Spring energized PTFE seals deliver exceptional performance in environments where traditional elastomeric seals consistently fail. They achieve this through a unique design that leverages the standout properties of Polytetrafluoroethylene (PTFE) and a metallic spring energizer. Key capabilities include operation across an extremely wide temperature range, near-universal chemical compatibility, and reliable sealing under high pressures and high speeds, all while exhibiting very low friction.

The core of this technology is its two-part system: a precision-machined PTFE jacket provides the elite chemical and thermal resistance, while an internal spring delivers the constant, reliable force necessary to maintain a leak-tight seal in the most demanding conditions.

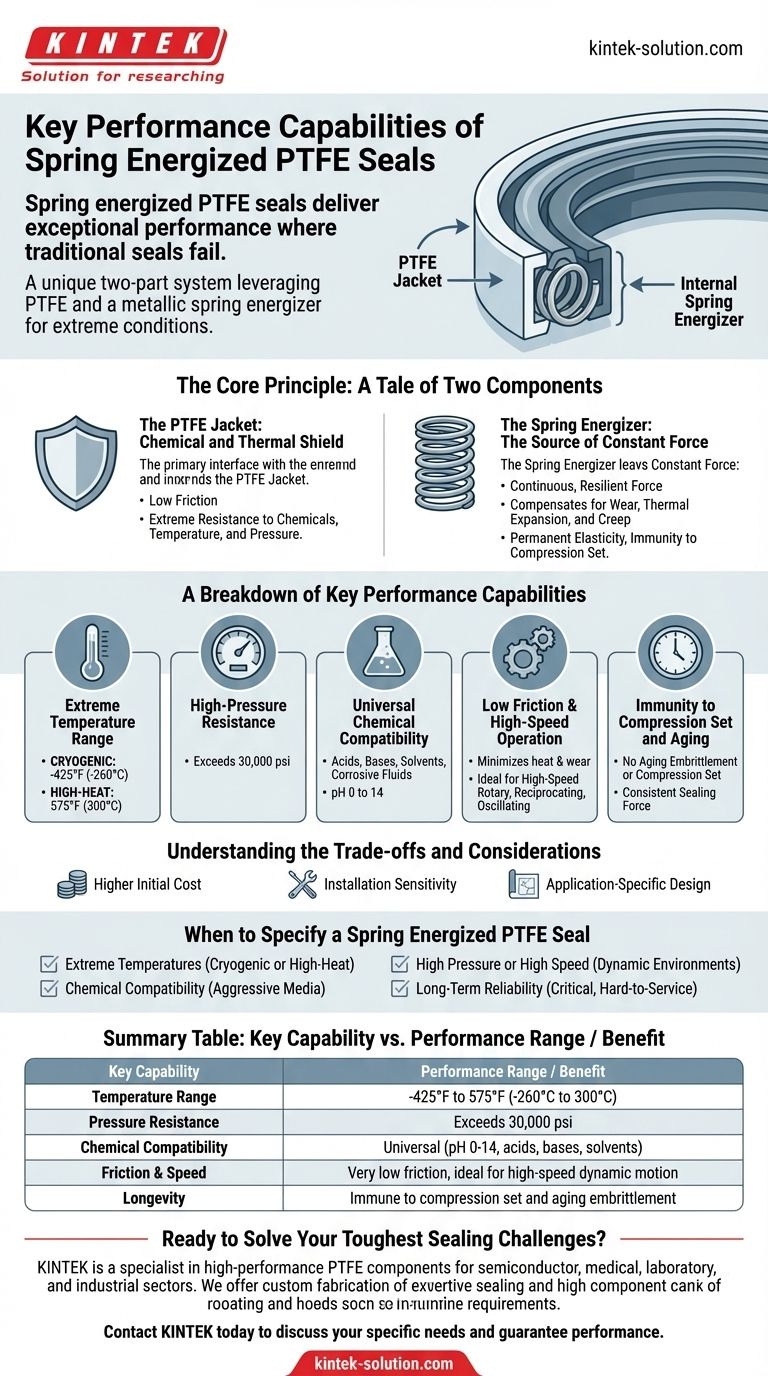

The Core Principle: A Tale of Two Components

Understanding why these seals are so effective requires looking at how their two main components work together. They solve the inherent limitations of using either a polymer or a metal spring alone.

The PTFE Jacket: The Chemical and Thermal Shield

The outer seal jacket is made from PTFE, a material often called the "King of Plastics" for good reason. It provides the primary interface with the operating environment.

Its key characteristics are low friction, which reduces wear and energy loss, and extreme resistance to chemicals, temperature, and pressure.

The Spring Energizer: The Source of Constant Force

Unlike rubber, PTFE is not naturally elastic and is susceptible to cold flow. The internal metallic spring is the engine of the seal, providing continuous, resilient force against the sealing surfaces.

This spring compensates for seal wear, thermal expansion or contraction, and any material creep. This is what gives the seal its "permanent elasticity" and immunity to the compression set that plagues traditional seals.

A Breakdown of Key Performance Capabilities

The synergy between the PTFE jacket and the spring energizer results in a sealing solution with a performance envelope that far exceeds conventional options.

Extreme Temperature Range

These seals function reliably in conditions that would cause other materials to become brittle or degrade. They are rated for both cryogenic service down to -425°F (-260°C) and high-temperature service up to 575°F (300°C).

High-Pressure Resistance

The spring ensures the seal lip remains firmly engaged even under extreme force. Spring energized PTFE seals are frequently specified for high-pressure applications exceeding 30,000 psi.

Universal Chemical Compatibility

PTFE is virtually inert, making it compatible with almost any industrial fluid. These seals are ideal for aggressive media, including acids, bases, solvents, and corrosive fluids across a pH range of 0 to 14.

Low Friction and High-Speed Operation

The low coefficient of friction inherent to PTFE minimizes heat generation and wear. This makes the seals exceptionally well-suited for high-speed rotary, reciprocating, and oscillating applications where other seals would quickly overheat and fail.

Immunity to Compression Set and Aging

Elastomeric seals can harden, crack, or lose their shape over time, leading to leaks. The metallic spring does not suffer from aging embrittlement or compression set, ensuring a consistent sealing force over a very long operational life.

Understanding the Trade-offs and Considerations

While their capabilities are significant, these seals are a specialized component. Objectively assessing their fit requires understanding their trade-offs.

Higher Initial Cost

These are premium, precision-engineered solutions. The advanced materials and manufacturing process mean they have a higher unit cost compared to standard O-rings or hydraulic seals. Their longevity, however, can often justify the investment by reducing downtime and maintenance.

Installation Sensitivity

The PTFE jacket, while durable in operation, can be damaged during installation if proper care is not taken. Scratches or nicks on the sealing surface can create a leak path, so careful handling and correct tools are essential.

Application-Specific Design

This is not a one-size-fits-all product. Peak performance depends on correctly matching the PTFE blend, spring material, and spring geometry to the specific application's pressure, temperature, speed, and media. This requires a more detailed engineering assessment than a general-purpose seal.

When to Specify a Spring Energized PTFE Seal

Use this guide to determine if this technology is the correct solution for your challenge.

- If your primary focus is extreme temperatures: These seals are a definitive choice for both cryogenic and high-heat applications where elastomers would immediately fail.

- If your primary focus is chemical compatibility: Specify these seals when dealing with aggressive chemicals, solvents, or a wide range of media that would degrade other materials.

- If your primary focus is high pressure or high speed: The spring-energized design ensures seal integrity in dynamic, high-stress environments that would overwhelm conventional seals.

- If your primary focus is long-term reliability: Use these seals in critical, hard-to-service applications where seal failure is not an option and immunity to aging is paramount.

By combining an advanced polymer jacket with a resilient metal spring, these seals solve the most difficult sealing challenges across virtually every industry.

Summary Table:

| Key Capability | Performance Range / Benefit |

|---|---|

| Temperature Range | -425°F to 575°F (-260°C to 300°C) |

| Pressure Resistance | Exceeds 30,000 psi |

| Chemical Compatibility | Universal (pH 0-14, acids, bases, solvents) |

| Friction & Speed | Very low friction, ideal for high-speed dynamic motion |

| Longevity | Immune to compression set and aging embrittlement |

Ready to Solve Your Toughest Sealing Challenges?

At KINTEK, we specialize in manufacturing high-performance, precision PTFE components, including custom spring energized seals. Our expertise ensures your critical applications in the semiconductor, medical, laboratory, and industrial sectors achieve maximum reliability and longevity.

We offer custom fabrication from prototypes to high-volume orders, tailored to your exact pressure, temperature, and chemical requirements.

Contact KINTEK today to discuss your specific needs and let our sealing experts provide a solution that guarantees performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components