Adding carbon-graphite fillers to PTFE transforms it into a high-performance engineering material for demanding dynamic applications. This blend combines PTFE's inherent chemical inertness and low friction with the strength, wear resistance, and thermal conductivity of carbon and graphite. The result is a superior material for components like seals, bearings, and wear rings that must endure high speeds and friction.

The fundamental benefit of carbon-graphite filled PTFE is achieving exceptional wear resistance and thermal stability without sacrificing the low friction and chemical resistance inherent to the base material. This makes it a superior choice for dynamic sealing and bearing applications where other materials would fail prematurely.

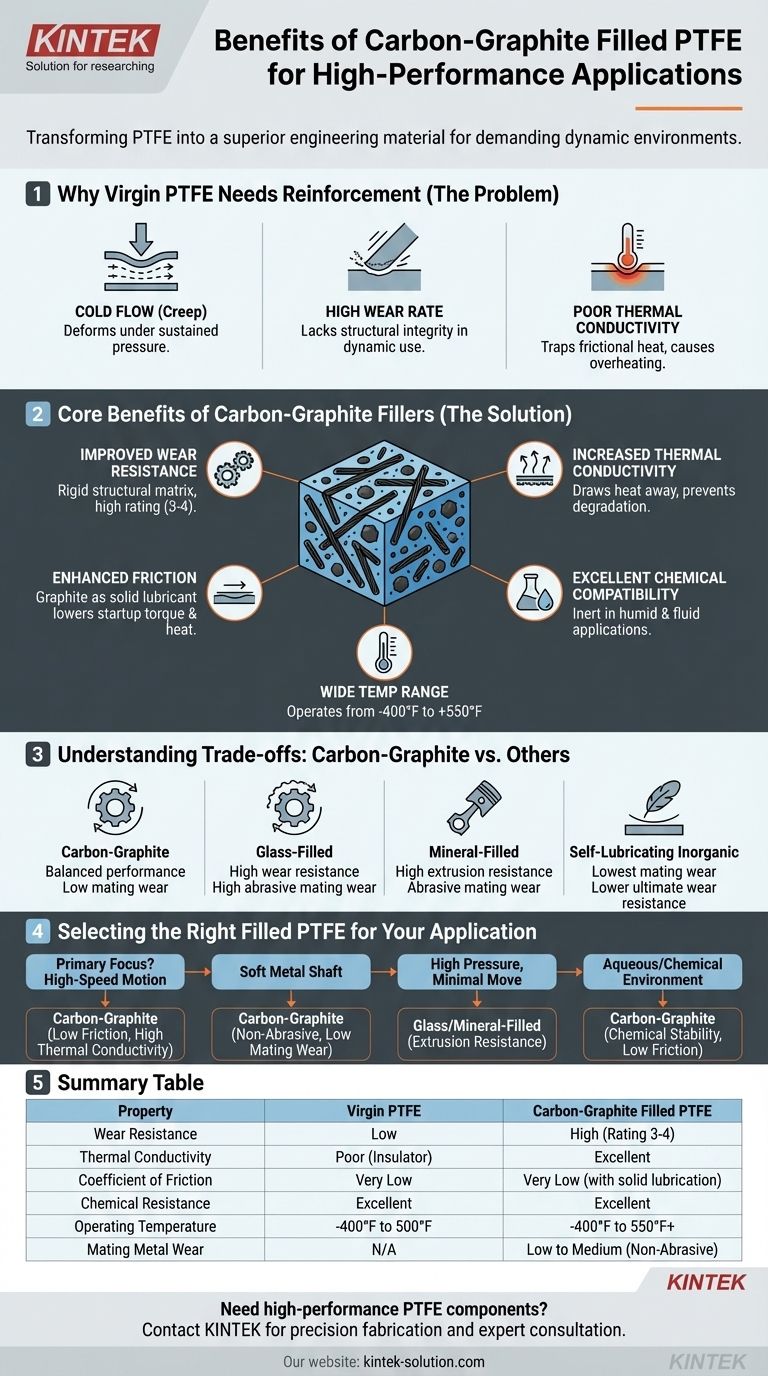

Why Virgin PTFE Needs Reinforcement

While Polytetrafluoroethylene (PTFE) is famous for its non-stick properties and chemical resistance, its pure form has significant mechanical limitations.

The Problem of "Cold Flow"

Unfilled PTFE is mechanically soft and susceptible to "cold flow," or creep. Under sustained pressure, it will slowly deform, which is unacceptable for components that must hold a precise shape, like seals.

High Wear Rate

In dynamic applications involving friction and movement, virgin PTFE wears down very quickly. It lacks the structural integrity to withstand abrasive forces over time.

Poor Thermal Conductivity

Friction generates heat. Pure PTFE is an excellent thermal insulator, meaning it traps this heat at the contact surface, which can lead to overheating and accelerated failure of the component.

Core Benefits of Carbon-Graphite Fillers

Adding a precise blend of carbon and graphite systematically addresses the weaknesses of virgin PTFE, creating a robust composite material.

Dramatically Improved Wear Resistance

Carbon fibers provide a rigid structural matrix within the PTFE, drastically increasing its resistance to wear. Materials with this filler often achieve a high wear resistance rating of 3 or 4, signifying excellent durability.

Enhanced Frictional Characteristics

Graphite acts as a solid lubricant within the material matrix. This lowers the coefficient of friction, reducing both startup torque and heat generation during high-speed rotary or reciprocating motion.

Increased Thermal Conductivity

Carbon is an effective thermal conductor. It draws frictional heat away from the contact surface and dissipates it through the component, preventing thermal degradation and extending service life.

Excellent Chemical Compatibility

Carbon and graphite are highly inert materials. Their addition does not compromise PTFE's outstanding resistance to chemicals, making these blends ideal for use in humid conditions and fluid applications.

Wide Operating Temperature Range

Carbon-graphite blends maintain their integrity across an exceptionally broad temperature spectrum, with typical service ranges from -400°F to over 550°F.

Understanding the Trade-offs: Carbon-Graphite vs. Other Fillers

While carbon-graphite is a powerful all-around filler, the optimal choice depends on balancing performance properties, especially how the material interacts with its mating surface.

vs. Glass-Filled PTFE

Glass fillers also provide excellent wear resistance but are highly abrasive. This can cause significant wear on softer mating shafts, a characteristic noted as "high mating metal wear." Carbon-graphite is far less abrasive, making it the superior choice for protecting softer metal surfaces.

vs. Mineral-Filled PTFE

Mineral fillers can offer greater extrusion resistance, making them suitable for high-pressure static seals. However, like glass, they can be abrasive to mating components.

vs. Self-Lubricating Inorganic Fillers

Some proprietary inorganic fillers are specifically designed to be extremely gentle on mating surfaces, offering one of the lowest metal-mating wear characteristics available. The trade-off may be in ultimate wear resistance or cost compared to a standard carbon-graphite blend. Carbon-graphite offers a more balanced profile of high self-wear resistance and low mating surface wear.

Selecting the Right Filled PTFE for Your Application

Your choice of filler depends entirely on the specific demands of your operating environment.

- If your primary focus is high-speed rotary or reciprocating motion: Carbon-graphite filled PTFE is often the best choice due to its low friction, high thermal conductivity, and excellent wear life.

- If your primary focus is sealing against a soft metal shaft (e.g., aluminum): Carbon-graphite is crucial for preventing abrasion, exhibiting low to medium mating metal wear.

- If your primary focus is high pressure with minimal movement: A glass or mineral-filled PTFE may offer superior extrusion resistance, provided shaft wear is not a concern.

- If your primary focus is service in aqueous or chemical environments: Carbon-graphite provides exceptional performance, maintaining stability and low friction in fluid applications.

By matching the unique properties of the filler to your application's specific challenges, you ensure optimal performance and longevity for your components.

Summary Table:

| Property | Virgin PTFE | Carbon-Graphite Filled PTFE |

|---|---|---|

| Wear Resistance | Low | High (Rating 3-4) |

| Thermal Conductivity | Poor (Insulator) | Excellent |

| Coefficient of Friction | Very Low | Very Low (with solid lubrication) |

| Chemical Resistance | Excellent | Excellent |

| Operating Temperature | -400°F to 500°F | -400°F to 550°F+ |

| Mating Metal Wear | N/A | Low to Medium (Non-Abrasive) |

Need high-performance PTFE components that won't fail under pressure?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, bearings, and liners—enhanced with premium fillers like carbon-graphite for superior performance. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom fabrication services ensure your components meet exact specifications, from prototypes to high-volume orders.

Let us help you solve your most challenging application problems. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts