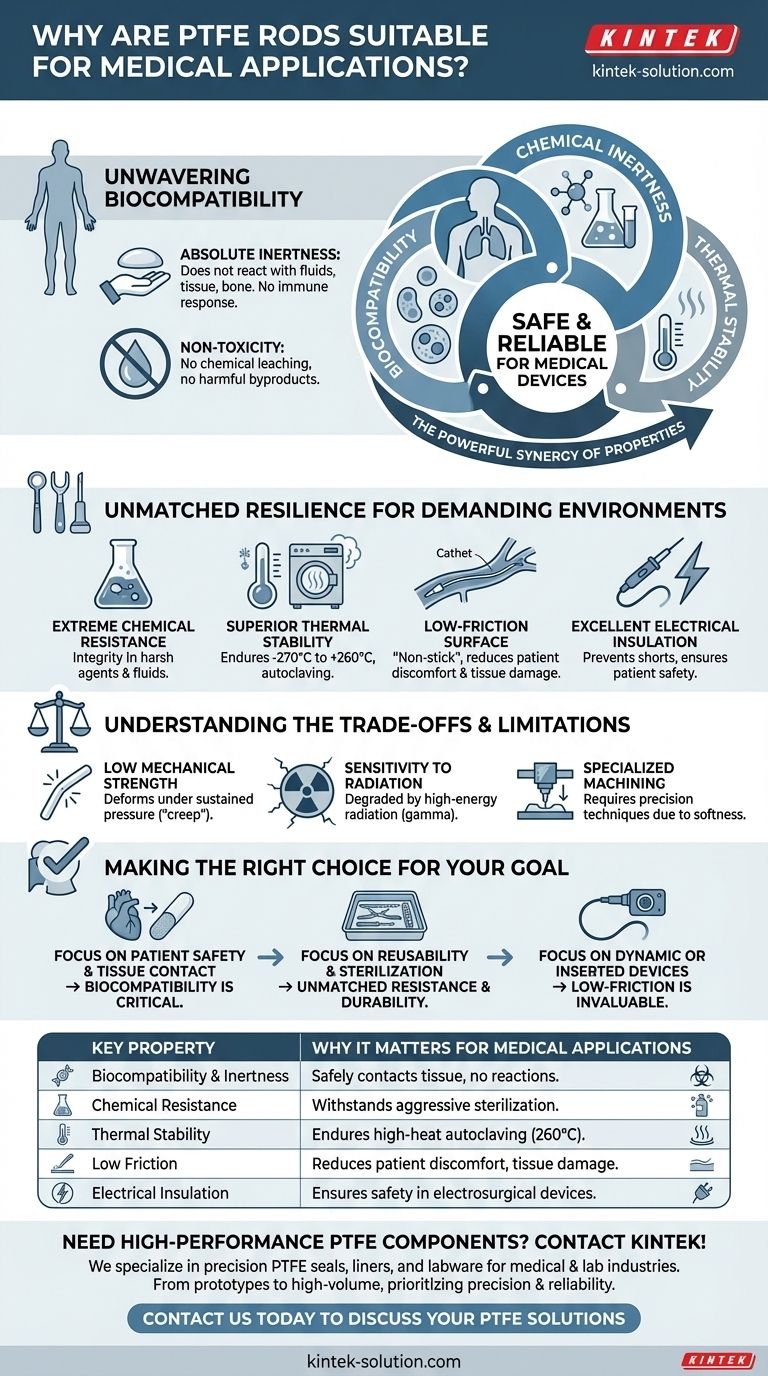

At its core, PTFE rods are suitable for medical applications because they are profoundly unreactive. This unique combination of biocompatibility, chemical inertness, and thermal stability means they can be safely used in contact with human tissue and can withstand rigorous sterilization processes without degrading or releasing harmful substances.

The decision to use PTFE in medicine isn't based on a single feature, but on the powerful synergy of its properties. Its fundamental inability to react with its environment—be it human tissue, aggressive chemicals, or high heat—makes it one of the safest and most reliable polymers for critical medical devices.

The Foundation: Unwavering Biocompatibility

The primary requirement for any material used inside the body is that it does no harm. PTFE excels in this regard through its complete biological inertness.

