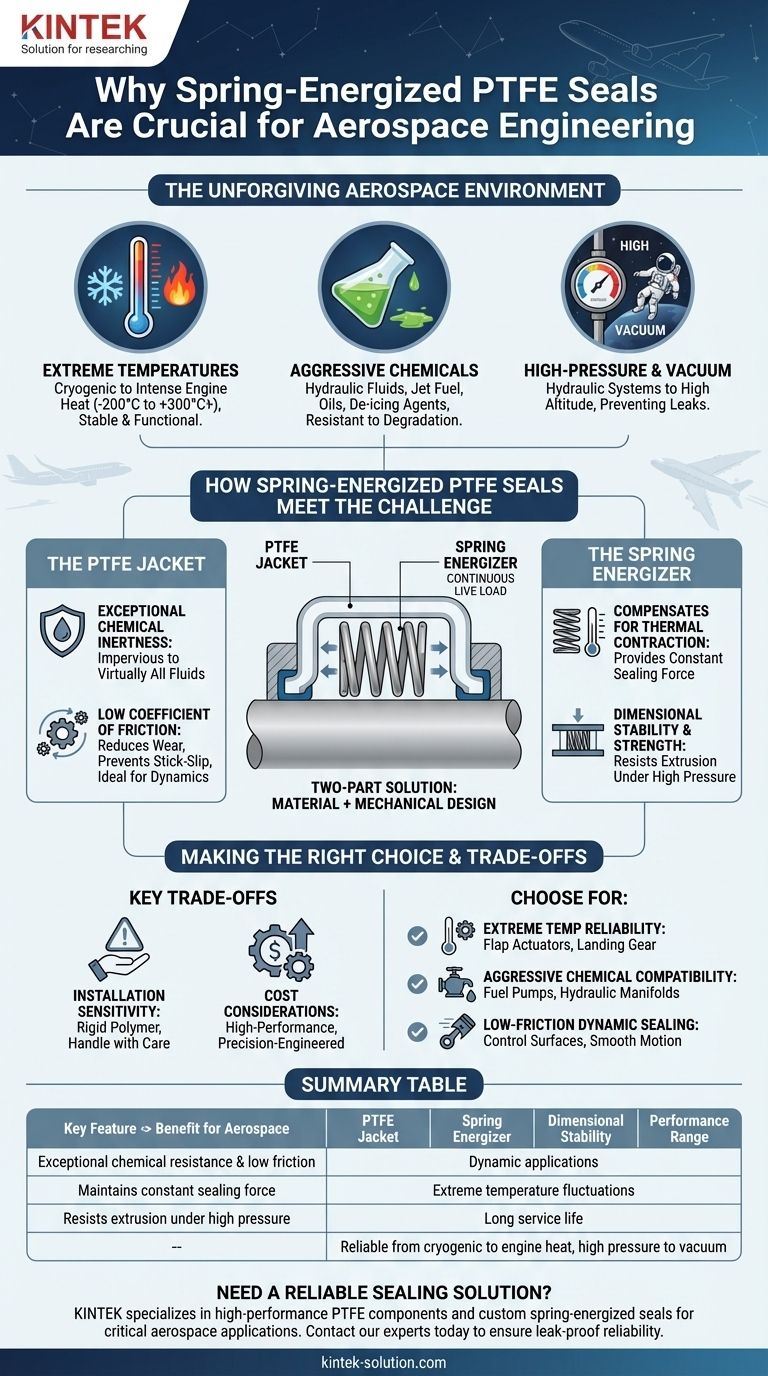

Spring-energized PTFE seals are a cornerstone of aerospace engineering because they deliver unparalleled reliability in environments defined by extremes. Their suitability stems from a unique combination of material properties and mechanical design, ensuring consistent performance from cryogenic temperatures to the intense heat of an engine, and from ground-level pressure to the vacuum of high altitude.

The core reason for their use is that aerospace applications demand a seal that provides a constant, reliable sealing force despite massive fluctuations in temperature, pressure, and chemical exposure. The spring energizer compensates for the PTFE jacket's thermal expansion and contraction, ensuring a leak-proof barrier where failure is not an option.

The Unforgiving Aerospace Sealing Environment

To understand the value of these seals, we must first appreciate the challenges they are designed to overcome. Aerospace components operate in some of the most hostile conditions imaginable.

Extreme Temperature Fluctuations

Components are exposed to a vast thermal range, from the cryogenic cold of liquid fuels and high-altitude air to the intense friction-generated and engine-radiated heat. Materials must remain stable and functional across this entire spectrum.

Aggressive Chemical Exposure

Aerospace systems rely on a variety of aggressive fluids. Seals must withstand constant contact with hydraulic fluids, jet fuel, lubricating oils, and de-icing agents without degrading, swelling, or failing.

High-Pressure and Vacuum Conditions

Seals must perform flawlessly under the high pressures of hydraulic actuator systems and landing gear while also preventing leaks in the near-vacuum conditions experienced at high altitudes.

How Spring-Energized PTFE Seals Meet the Challenge

This seal design is a two-part solution, where each component addresses specific environmental challenges. The PTFE jacket provides the robust material interface, while the internal spring provides the consistent mechanical force.

The Role of the PTFE Jacket

The outer seal, or jacket, is made from Polytetrafluoroethylene (PTFE). This material provides the primary defense with its exceptional chemical inertness, making it impervious to virtually all aerospace fluids.

Furthermore, PTFE has an extremely low coefficient of friction. This quality is critical in dynamic applications like actuators, as it reduces wear and tear, prevents stick-slip motion, and minimizes the risk of debris buildup that could compromise a system.

The Function of the Spring Energizer

PTFE has poor "memory" and is subject to thermal contraction in cold temperatures. The internal metallic spring is the "energizer" that solves this problem by providing a continuous, live load against the sealing surfaces.

This spring ensures that even as the PTFE jacket expands with heat or contracts with cold, a constant sealing force is maintained. This mechanical resilience is what guarantees seal integrity across wide temperature and pressure ranges.

Dimensional Stability and Strength

The combination of a robust PTFE jacket and a high-strength spring results in excellent dimensional stability. The seal resists extrusion under high pressure and maintains its designed shape, ensuring a long and reliable service life in high-stress components like rotorheads and landing gear.

Understanding the Trade-offs

While highly effective, these seals are a specialized engineering component, and their selection involves understanding key trade-offs.

Installation Sensitivity

The PTFE jacket is a relatively rigid polymer. Unlike a softer elastomeric o-ring, it can be damaged during installation if not handled with care. Scratches or gouges on the sealing lip can create a leak path, compromising the seal's function.

Cost Considerations

These are high-performance, precision-engineered components. Their manufacturing cost is significantly higher than that of standard elastomeric seals, making them best suited for critical applications where performance justifies the investment.

Making the Right Choice for Your System

The decision to use a spring-energized PTFE seal should be driven by the operational demands of the specific application.

- If your primary focus is reliability in extreme temperature cycles: These seals are the superior choice for components like flap actuators, external gearboxes, and landing gear systems.

- If your primary focus is compatibility with aggressive chemicals: They are ideal for fuel pumps, hydraulic manifolds, and engine lubrication systems where fluid exposure would degrade other materials.

- If your primary focus is low-friction dynamic sealing: Their properties make them perfect for control surface actuators and other systems requiring smooth, repeatable motion with minimal wear.

Ultimately, spring-energized PTFE seals provide the uncompromising performance and reliability required for flight-critical systems where failure is simply not an option.

Summary Table:

| Key Feature | Benefit for Aerospace |

|---|---|

| PTFE Jacket | Exceptional chemical resistance and low friction for dynamic applications. |

| Spring Energizer | Maintains constant sealing force across extreme temperature fluctuations. |

| Dimensional Stability | Resists extrusion under high pressure, ensuring long service life. |

| Performance Range | Reliable from cryogenic cold to engine heat, and high pressure to vacuum. |

Need a reliable sealing solution for your critical aerospace application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom spring-energized seals. Our expertise ensures your systems are protected against extreme temperatures, aggressive chemicals, and high-pressure environments.

We partner with leading companies in the semiconductor, medical, laboratory, and industrial sectors, delivering quality from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and ensure leak-proof reliability where failure is not an option.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation