Standard PTFE gaskets are defined by their exceptional chemical resistance, a remarkably wide operational temperature range, and an inherently non-stick, low-friction surface. These core properties, combined with their durability and purity, make them a foundational material for sealing in demanding industrial environments.

The true value of a standard PTFE gasket is not just its individual properties, but its unique combination of near-universal chemical inertness and extreme temperature stability. However, understanding its mechanical limitations—specifically its rigidity and potential for creep—is critical to using it effectively.

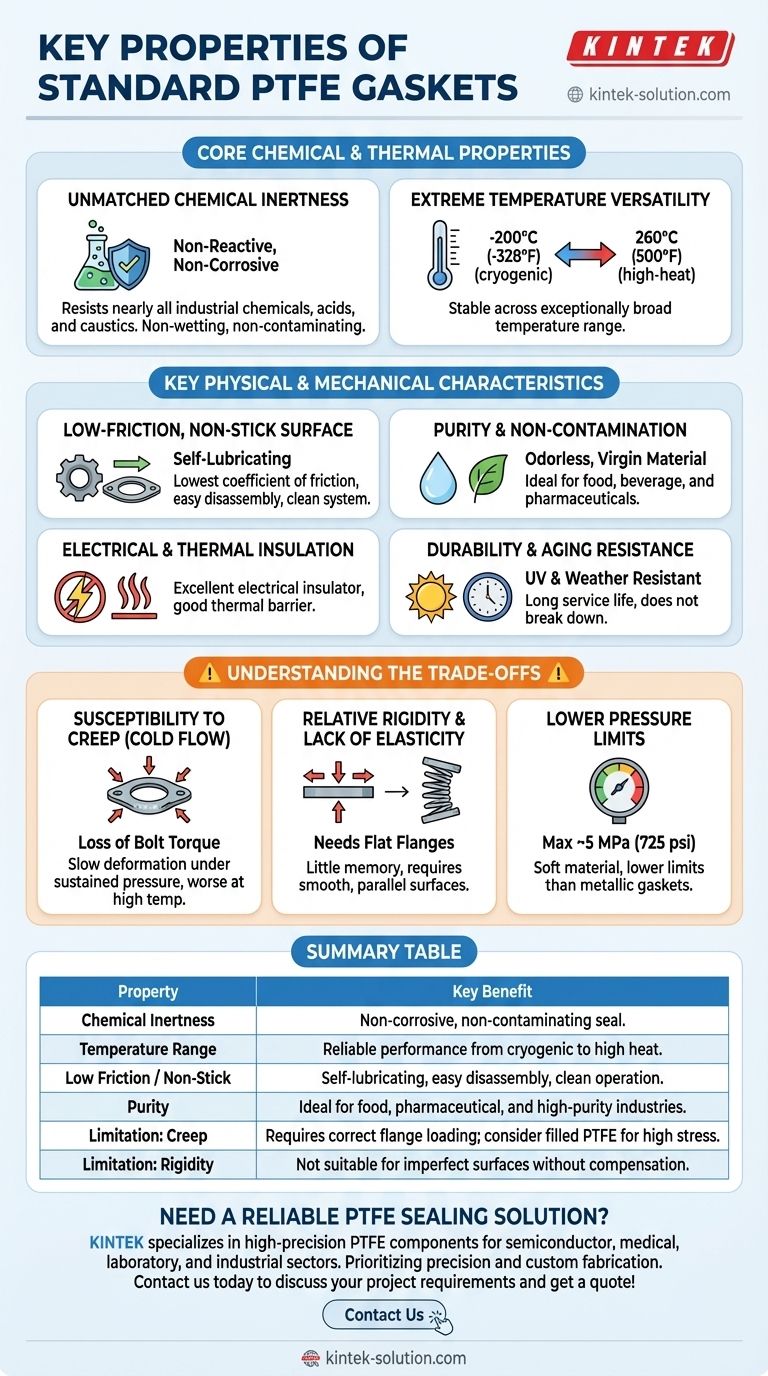

The Core Chemical and Thermal Properties

To understand if PTFE is the right choice, we must first look at its two most dominant characteristics: its relationship with chemicals and temperature.

Unmatched Chemical Inertness

Standard PTFE (polytetrafluoroethylene) is famously non-reactive. It can handle the vast majority of industrial chemicals, acids, and caustics without degrading.

This property makes it non-corrosive, non-wetting, and non-contaminating. The gasket will not leach materials into the process media, a critical feature for sensitive applications.

Extreme Temperature Versatility

PTFE gaskets perform reliably across an exceptionally broad temperature spectrum, from cryogenic lows of -200°C (-328°F) up to high-heat applications of 260°C (500°F).

This stability ensures the gasket maintains its integrity and sealing capability without becoming brittle at low temperatures or degrading at high temperatures.

Key Physical and Mechanical Characteristics

Beyond its core resistances, the physical nature of PTFE directly impacts its performance as a sealant.

Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property is ideal for applications where components might move or rotate.

Its non-stick surface prevents media from adhering to the gasket, ensuring a clean system and making disassembly of flanged joints much easier.

Purity and Non-Contamination

Virgin PTFE is an inherently pure material. It is odorless and will not contaminate the sealing surfaces or the process media.

This makes it a default choice for hygienic industries such as food, beverage, and pharmaceuticals, where preventing contamination is a primary concern.

Electrical and Thermal Insulation

PTFE is an excellent electrical insulator and is non-conductive. It also provides good thermal insulation, helping to reduce heat transfer between sealed components.

Durability and Aging Resistance

Standard PTFE is highly resistant to aging and degradation from environmental factors. It does not break down when exposed to UV light or weather, contributing to a long service life.

Understanding the Trade-offs of Standard PTFE

No material is perfect for every situation. Acknowledging the limitations of standard PTFE is crucial for preventing seal failure.

Susceptibility to Creep (Cold Flow)

The most significant limitation of standard PTFE is its tendency to "creep" or "cold flow." Under sustained pressure from a bolted flange, the material can slowly deform and flow out of the seal area, leading to a loss of bolt torque and potential leaks.

This effect is more pronounced at higher temperatures and is the primary reason why modified or filled PTFE grades were developed.

Relative Rigidity and Lack of Elasticity

Compared to rubber or elastomeric gaskets, standard PTFE is quite rigid and has very little "memory." It does not spring back well after being compressed.

This means it requires smooth, flat, and parallel flange surfaces to create an effective seal. It cannot easily compensate for surface imperfections or misalignment.

Lower Pressure Limits

While durable, standard PTFE is a relatively soft material with lower pressure limits than metallic or semi-metallic gaskets. Some specifications cite a maximum pressure of around 5 MPa (725 psi), though this is highly dependent on temperature and flange design.

Making the Right Choice for Your Application

Selecting the right gasket depends entirely on your application's primary demands.

- If your primary focus is chemical compatibility: Standard PTFE is an excellent first choice, as it resists nearly all industrial chemicals.

- If your application involves a wide temperature range: Its stability from cryogenic levels to 260°C makes it a highly reliable option.

- If you require a pure, non-contaminating seal: PTFE is the ideal material for food, pharmaceutical, and high-purity applications.

- If you are dealing with high pressures or imperfect flanges: You should investigate filled or expanded PTFE grades, as standard PTFE's potential for creep may lead to seal failure.

Understanding both its exceptional inertness and its mechanical constraints is the key to leveraging PTFE for a reliable, long-lasting seal.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and caustics. | Non-corrosive, non-contaminating seal. |

| Temperature Range | Stable from -200°C (-328°F) to 260°C (500°F). | Reliable performance from cryogenic to high heat. |

| Low Friction / Non-Stick | One of the lowest coefficients of friction. | Self-lubricating, easy disassembly, clean operation. |

| Purity | Inherently pure, odorless virgin material. | Ideal for food, pharmaceutical, and high-purity industries. |

| Limitation: Creep | Can deform under sustained pressure (cold flow). | Requires correct flange loading; consider filled PTFE for high stress. |

| Limitation: Rigidity | Little elasticity, requires flat, parallel flanges. | Not suitable for imperfect surfaces without compensation. |

Need a Reliable PTFE Sealing Solution?

Leverage the exceptional properties of PTFE for your most demanding applications. KINTEK specializes in manufacturing high-precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact seal you need for optimal performance and longevity.

Contact us today to discuss your project requirements and get a quote! #ContactForm

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key performance capabilities of spring energized PTFE seals? Conquer Extreme Environments

- What are the limitations of PTFE when used as a mechanical component? Overcoming Softness & Instability

- What are the key benefits of using PTFE for piston rings in oil-free compressors? Achieve Clean, Efficient Compression

- What is unique about PTFE waffle seals and their applications? Superior Sealing with Built-In Contamination Control

- What are the benefits of PTFE with Carbon-Graphite? Achieve Superior Wear Resistance and Low Friction

- What are the primary uses of Teflon encapsulated O-Rings? Seal Against Aggressive Chemicals & High Temperatures

- What are the temperature ranges for PTFE and graphite packing? A Guide to Selecting the Right Seal

- Why are spring-energized PTFE seals suitable for the aerospace industry? Unmatched Reliability in Extreme Conditions