes that involve significant heat fluctuations or thermal cycling.

The exact temperature rating, however, is often determined by the core material, not just the PTFE envelope itself.

Superior Sealing Integrity and Durability

The robust core provides excellent compressibility and adaptability to the flange surface. More importantly, it resists creep relaxation (also known as cold flow), a phenomenon where solid PTFE gaskets can slowly deform and lose their sealing pressure under a constant bolt load.

This ensures a more consistent and reliable seal throughout the gasket's service life, reducing the need for frequent re-torquing or replacement.

Purity for Sensitive Applications

The PTFE surface is non-contaminating, odorless, and has excellent non-stick properties. This prevents process media from adhering to the gasket, simplifying cleaning and preventing batch contamination.

These qualities are critical in food, beverage, and pharmaceutical industries where product purity is non-negotiable.

Understanding the Trade-offs and Limitations

While highly effective, PTFE envelope gaskets are not a universal solution. Understanding their limitations is key to using them correctly.

Not for Extreme Pressure

While robust, these gaskets are generally intended for low to moderate pressure applications. In extremely high-pressure systems, a metallic or semi-metallic gasket, such as a spiral wound gasket, is typically the more appropriate choice.

Temperature is Limited by the Core

The PTFE envelope may be rated for high temperatures, but the gasket's overall operational temperature limit is dictated by the weakest link, which is often the core material. An EPDM rubber core, for instance, will have a much lower maximum temperature than a compressed fiber core.

Susceptible to Installation Damage

The PTFE envelope is relatively thin. It can be easily scratched, dented, or torn by rough flange surfaces, improper handling, or over-compression. Any breach in the envelope will expose the core material to the process media, leading to rapid failure.

Making the Right Choice for Your Application

Selecting the right gasket requires matching its benefits to your primary operational goal.

- If your primary focus is chemical compatibility: The near-universal resistance of the PTFE surface makes this one of the safest and most reliable choices for aggressive media.

- If your primary focus is product purity (food/pharma): The non-contaminating, non-stick, and odorless nature of the PTFE envelope is ideal for preventing contamination.

- If your primary focus is balancing cost and performance: Envelope gaskets offer the chemical benefits of solid PTFE without the high cost or the significant risk of creep failure under load.

- If your primary focus is extreme pressure or temperature: You must verify that the gasket's core material meets your specifications and strongly consider alternatives like spiral wound gaskets for the most severe conditions.

Ultimately, a PTFE envelope gasket is an engineered solution that delivers elite chemical resistance and purity by intelligently combining materials to meet specific operational demands.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Chemical Resistance | PTFE surface is virtually inert | Aggressive chemical environments |

| Durability | Core material resists creep relaxation | Long-lasting, reliable seals |

| Purity | Non-contaminating, non-stick surface | Food, Pharma, and sensitive processes |

| Temperature Range | Performs reliably up to 500°F (260°C) | Applications with heat fluctuations |

Need a reliable seal for aggressive chemicals or sensitive processes?

KINTEK specializes in manufacturing high-performance PTFE components, including custom envelope gaskets. We provide the precision and chemical resistance your application demands, from prototypes to high-volume orders for the semiconductor, medical, laboratory, and industrial sectors.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications