The primary advantages of PTFE bushes are their extremely low friction, inherent self-lubricating properties, and exceptional resistance to chemicals and high temperatures. Unlike traditional metal bushings that require regular lubrication and are susceptible to corrosion, or other plastic bushings that may not withstand harsh conditions, PTFE provides a maintenance-free, highly durable solution for demanding applications.

The core decision to use a PTFE bush is not about replacing every traditional bushing, but about solving specific engineering problems. PTFE excels where friction, chemical exposure, or maintenance are critical points of failure for conventional materials.

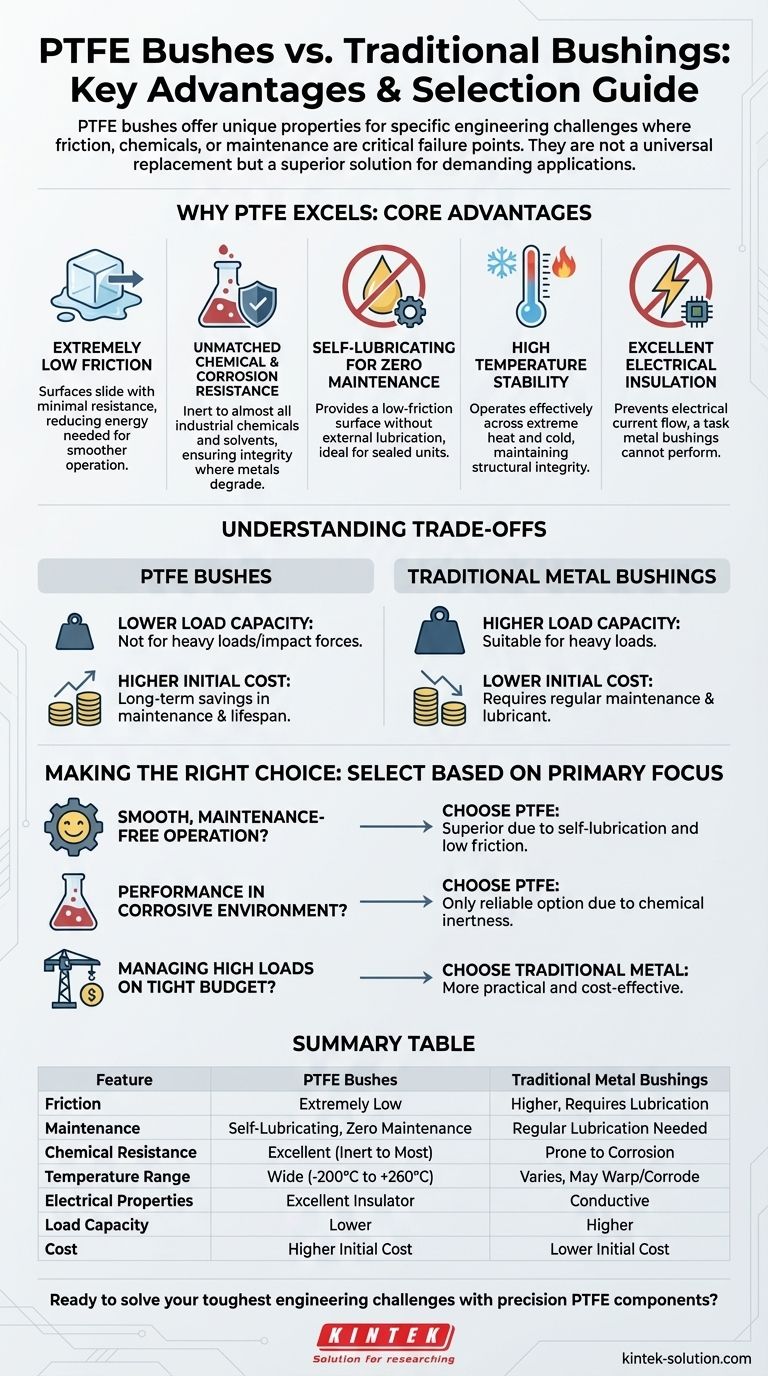

Why PTFE Excels: Core Advantages Explained

Polytetrafluoroethylene (PTFE) is an engineered polymer with a unique set of properties. Understanding these attributes is key to knowing when to specify a PTFE bush for your application.

The Power of Low Friction

A key feature of PTFE is its exceptionally low coefficient of friction. This means surfaces slide against it with very little resistance.

This property translates directly to smoother, more efficient mechanical movement and can significantly reduce the energy required to operate a system.

Unmatched Chemical and Corrosion Resistance

PTFE is chemically inert to almost all industrial chemicals and solvents.

Where a metal bushing would corrode or degrade when exposed to acids, bases, or aggressive cleaning agents, a PTFE bush remains completely unaffected, ensuring operational integrity in harsh environments.

Self-Lubricating for Zero Maintenance

PTFE bushes are self-lubricating. The material itself provides a low-friction surface without the need for external grease or oil.

This eliminates the need for regular maintenance schedules, making them ideal for sealed units, food processing equipment, or hard-to-reach locations where lubrication is impractical or undesirable.

High Temperature Stability

PTFE maintains its structural integrity and performance characteristics across a very wide temperature range.

It can operate effectively in extreme heat where many other plastic bushings would melt or deform, and in cold where others might become brittle.

Excellent Electrical Insulation

As a polymer, PTFE is a fantastic electrical insulator.

This property makes it the ideal choice for applications where the bushing must prevent the flow of electrical current between components, a task metal bushings cannot perform.

Understanding the Trade-offs

While its advantages are significant, PTFE is not the universal solution for every application. Objective analysis requires acknowledging its limitations.

Load Capacity

Traditional metal bushings (like bronze or steel) generally offer a much higher load-bearing capacity than PTFE.

For applications involving extremely heavy loads or high impact forces, a metallic bushing is often the more appropriate and durable choice.

Initial Cost

PTFE bushes typically have a higher upfront cost compared to many common metal or standard plastic bushings.

However, this initial investment is often justified by long-term savings from eliminated maintenance, reduced downtime, and a longer service life in corrosive or high-friction environments.

Making the Right Choice for Your Application

Selecting the correct bushing material requires you to clearly define the most critical demands of your specific engineering goal.

- If your primary focus is smooth, maintenance-free operation: PTFE is the superior choice due to its self-lubricating properties and low friction.

- If your primary focus is performance in a corrosive or chemical environment: PTFE's chemical inertness makes it the only reliable option over metal.

- If your primary focus is managing high loads on a tight budget: A traditional metal bushing is likely the more practical and cost-effective solution.

Ultimately, choosing the right material is about matching its unique strengths to your most pressing operational challenges.

Summary Table:

| Feature | PTFE Bushes | Traditional Metal Bushings |

|---|---|---|

| Friction | Extremely Low | Higher, Requires Lubrication |

| Maintenance | Self-Lubricating, Zero Maintenance | Regular Lubrication Needed |

| Chemical Resistance | Excellent (Inert to Most Chemicals) | Prone to Corrosion |

| Temperature Range | Wide (-200°C to +260°C) | Varies by Metal, May Warp or Corrode |

| Electrical Properties | Excellent Insulator | Conductive |

| Load Capacity | Lower | Higher |

| Cost | Higher Initial Cost | Lower Initial Cost |

Ready to solve your toughest engineering challenges with precision PTFE components?

KINTEK specializes in manufacturing high-performance PTFE bushes, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your application's unique demands.

Contact KINTEK today to discuss how our PTFE solutions can enhance your equipment's performance, reduce maintenance, and extend service life.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments