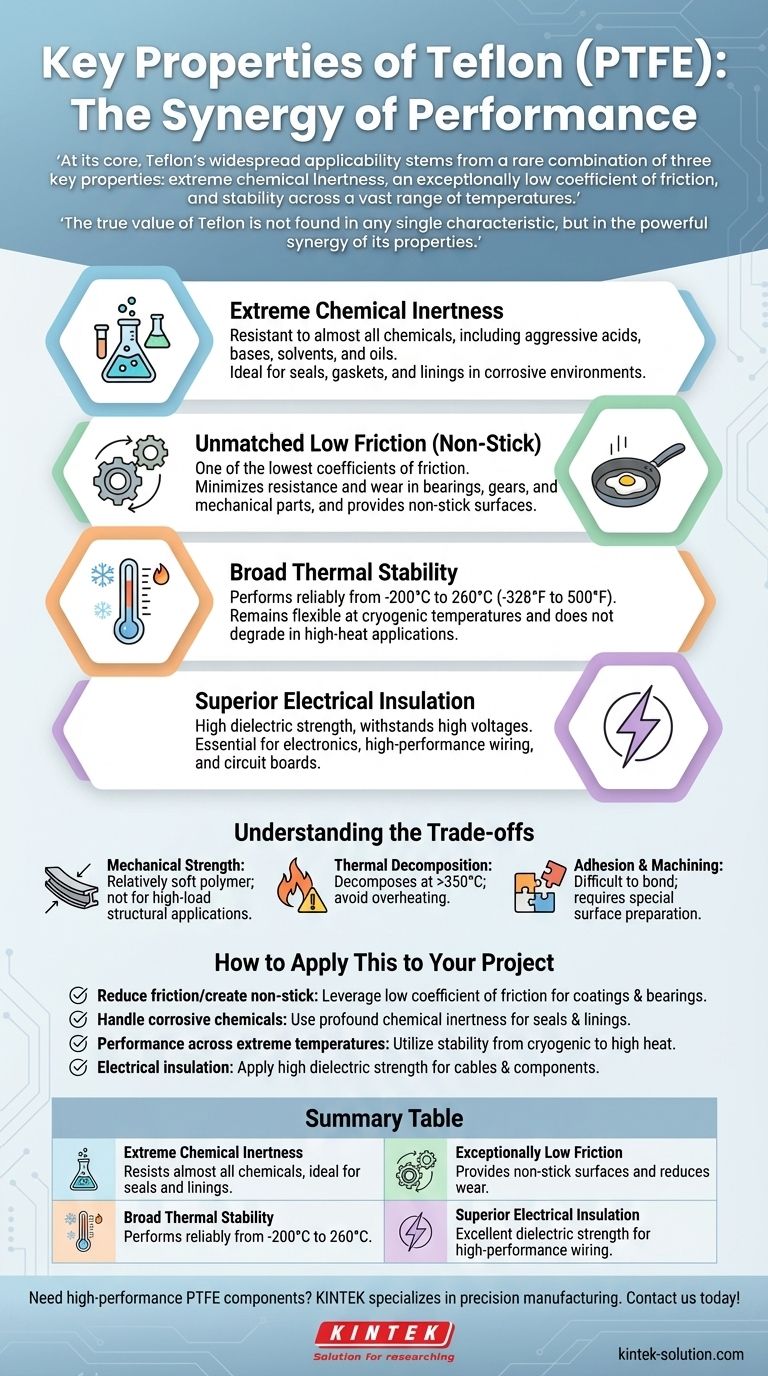

At its core, Teflon's widespread applicability stems from a rare combination of three key properties: extreme chemical inertness, an exceptionally low coefficient of friction, and stability across a vast range of temperatures. Formally known as Polytetrafluoroethylene (PTFE), this synthetic fluoropolymer is uniquely suited for environments where other materials would quickly degrade, stick, or fail.

The true value of Teflon is not found in any single characteristic, but in the powerful synergy of its properties. It solves engineering challenges by being simultaneously non-reactive, non-stick, and thermally resilient, a combination few other materials can offer.

Deconstructing the Core Properties of Teflon

To understand why Teflon appears in everything from aerospace components to medical devices, we must examine the practical impact of its fundamental characteristics.

Extreme Chemical Inertness

Teflon is exceptionally non-reactive. Its molecular structure, built on a strong backbone of carbon and fluorine atoms, makes it resistant to almost all chemicals, including aggressive acids, bases, solvents, and oils.

This inertness makes it an invaluable material for creating seals, gaskets, and linings in chemical processing plants and laboratories where contact with corrosive substances is constant.

Unmatched Low Friction (Non-Stick)

Teflon possesses one of the lowest coefficients of friction of any known solid material. This is the scientific principle behind its famous "non-stick" quality.

This property is critical not only for consumer cookware but also for industrial applications. It is used as a coating on bearings, gears, and other mechanical parts to reduce wear and energy consumption by minimizing resistance.

Broad Thermal Stability

Teflon performs reliably across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F). It remains flexible at cryogenic temperatures and does not degrade in high-heat applications within its service range.

This makes it suitable for extreme environments, from seals in liquid nitrogen systems to insulation in high-temperature industrial processes.

Superior Electrical Insulation

As a material, Teflon does not conduct electricity and has a very high dielectric strength. This means it can withstand high voltages without breaking down.

This property is essential for the electronics industry, where it is used as an insulating material for high-performance wiring, cables, and circuit boards, particularly in high-frequency applications.

Understanding the Trade-offs

While its properties are remarkable, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations.

Mechanical Strength

Teflon is a relatively soft polymer. It is not intended for high-load structural applications where materials like steel or aluminum are required. It can be susceptible to "creep," or slow deformation, under a sustained load.

Thermal Decomposition

While stable up to 260°C (500°F), Teflon will begin to decompose at significantly higher temperatures (around 350°C / 662°F). This is a critical safety consideration, particularly in applications like cookware, where overheating must be avoided.

Adhesion and Machining

The same non-stick, inert properties that make Teflon so useful also make it difficult to bond to other materials. Special surface preparation techniques are required to make adhesives work effectively.

How to Apply This to Your Project

Your choice to use Teflon should be directly tied to the primary problem you are trying to solve.

- If your primary focus is reducing friction or creating a non-stick surface: Teflon's extremely low coefficient of friction is the ideal property to leverage for coatings, bearings, or self-lubricating parts.

- If your primary focus is handling corrosive chemicals: Its profound chemical inertness makes it the definitive choice for seals, linings, and tubing in aggressive environments.

- If your primary focus is performance across extreme temperatures: Its stability from cryogenic levels to high heat provides a reliable solution where most other polymers would fail.

- If your primary focus is electrical insulation: Its high dielectric strength is critical for manufacturing high-frequency cables and insulating sensitive electronic components.

Ultimately, understanding these distinct properties allows you to leverage Teflon not just as a material, but as a strategic solution to complex engineering challenges.

Summary Table:

| Key Property | Practical Impact |

|---|---|

| Extreme Chemical Inertness | Resists almost all chemicals, ideal for seals and linings in corrosive environments. |

| Exceptionally Low Friction | Provides non-stick surfaces and reduces wear in bearings and mechanical parts. |

| Broad Thermal Stability | Performs reliably from -200°C to 260°C, suitable for extreme temperature applications. |

| Superior Electrical Insulation | Excellent dielectric strength for high-performance wiring and electronics. |

Need high-performance PTFE components that leverage these unique properties?

KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your components meet the highest standards for chemical resistance, thermal stability, and performance.

Contact KINTEK today to discuss your project requirements and discover how our custom PTFE solutions can solve your complex engineering challenges.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What fillers are used to enhance PTFE properties? Tailor PTFE for Superior Wear and Strength

- What are the key properties of PTFE that make it ideal for industrial use? Unlock Unmatched Performance in Harsh Environments

- Can PTFE be modified with additives? Enhance Performance for Demanding Applications

- What are the limitations of PTFE in its applications? Understanding Its Mechanical Weaknesses

- What is PTFE commonly known as? Discover the High-Performance Material Behind Teflon

- What are the key properties of PTFE that make it suitable for high-performance applications? Unlock Extreme Performance

- What properties make Teflon ideal for medical applications? Discover Its Critical Role in Safety & Performance

- How do the low friction properties of PTFE benefit pharmaceutical manufacturing setups? Boost Efficiency & Cut Costs