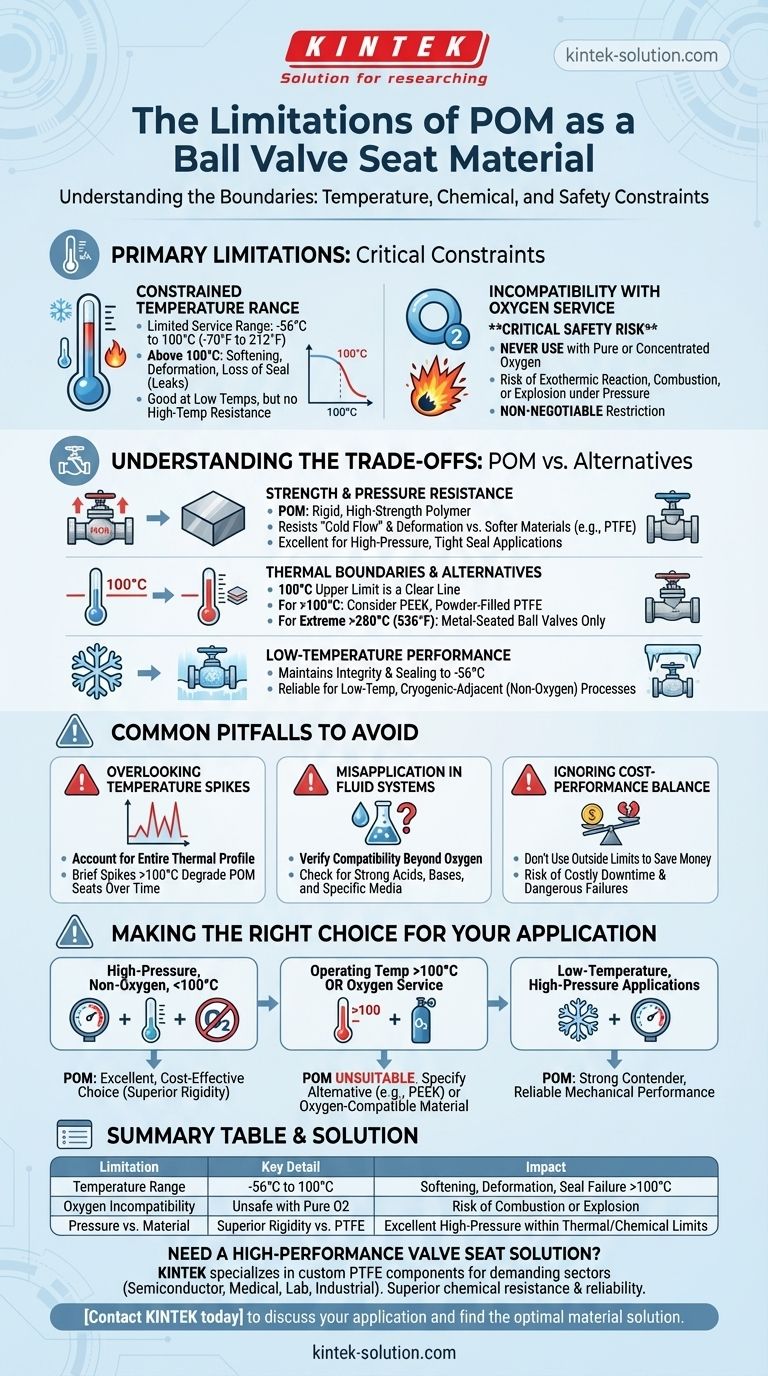

The primary limitations of POM as a ball valve seat material are its relatively narrow operating temperature range and its critical incompatibility with oxygen service. While an excellent material for specific high-pressure scenarios, these two factors strictly define its appropriate use cases.

The core decision hinges on a trade-off: POM offers superior rigidity and high-pressure performance compared to materials like PTFE, but only within a tightly controlled thermal and chemical environment. Understanding these boundaries is essential for ensuring system safety and reliability.

The Core Limitations of POM Explained

To properly apply POM (Polyoxymethylene), also known as Acetal or Delrin, you must respect its operational limits. Ignoring them can lead to catastrophic valve failure.

Constrained Temperature Range

POM has a specific and limited service temperature range, typically from -56°C to 100°C (-70°F to 212°F).

Exceeding the upper limit can cause the material to soften, deform, and lose its sealing capability, leading to leaks. While it performs well at low temperatures, it lacks the high-temperature resistance of other polymers or metal seats.

Incompatibility with Oxygen Service

This is the most critical safety limitation. POM must never be used in applications involving pure or concentrated oxygen flow.

The material can react exothermically with oxygen, especially under pressure, creating a significant risk of combustion or explosion. This restriction is non-negotiable for any system designer or engineer.

Understanding the Trade-offs: POM vs. Other Seat Materials

Choosing a seat material is never about finding one "best" option; it's about finding the right option for the specific application. POM's limitations are best understood in comparison to other common choices.

Strength and Pressure Resistance

POM is a rigid, high-strength polymer. This gives it a significant advantage over softer materials like PTFE, which can be susceptible to "cold flow" or deformation under high pressure and over time.

This makes POM an excellent choice for high-pressure applications where maintaining a tight seal without material extrusion is the primary concern.

Thermal Boundaries and Alternatives

The 100°C upper limit for POM is a clear dividing line. For applications requiring higher temperatures, other materials must be considered.

Specialty polymers like PEEK or powder-filled PTFE are used to increase the maximum service temperature. For extreme conditions, typically those exceeding 280°C (536°F), only metal-seated ball valves are suitable.

Low-Temperature Performance

While its upper temperature range is limited, POM's performance in cold environments is a key strength.

It maintains its structural integrity and sealing capability down to -56°C, making it a reliable choice for certain low-temperature and cryogenic-adjacent processes where oxygen is not present.

Common Pitfalls to Avoid

Misunderstanding POM's limitations is a common source of valve failure. Be aware of these frequent mistakes.

Overlooking Temperature Spikes

Engineers must account for the entire thermal profile of the system, not just the average operating temperature. Brief but frequent temperature spikes above 100°C can degrade POM seats over time, leading to premature failure.

Misapplication in Fluid Systems

While this article focuses on oxygen, POM has other chemical incompatibilities. Always verify that the material is compatible with the specific media being used in your system, especially strong acids or bases.

Ignoring the Cost-Performance Balance

POM is often selected for its balance of performance and cost. However, attempting to use it just outside its specified limits to save money is a false economy that can result in costly system downtime or dangerous failures.

Making the Right Choice for Your Application

Select your valve seat material based on the non-negotiable demands of your system.

- If your primary focus is high-pressure service in a non-oxygen system below 100°C: POM is an excellent and cost-effective choice due to its superior rigidity and resistance to cold flow.

- If your primary focus is operating temperatures above 100°C or any oxygen service: POM is unsuitable. You must specify an alternative like PEEK for higher temperatures or a material explicitly rated for oxygen compatibility.

- If your primary focus is low-temperature, high-pressure applications: POM is a very strong contender, offering reliable mechanical performance where other polymers might become brittle.

Ultimately, leveraging POM's strengths requires a clear understanding of its precise operational boundaries.

Summary Table:

| Limitation | Key Detail | Impact |

|---|---|---|

| Temperature Range | -56°C to 100°C (-70°F to 212°F) | Softening, deformation, and seal failure above 100°C |

| Oxygen Incompatibility | Unsafe with pure or concentrated oxygen | Risk of combustion or explosion |

| Pressure vs. Material Trade-off | Superior rigidity vs. PTFE, resists cold flow | Excellent for high-pressure, but within strict thermal/chemical limits |

Need a High-Performance Valve Seat Solution?

POM's limitations are critical for system safety. For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, you need a material that meets your exact requirements.

KINTEK specializes in custom PTFE components—including seals, liners, and labware—that offer superior chemical resistance and reliability. Whether you need prototypes or high-volume orders, our precision manufacturing ensures your valves perform safely and efficiently.

Contact KINTEK today to discuss your application and find the optimal material solution for your ball valve seats.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What advantages do PTFE coatings offer in terms of durability and maintenance? Maximize Component Lifespan

- What are the shapes and dimensions of PTFE sliding bearing pads? Rectangular & Circular Load Solutions

- What are the durability benefits of PTFE washers? Achieve Unmatched Chemical & Thermal Resistance

- Why are PTFE rods suitable for medical applications? Unmatched Safety and Sterilization Performance

- What are the common applications of graphite packing? Master Sealing for Extreme Conditions

- What are the two types of PTFE rods and their general applications? Choose the Right PTFE for Your Project

- What are the two common application methods for PTFE in slide bearings? A Guide to Linear and Rotational Movement

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs