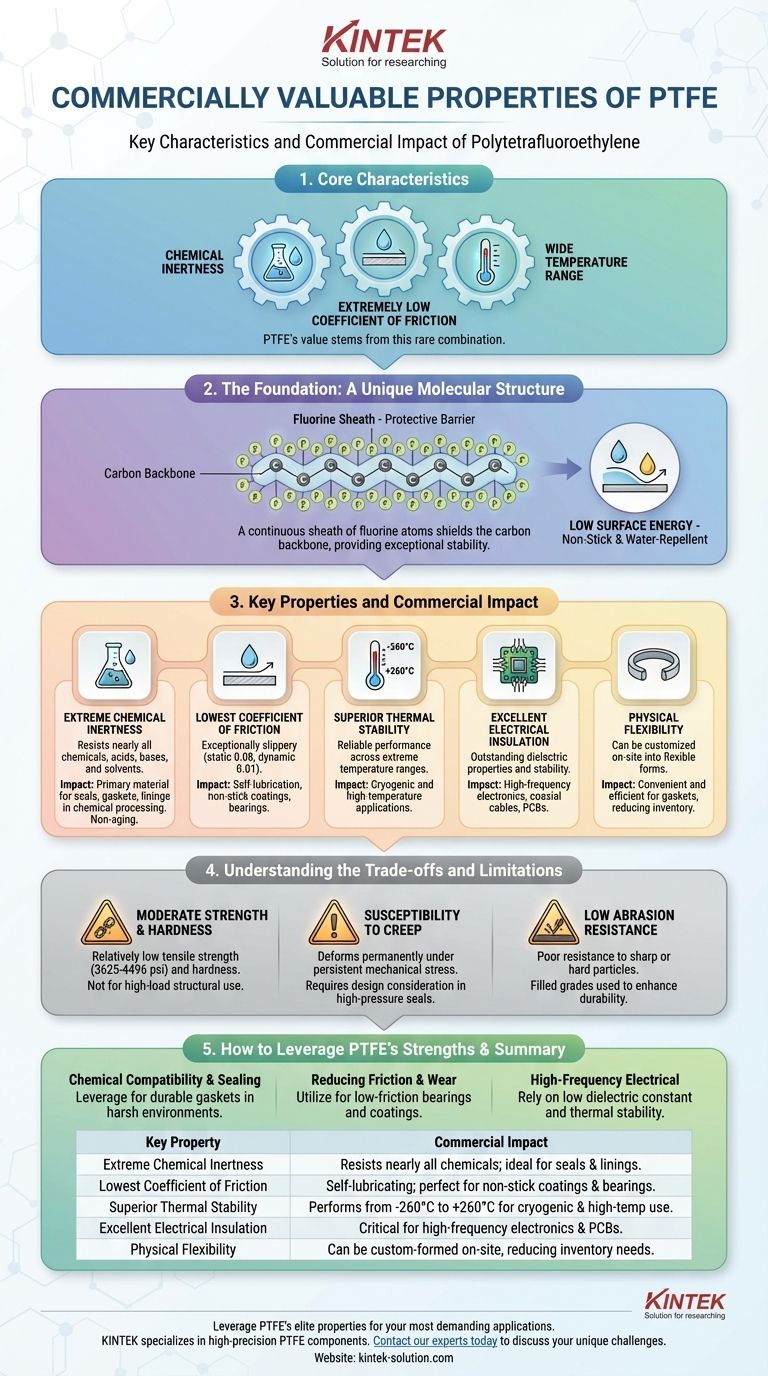

The commercial value of Polytetrafluoroethylene (PTFE) is rooted in a rare combination of three core characteristics: it is almost completely chemically inert, it possesses an extremely low coefficient of friction, and it maintains these properties across a wide range of temperatures. This makes it an irreplaceable material for applications where resistance to harsh environments, non-stick surfaces, or self-lubrication is critical.

At its core, PTFE's value comes from its unique molecular structure. A protective sheath of fluorine atoms shields its carbon backbone, making the material exceptionally stable and unreactive, which in turn gives rise to its famous non-stick and chemical-resistant properties.

The Foundation: A Unique Molecular Structure

To understand why PTFE is so valuable, we must first look at its atomic-level design. Its properties are not accidental; they are a direct result of its chemistry.

The Fluorine Sheath

PTFE's structure consists of a long chain of carbon atoms, but each carbon is bonded to two fluorine atoms. These fluorine atoms are large and form a tight, continuous sheath around the carbon backbone.

This sheath acts as a protective barrier, preventing other chemicals from reaching and reacting with the vulnerable carbon-carbon bonds. This is the fundamental reason for PTFE's exceptional chemical resistance and thermal stability.

Low Surface Energy

The fluorine sheath also creates a molecule with very low surface energy. This means there are very weak forces of attraction between PTFE and other substances.

This low surface energy is what gives PTFE its famous non-stick, anti-adhesion, and water-repellent properties. Materials simply do not want to stick to it.

Key Properties and Their Commercial Impact

The unique molecular structure translates directly into a set of commercially valuable performance characteristics that are difficult to achieve with other polymers.

Extreme Chemical Inertness

Because of the fluorine sheath, PTFE is resistant to nearly all chemicals, including aggressive acids, bases, and solvents. This makes it a primary material for seals, gaskets, and linings in the chemical processing industry.

It is also non-aging and resistant to UV light and weathering, ensuring long-term stability in exposed applications.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, with a static value of 0.08 and a dynamic value as low as 0.01. This makes it exceptionally slippery.

This property is leveraged in applications requiring self-lubrication, such as bearings and non-stick coatings on cookware and industrial equipment.

Superior Thermal Stability

PTFE performs reliably across an extremely broad temperature range, typically from -260°C to +260°C. This allows it to be used in cryogenic applications as well as high-temperature environments where other plastics would fail.

Excellent Electrical Insulation

The stable, non-polar nature of the PTFE molecule makes it an outstanding electrical insulator. It has a low dielectric constant and maintains its insulating properties even in hot and wet conditions.

This makes it critical for high-frequency electronics, such as in coaxial cables and printed circuit boards (PCBs).

Physical Flexibility and Adaptability

Despite its robustness, PTFE can be made into flexible forms. In sealing applications, this allows materials like PTFE spacers to be customized on-site into gaskets of any size.

This adaptability eliminates the need for large inventories of pre-manufactured parts, making operations more convenient and efficient.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE's core properties are exceptional, it is important to understand its mechanical limitations to use it effectively.

Moderate Tensile Strength and Hardness

Compared to many engineering plastics, PTFE has a relatively low tensile strength (3625-4496 psi) and hardness (60-65 Shore D). It is a mechanically soft material.

This means it is not suitable for high-load structural applications where rigidity and high strength are the primary requirements.

Susceptibility to Creep

PTFE is susceptible to "creep," which is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

While it has some creep resistance, in high-pressure sealing applications, this must be accounted for in the design to prevent the seal from slowly deforming and failing over time.

Low Abrasion Resistance

The same low-friction surface that makes PTFE so valuable also means it has relatively poor resistance to abrasion and wear from sharp or hard particles. In such applications, filled grades of PTFE are often used to enhance durability.

How to Leverage PTFE's Strengths

Choosing PTFE is about matching its unique profile to a specific problem. Your decision should be based on which of its elite properties you need most.

- If your primary focus is chemical compatibility and sealing: Leverage its near-total chemical inertness and flexibility for creating durable gaskets and O-rings in harsh chemical or high-temperature environments.

- If your primary focus is reducing friction and wear: Utilize its self-lubricating, non-stick surface for low-friction bearings, coatings, or any application where smooth movement is essential without external lubricants.

- If your primary focus is high-frequency electrical applications: Rely on its low dielectric constant and excellent thermal stability for insulating critical components in demanding electronics.

Ultimately, PTFE is a powerful problem-solving material whose unique molecular structure makes it the definitive choice for some of engineering's toughest challenges.

Summary Table:

| Key Property | Commercial Impact |

|---|---|

| Extreme Chemical Inertness | Resists nearly all chemicals; ideal for seals & linings. |

| Lowest Coefficient of Friction | Self-lubricating; perfect for non-stick coatings & bearings. |

| Superior Thermal Stability | Performs from -260°C to +260°C for cryogenic & high-temp use. |

| Excellent Electrical Insulation | Critical for high-frequency electronics & PCBs. |

| Physical Flexibility | Can be custom-formed on-site, reducing inventory needs. |

Leverage PTFE's elite properties for your most demanding applications. At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our custom fabrication ensures optimal performance. Contact our experts today to discuss how our PTFE solutions can solve your unique challenges.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity