The key properties of Polytetrafluoroethylene (PTFE) that make it a premier sealing material are its extreme temperature resistance, near-universal chemical inertness, and exceptionally low coefficient of friction. This unique combination allows PTFE seals to perform reliably in demanding chemical and thermal environments where most other materials would degrade and fail.

The true value of PTFE in sealing technology isn't just one standout feature, but the powerful synergy of its properties. It solves challenges related to extreme temperatures, aggressive chemicals, and dynamic friction simultaneously, making it a uniquely versatile problem-solver for complex engineering applications.

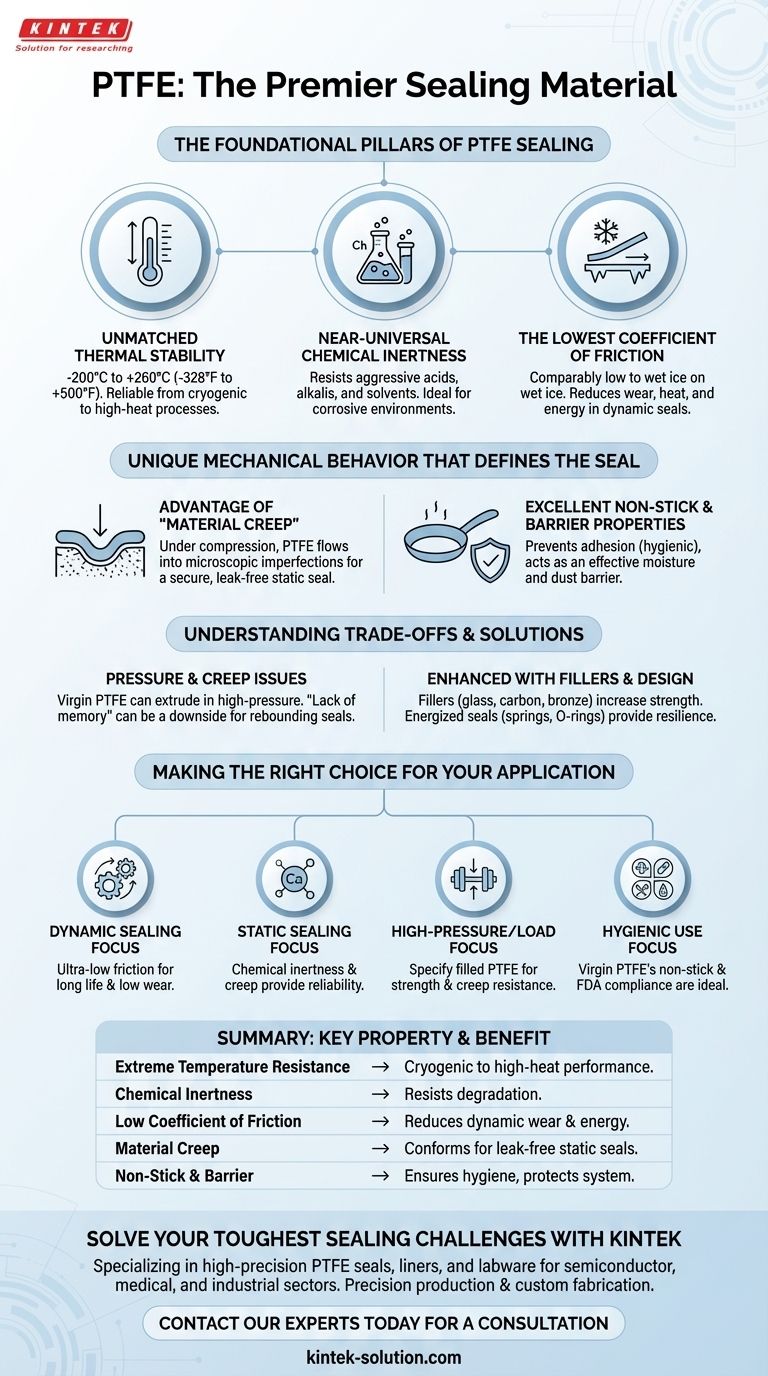

The Foundational Pillars of PTFE Sealing

To understand why PTFE is so effective, we must look at its core chemical and thermal characteristics. These foundational properties are what enable its superior performance.

Unmatched Thermal Stability

PTFE operates reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to be used in everything from cryogenic applications to high-heat industrial processes without losing its structural integrity or sealing capability.

Near-Universal Chemical Inertness

PTFE is famous for being chemically inert, meaning it resists degradation from nearly all industrial chemicals, including aggressive acids, alkalis, and organic solvents.

This makes it the material of choice for sealing systems that handle corrosive fluids or gases. The only common exceptions are molten alkali metals and certain potent halogenated compounds.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material, often compared to wet ice on wet ice.

For dynamic seals (where parts move against each other), this high gliding ability means significantly less wear, lower heat generation, and reduced operational energy consumption over the seal's long life.

The Unique Mechanical Behavior That Defines the Seal

Beyond its foundational properties, PTFE's mechanical behavior is what allows it to form and maintain a secure seal under real-world conditions.

The Advantage of "Material Creep"

Unlike elastomers, PTFE lacks elastic "memory." Under compression, it exhibits a behavior known as creep, or cold flow.

While this can be a drawback in some applications, it is a critical advantage for static seals. Creep allows the PTFE material to flow into and conform to microscopic imperfections on mating surfaces, creating an exceptionally secure and leak-free seal.

Excellent Non-Stick and Barrier Properties

PTFE's non-stick surface prevents materials from adhering to the seal. This is crucial in food, medical, and pharmaceutical applications for maintaining hygiene and preventing contamination.

Furthermore, it acts as an effective barrier against moisture and dust, protecting the integrity of the system it is sealing.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging PTFE's limitations is key to using it correctly and effectively.

Pressure and Mechanical Strength

Virgin (unfilled) PTFE is a relatively soft material. In high-pressure applications, it can be prone to extrusion or excessive creep, potentially compromising the seal.

The Role of Fillers

To overcome its mechanical limitations, PTFE is often blended with fillers. Adding materials like glass fiber, carbon, bronze, or graphite significantly enhances its compressive strength, wear resistance, and resistance to creep, making it suitable for high-pressure and high-load scenarios.

The "Lack of Memory" Downside

The same creep that is beneficial for static face seals can be a limitation for applications that require a seal to rebound after pressure is removed. In these cases, energized seals that incorporate a spring or O-ring are often used to provide the necessary resilience.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is dynamic sealing (moving parts): The ultra-low friction of PTFE is your greatest asset, ensuring long life and low wear.

- If your primary focus is static sealing in aggressive environments: PTFE's chemical inertness and its ability to creep and conform to surfaces will provide the most reliable seal.

- If your primary focus is high-pressure or high-load applications: You must specify a filled PTFE grade to gain the necessary mechanical strength and creep resistance.

- If your primary focus is hygienic use (food or medical): Virgin PTFE's non-stick nature and compliance with FDA regulations make it the ideal choice.

By understanding these core properties and their inherent trade-offs, you can confidently specify PTFE for your most demanding sealing challenges.

Summary Table:

| Key Property | Benefit for Sealing Technology |

|---|---|

| Extreme Temperature Resistance (-200°C to +260°C) | Reliable performance in cryogenic to high-heat processes. |

| Chemical Inertness | Resists degradation from acids, alkalis, and solvents. |

| Low Coefficient of Friction | Reduces wear and energy consumption in dynamic seals. |

| Material Creep (Cold Flow) | Conforms to surface imperfections for leak-free static seals. |

| Non-Stick & Barrier Properties | Ensures hygiene and protects against moisture and dust. |

Solve Your Toughest Sealing Challenges with KINTEK

Do you need a sealing solution that can withstand extreme temperatures, aggressive chemicals, or demanding dynamic applications? The unique properties of PTFE make it the premier choice, and KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact performance your application requires.

Let us help you engineer the perfect seal. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F