Absolute Inertness

PTFE is one of the most inert materials known. It does not react with bodily fluids, tissue, or bone, which prevents adverse immune responses or rejection.

Non-Toxicity

This material is fundamentally non-toxic and non-allergenic. It does not leach chemicals or break down into harmful byproducts when implanted or used in medical equipment.

Unmatched Resilience for Demanding Environments

Medical applications require materials that can withstand not only the internal environment of the body but also the external processes of cleaning and sterilization.

Extreme Chemical Resistance

PTFE is resistant to a vast range of aggressive chemicals. This ensures the material's integrity is not compromised by bodily fluids or harsh sterilization agents.

Superior Thermal Stability

With a working temperature range from -270°C to +260°C, PTFE easily endures common sterilization methods like autoclaving (steam sterilization), which involves high heat and pressure.

Low-Friction Surface

PTFE possesses one of the lowest coefficients of friction of any solid. This "non-stick" quality is critical for devices like catheters, reducing patient discomfort and minimizing tissue damage during insertion and removal.

Excellent Electrical Insulation

As a superior dielectric material, PTFE is used to insulate components in sophisticated medical machinery and electrosurgical devices, preventing electrical shorts and ensuring patient safety.

Understanding the Trade-offs and Limitations

While its properties are exceptional, PTFE is not a universal solution. Acknowledging its limitations is key to successful application.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for load-bearing structural implants as it can deform under sustained pressure, a phenomenon known as "creep."

Sensitivity to Radiation

While PTFE handles steam sterilization well, it can be degraded by high-energy radiation, such as gamma sterilization. This can compromise its mechanical properties and must be considered during device design.

Specialized Machining

The softness of PTFE means that machining it into precise components requires specialized techniques and tooling to achieve tight tolerances without deforming the material.

Making the Right Choice for Your Goal

Selecting PTFE is a strategic decision based on the specific demands of the medical application.

- If your primary focus is patient safety and direct tissue contact: PTFE's biocompatibility and inertness are its most critical, non-negotiable features.

- If your primary focus is device reusability and sterilization: Its unmatched resistance to both chemicals and high temperatures makes it a durable and reliable choice.

- If your primary focus is on dynamic or inserted devices: The extremely low-friction surface is invaluable for minimizing tissue interaction and improving patient comfort.

Ultimately, choosing PTFE is a decision rooted in maximizing safety and performance within the uncompromising environment of modern medicine.

Summary Table:

| Key Property | Why It Matters for Medical Applications |

|---|---|

| Biocompatibility & Inertness | Safely contacts tissue and bodily fluids without causing reactions or toxicity. |

| Chemical Resistance | Withstands aggressive sterilization agents and bodily fluids without degrading. |

| Thermal Stability | Endures autoclaving and high-temperature sterilization (up to 260°C). |

| Low Friction | Reduces patient discomfort and tissue damage in devices like catheters. |

| Electrical Insulation | Ensures safety in electrosurgical devices and medical machinery. |

Need High-Performance PTFE Components for Your Medical Device?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the medical, semiconductor, and laboratory industries. Our expertise ensures your devices benefit from PTFE's critical properties, such as superior biocompatibility and sterilization resilience.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and reliability for your most demanding applications.

Contact us today to discuss how our PTFE solutions can enhance the safety and performance of your medical products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What precautions should be taken when handling PTFE gaskets? Ensure Longevity & Performance

- What is the advantage of using spread/flat glass reinforcement in PTFE laminates? Achieve Superior Signal Integrity for High-Frequency Electronics

- What are the key properties of PTFE that make it suitable for bushes? Discover the Ultimate Self-Lubricating Solution

- What is the role of bearing pads in civil engineering? The Critical Interface for Structural Integrity

- What are the advantages of using PTFE bushes? Low-Friction, Chemical-Resistant Performance

- What materials are used to manufacture PTFE bars? A Guide to Virgin & Filled PTFE

- What industries commonly use PTFE seals? The Ultimate Guide for High-Performance Applications

- What factors should be considered when choosing between PTFE and NBR oil seals? Select the Right Seal for Your Application